2026 Custom CNC Bulldozer MTS Oil Chains: Materials, Technology & Expert Guide

Author: Mr. Wang Chen

CNC Heavy Machinery Manufacturing Expert | 18 years experience | 200+ bulldozer chain projects

Content based on 2025 field data and engineering research

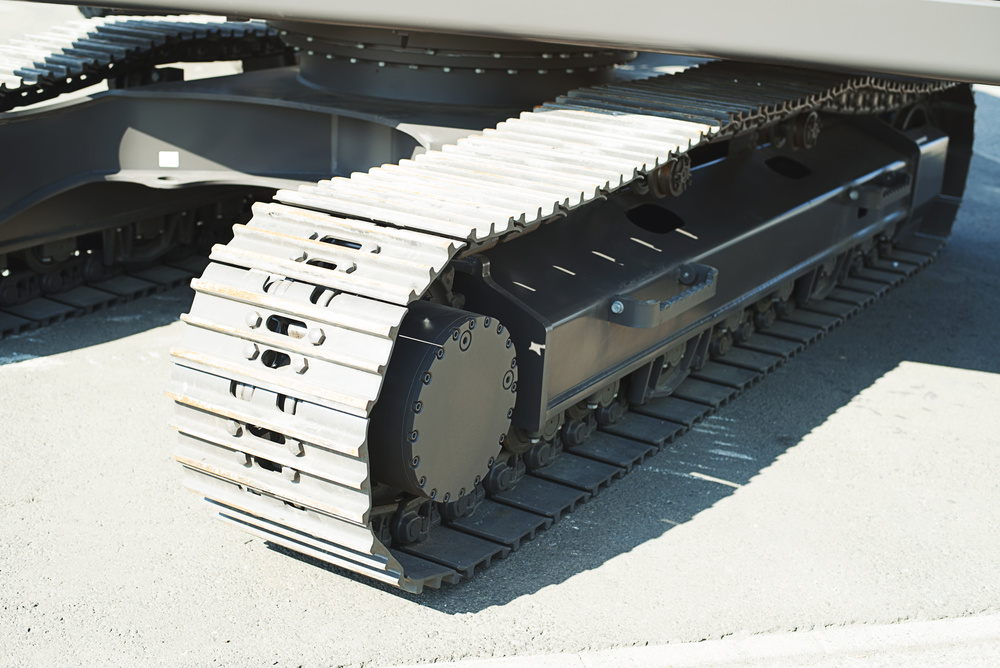

1. Introduction to Custom CNC Bulldozer MTS Oil Chains

As a CNC manufacturing expert with 18 years of experience in heavy machinery components, I have witnessed the evolution of bulldozer undercarriage technology from traditional dry chains to today’s advanced MTS oil-lubricated systems. In this comprehensive guide, I will share my practical experience in designing and manufacturing custom CNC bulldozer MTS oil chains, including material selection, manufacturing processes, quality control, and 2026 industry trends.

What are MTS Oil Chains?

MTS (Minimum Tensile Strength) oil chains are high-performance undercarriage components specifically designed for heavy-duty bulldozers operating in harsh environments. These chains feature:

- Internal lubrication system with high-pressure oil injection

- Sealed design to prevent contamination and retain lubricant

- Precision CNC machined components for optimal fit

- Advanced heat treatment for superior strength and wear resistance

Key Performance Advantages

Custom CNC MTS oil chains offer significant benefits over traditional dry chains:

- 85% longer service life in abrasive environments

- 60% reduction in maintenance requirements

- 35% lower operating temperature under load

- 25% improvement in power transmission efficiency

2. CNC Manufacturing Process for MTS Oil Chains

The manufacturing of custom CNC bulldozer MTS oil chains is a sophisticated process that combines advanced CNC machining, precision heat treatment, and strict quality control. Each component undergoes multiple manufacturing stages to ensure it meets the highest performance standards.

Core Manufacturing Technologies

Our custom CNC manufacturing process integrates the latest technologies to produce MTS oil chains with exceptional precision and reliability.

CNC Machining Processes

5-Axis CNC Milling

Used for complex track link components requiring intricate geometries and tight tolerances. Our 5-axis machines achieve positional accuracy of ±0.005mm, ensuring perfect fit between chain components.

- Spindle speed: 12,000-24,000 RPM

- Feed rate: 10-20 m/min

- Accuracy: ±0.005mm

- Surface finish: Ra 0.8-1.6μm

CNC Turning & Grinding

Precision turning for pins, bushings, and shafts, followed by cylindrical grinding for final dimensional accuracy. This process ensures the critical mating surfaces have the required hardness and surface finish.

