When it comes to transferring power from engine to wheels, the driveshaft is the unsung hero of vehicle performance. But traditional steel driveshafts have always been a compromise—strong enough but heavy, durable but unforgiving. That’s where carbon fiber changes the game. At Xiamen Goldcattle, we’ve spent over a decade crafting custom carbon fiber driveshafts that eliminate those compromises, serving racing teams, performance shops, and manufacturers across the U.S. and Europe. Whether you need a track-ready upgrade or a production-ready solution, we build driveshafts that match your exact specifications.

Why Carbon Fiber Driveshafts Outperform the Rest

Any performance enthusiast knows the difference a quality driveshaft makes. Carbon fiber delivers advantages no metal can match:

- Up to 50% lighter than steel equivalents—reducing rotating mass for faster acceleration and better fuel efficiency

- Incredible strength-to-weight ratio that handles extreme torque without flexing or warping

- Superior fatigue resistance—carbon fiber doesn’t suffer from metal fatigue, even under constant stress

- Natural vibration damping that reduces noise and harshness compared to steel

- Corrosion resistance that outlasts metal in harsh environments, from race tracks to off-road trails

For performance applications where every ounce and every millisecond counts, carbon fiber driveshafts are a game-changer.

Our Custom Carbon Fiber Driveshaft Capabilities

We don’t do “one-size-fits-all”—every driveshaft is engineered for your specific application:

Our design team starts with your exact requirements: vehicle type, power output, length, diameter, and connection types (flanges, yokes, or custom interfaces). We use advanced FEA (Finite Element Analysis) to simulate performance before production, ensuring the driveshaft handles your maximum torque with a 200% safety margin.

Our design team starts with your exact requirements: vehicle type, power output, length, diameter, and connection types (flanges, yokes, or custom interfaces). We use advanced FEA (Finite Element Analysis) to simulate performance before production, ensuring the driveshaft handles your maximum torque with a 200% safety margin.

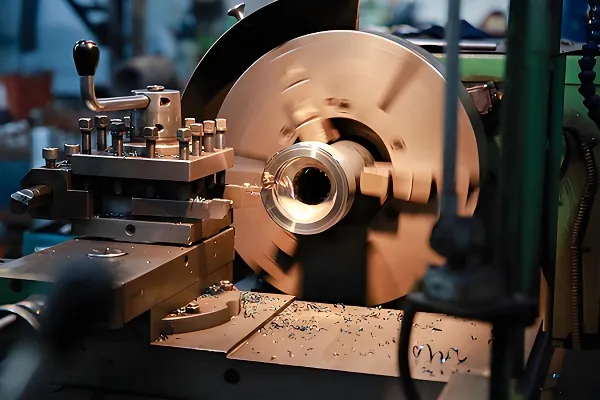

Production happens in our specialized carbon fiber facility, where we use aerospace-grade manufacturing processes:

- Precision filament winding that controls fiber orientation for optimal strength (we can adjust angle and layer density for specific torque requirements)

- High-pressure resin infusion that eliminates voids for consistent strength throughout the shaft

- Computer-controlled curing in industrial autoclaves that ensures perfect resin bonding

We handle all lengths from 300mm to 2500mm, with diameters ranging from 70mm to 150mm. Need a specific balance specification? We achieve dynamic balance to G2.5 standards at 3000 RPM, critical for high-speed applications.

Turnaround times are surprisingly fast for such precision work: custom designs approved in 3-5 days, prototypes ready in 2-3 weeks, and production runs scaled to your timeline.

Materials & Construction That Deliver Results

We only use top-tier materials that meet aerospace and motorsports standards:

- T700 and T800 carbon fiber for the perfect balance of strength and weight (we can use T1000 for extreme applications)

- High-temperature epoxy resins rated for continuous use up to 180°C (ideal for high-performance engines)

- Metal end fittings machined from 7075 aluminum or 304 stainless steel, depending on your corrosion and strength needs

- Optional wear sleeves and protective coatings for off-road or harsh environment use

Every component is selected to work together as a system, not just assembled parts. Our manufacturing process controls fiber direction, resin content, and curing parameters with precision that standard metal driveshafts can’t match.

Quality Control That Meets Racing Standards

In high-performance applications, failure isn’t an option—that’s why our quality process is rigorous:

- ISO 9001:2015 certified manufacturing with full traceability for every component

- 100% ultrasonic inspection to detect any internal defects in the carbon fiber structure

- Torque testing on every production driveshaft (up to 3000Nm capacity in our test lab)

- Dynamic balancing on computerized machines with laser precision

- Material certification provided with every order, including fiber type, resin batch, and test results

We document every step of production, so you know your driveshaft meets not just your specifications, but our own demanding standards.

Industries We Serve with Custom Driveshafts

Our carbon fiber driveshafts excel in applications where performance and reliability matter most:

- Motorsports (road racing, drag racing, rally, and off-road competition)

- High-performance street vehicles (sports cars, muscle cars, and modified imports)

- Commercial vehicles (where weight reduction improves fuel efficiency)

- Specialty equipment (agricultural machinery, industrial vehicles, marine applications)

- Electric vehicles (where reducing rotating mass maximizes range and performance)

No matter your application, we understand the specific demands your driveshaft will face.

Real-World Success Stories

The proof is in the performance—here’s how our driveshafts have delivered:

Rally Racing Driveshafts

A European rally team was struggling with steel driveshaft failures during endurance events. Their 350hp rally car needed a driveshaft that could handle extreme torque, constant vibration, and off-road abuse. We designed a 100mm diameter T800 carbon fiber driveshaft with reinforced end fittings. The new driveshaft reduced rotating mass by 4.2kg, improved acceleration times by 0.3 seconds per stage, and completed the full rally season without failure—something their previous steel shafts couldn’t achieve.

Performance Street Car Upgrade

A U.S. specialty manufacturer needed a drop-in carbon fiber driveshaft for their limited-edition muscle car. The factory steel unit was heavy and created driveline vibration at high speeds. Our custom driveshaft matched the original dimensions but reduced weight by 55%. We added vibration damping features and balanced to G1.0 standards. Customer testing showed improved quarter-mile times and eliminated the 75mph vibration issue—now standard equipment on their $150,000+ vehicles.

Commercial Vehicle Efficiency Upgrade

A logistics company wanted to improve fuel efficiency in their delivery trucks. We designed a custom carbon fiber driveshaft for their medium-duty trucks that reduced weight by 8kg per vehicle. Over 100,000 miles of testing showed a 2.3% improvement in fuel economy—saving thousands in fuel costs annually across their fleet. The driveshafts also required zero maintenance compared to steel units that needed periodic balancing.

Why Teams and Manufacturers Choose Us

After a decade in carbon fiber driveshafts, we’ve built our reputation on these fundamentals:

- We speak your language—our engineers understand both carbon fiber technology and vehicle dynamics

- Custom design expertise that turns your requirements into a driveshaft that performs better than expected

- Dedicated support for U.S. and European clients, including technical assistance and on-time delivery guarantees

- Small batch production capabilities for racing teams, plus scalable production for manufacturers

- Fast response times for quotes and technical questions (usually within 24 hours)

Ready to Upgrade Your Driveshaft?

Need a custom carbon fiber driveshaft for your application? Send us your vehicle specs, power output, and performance goals. Our engineering team will provide a detailed design proposal and quote within 48 hours, including FEA simulations and material recommendations. Whether you’re building a race car, upgrading a performance vehicle, or improving commercial fleet efficiency, we’ll create a driveshaft that delivers the power, performance, and reliability you need.