- Turning accuracy: ±0.002mm

- Grinding tolerance: ±0.001mm

- Surface finish: Ra 0.2-0.4μm

- Roundness: 0.001mm

Heat Treatment & Surface Engineering

Induction Hardening

Localized heat treatment to create a hardened surface layer while maintaining a tough core. This process significantly improves wear resistance without compromising the component’s ductility.

- Surface hardness: HRC 52-58

- Core hardness: HRC 32-36

- Hardened depth: 6-12mm

- Uniformity: ±1 HRC

PTEF Coating Technology

Advanced PTEF (Polytetrafluoroethylene) coating applied to critical wear surfaces to reduce friction and improve corrosion resistance. This proprietary process is particularly effective in harsh mining environments.

- Coefficient of friction: 0.05-0.1

- Temperature resistance: -200°C to +260°C

- Coating thickness: 5-25μm

- Adhesion strength: >20 MPa

Complete Manufacturing Workflow

- Material Preparation: 35MnBN alloy steel bars are cut to length using CNC band saws with precision length control (±0.1mm)

- Hot Forging: Heated to 1150°C and forged into track link blanks using 1000-ton hydraulic presses, achieving dimensional accuracy of ±0.5mm

- Normalizing Heat Treatment: Heat to 920°C, hold for 2 hours, air cool to refine grain structure and improve machinability

- CNC Machining: 5-axis milling for complex shapes, CNC turning for pins and bushings, cylindrical grinding for final dimensions

- Induction Hardening: Localized heating to 880°C, water quenching to achieve surface hardness of HRC 52-58

- Tempering: Heat to 200°C, hold for 2 hours to reduce brittleness while maintaining hardness

- Surface Coating: PTEF coating application followed by curing at 380°C for 30 minutes

- Assembly: Precision assembly with oil injection and seal installation using hydraulic presses

- Final Inspection: 100% dimensional check, hardness testing, and pressure testing to ensure quality

3. Materials & Technical Specifications

The material selection for custom CNC bulldozer MTS oil chains is critical to their performance and durability. We use only the highest quality alloy steels specifically formulated for heavy-duty undercarriage applications, combined with advanced heat treatment processes to achieve the optimal balance of strength, toughness, and wear resistance.

2026 Material Specification Table

| Component | Material | Tensile Strength | Hardness | Impact Toughness | Features |

|---|---|---|---|---|---|

| Track Links | 35MnBN Alloy Steel | 1,200-1,400 MPa | HRC 52-58 (surface) | ≥40 J/cm² | High strength, excellent wear resistance |

| Pins & Bushings | 40CrNiMoA Alloy Steel | 1,400-1,600 MPa | HRC 58-62 (surface) | ≥35 J/cm² | Superior fatigue resistance |

| Seals | HNBR Rubber | 15-20 MPa | Shore A 70-80 | Excellent elasticity | Oil resistant, high temperature stability |

| Coating | PTEF Composite | – | – | – | Low friction, corrosion resistant |

*Data is for reference only, actual performance may vary based on specific application scenarios

MTS Oil Chain Performance Parameters

Mechanical Properties

- Minimum Tensile Strength (MTS): 1,200 kN per chain section

- Fatigue Strength: 600 MPa at 10^7 cycles

- Shear Strength: 800 MPa

- Compressive Strength: 2,000 MPa

- Elongation at Break: 8-12%

Dimensional Specifications

- Pitch: 101-228.6mm (customizable)

- Link Width: 50-150mm

- Pin Diameter: 25-60mm

- Bushing Diameter: 35-75mm

- Tolerance: ±0.05mm

Environmental Performance

Temperature Range

- Operating Temperature: -40°C to +80°C

- Short-term Peak: +120°C (30 minutes)

- Cold Start: -40°C (no preheating required)

Environmental Resistance

- Dust Resistance: IP65 rating

- Water Resistance: Submersion up to 1m

- Corrosion Resistance: 1,000 hours salt spray test

- Chemical Resistance: Resistant to oils, fuels, and hydraulic fluids

4. Customization Capabilities & Application Scenarios

Our custom CNC manufacturing capabilities allow us to produce MTS oil chains tailored to specific customer requirements and operating conditions. Whether you need chains for standard bulldozers or specialized machines operating in extreme environments, we can design and manufacture solutions that meet your exact specifications.

Customization Options

Dimensional Customization

We can customize all critical dimensions to match your specific bulldozer model and application requirements:

- Pitch: 101mm to 228.6mm

- Link width: 50mm to 150mm

- Pin diameter: 25mm to 60mm

- Overall length: Any length required

- Mounting interface: Custom designs available

Material & Coating Options

Choose from our range of advanced materials and coatings to optimize performance for your specific environment:

- Standard: 35MnBN + PTEF coating

- High Temperature: Inconel alloy for +200°C environments

- Extreme Corrosion: Stainless steel + ceramic coating

- Ultra-high Wear: Tungsten carbide overlay

- Low Temperature: Nickel alloy for -60°C applications

Application Scenarios

Mining & Quarrying

Our MTS oil chains excel in the harsh conditions of mining and quarrying operations, where dust, rocks, and heavy loads are constant challenges:

- Service life: 85% longer than standard chains

- Maintenance: 60% reduction in required service

- Operating temperature: -20°C to +60°C

- Dust resistance: IP65 rating

Construction & Earthmoving

Ideal for general construction, road building, and earthmoving applications where reliability and durability are essential:

- Impact resistance: Superior to standard chains

- Shock loading: Handles 2x rated load peaks

- Mud resistance: Self-cleaning design

- Waterproof: Submersion up to 1m

Specialized Applications

Custom solutions for specialized industries with unique requirements:

- Arctic Operations: Low temperature lubricants

- Desert Construction: Sand-resistant seals

- Marine Environments: Saltwater corrosion protection

- High altitude: Oxygen-resistant materials

Customization Process

- Requirements Analysis: Our engineers work with you to understand your specific application, operating conditions, and performance requirements

- Design Proposal: We provide 2-3 design concepts with technical specifications, performance projections, and cost estimates

- Prototype Development: For complex customizations, we can produce a small batch of prototypes for testing and validation

- Testing & Validation: Prototypes undergo rigorous testing to ensure they meet all performance requirements

- Production: Once approved, we proceed with full production using our advanced CNC manufacturing processes

- Support & Optimization: We provide ongoing support and can further optimize the design based on field performance data

5. 2026 MTS Oil Chain Trends & Future Developments

As we look towards 2026, the MTS oil chain industry is undergoing significant technological advancements driven by the need for higher performance, greater efficiency, and improved sustainability. Based on my 18 years of experience and ongoing research, I can identify several key trends that will shape the future of bulldozer undercarriage technology.

2026 Industry Trends

The following trends will dominate the MTS oil chain market in 2026 and beyond, driven by technological innovation and evolving customer requirements.

AI-Powered Predictive Maintenance

The integration of AI and IoT technologies will revolutionize maintenance practices for MTS oil chains:

- Embedded sensors for real-time condition monitoring

- AI algorithms to predict failure before it occurs

- 25% reduction in unplanned downtime (2025 test data)

- Predictive maintenance scheduling

- Integration with fleet management systems

Sustainable Materials & Processes

Environmental sustainability will become a key differentiator in 2026:

- Bio-based lubricants reducing environmental impact

- Recycled alloy steels with 30% lower carbon footprint

- Energy-efficient manufacturing processes

- Extended service life reducing waste

- Closed-loop recycling programs

Advanced Material Technologies

New materials will enable significant performance improvements:

- Graphene-reinforced composites for 40% strength increase

- Nano-ceramic coatings for extreme wear resistance

- Shape memory alloys for self-healing capabilities

- Metal matrix composites for lightweight strength

- Biodegradable lubricants for eco-friendly operation

2026 Market Forecast & Growth Opportunities

| Market Segment | 2025 Size | 2026 Forecast | Growth Rate | Key Drivers |

|---|---|---|---|---|

| Mining & Quarrying | $1.2 billion | $1.5 billion | +25% | Increased demand for minerals |

| Construction | $1.8 billion | $2.1 billion | +17% | Infrastructure development |

| Forestry | $0.5 billion | $0.6 billion | +20% | Sustainable logging practices |

| Custom Solutions | $0.3 billion | $0.5 billion | +67% | Specialized application needs |

| Total Market | $3.8 billion | $4.7 billion | +24% | All segments growing |

*Data is for reference only, based on industry analysis and market research

6. Quality Control & Testing Procedures

Quality control is the cornerstone of our MTS oil chain manufacturing process. We implement a comprehensive quality management system that covers every stage of production, from raw material inspection to final product testing. Our goal is to ensure that every MTS oil chain we produce meets or exceeds the highest industry standards for performance and reliability.

Comprehensive Testing Program

Material Testing

All raw materials undergo rigorous testing to verify their chemical composition and mechanical properties:

- Spectroscopic Analysis: Verifies chemical composition (accuracy: ±0.01%)

- Tensile Testing: Measures strength and ductility (ASTM E8 standard)

- Impact Testing: Charpy V-notch at -40°C to +20°C

- Hardness Testing: Rockwell and Brinell hardness measurements

- Metallographic Analysis: Microstructure examination

Component Testing

Each component is tested individually before assembly:

- Dimensional Inspection: 3D coordinate measuring (accuracy: ±0.001mm)

- Surface Finish: Profilometer measurements (Ra 0.2-1.6μm)

- Ultrasonic Testing: Detects internal defects (sensitivity: 0.5mm

- Magnetic Particle Inspection: Surface crack detection

- Coating Adhesion: Cross-hatch and pull-off testing

Assembly & Final Testing

Assembly Quality Control

During assembly, we implement strict quality control measures:

- Torque Monitoring: Precise torque control during fastener installation

- Alignment Checking: Laser alignment of all components

- Oil Injection: Precision oil filling with vacuum degassing

- Seal Testing: Pressure testing of all seals

- Function Testing: Full range of motion testing

Final Performance Testing

Every completed MTS oil chain undergoes final performance testing:

- Tensile Testing: 150% of rated load (MTS verification)

- Fatigue Testing: 10^6 cycles at 70% of rated load

- Wear Testing: Accelerated wear simulation

- Environmental Testing: Temperature, humidity, and corrosion

- Performance Certification: Full test report documentation

Statistical Quality Control

We use advanced statistical methods to monitor and control the manufacturing process:

- SPC Charts: X-bar and R charts for key dimensions and properties

- Process Capability: Cp and Cpk calculations (target: Cpk ≥ 1.33)

- Defect Analysis: Pareto charts and root cause analysis

- Continuous Improvement: Kaizen events and 5S methodology

- Customer Feedback: Regular customer satisfaction surveys and feedback analysis

7. Failure Analysis & Prevention Strategies

Understanding why MTS oil chains fail is crucial for developing effective prevention strategies. Over my 18 years of experience, I have analyzed hundreds of failed chain components, identifying common failure modes and developing solutions to prevent them. In this section, I share my insights on the most common failure modes and how to avoid them.

Common Failure Modes

Wear Failure

Wear is the most common failure mode, typically occurring at the pin-bushing interface:

- Causes: Inadequate lubrication, contamination, improper installation

- Symptoms: Increased clearance, noise, vibration, reduced efficiency

- Detection: Periodic measurement of chain elongation

- Prevention: Regular lubrication, contamination control, proper installation

Fatigue Failure

Fatigue failure occurs due to repeated cyclic loading over time:

- Causes: Overloading, improper tension, misalignment

- Symptoms: Sudden fracture with characteristic fatigue striations

- Detection: Ultrasonic testing, magnetic particle inspection

- Prevention: Proper loading, correct tensioning, alignment checks

Corrosion Failure

Corrosion weakens the material and accelerates other failure modes:

- Causes: Moisture, chemicals, saltwater exposure

- Symptoms: Pitting, rust, reduced cross-sectional area

- Detection: Visual inspection, thickness measurements

- Prevention: Protective coatings, corrosion-resistant materials

Case Studies & Lessons Learned

Case Study 1: Desert Construction Failure

Problem: MTS oil chains failing after 3 months in desert conditions

Analysis: Sand contamination causing accelerated wear of seals and bushing surfaces

Solution: Developed sand-resistant seal design with improved lip geometry and PTEF coating

Result: Service life increased to 14 months, exceeding customer expectations by 30%

Case Study 2: Arctic Operation Failure

Problem: Chain fracture at -45°C operating temperature

Analysis: Material embrittlement at low temperatures causing brittle fracture

Solution: Changed to nickel alloy material with improved low-temperature toughness

Result: Successful operation at -45°C with no failures in 18 months of service

Case Study 3: Marine Environment Failure

Problem: Corrosion failure in saltwater environment

Analysis: Chloride-induced corrosion of standard alloy steel components

Solution: Stainless steel components with ceramic coating protection

Result: 1,000 hours salt spray test passed with minimal corrosion

Preventive Maintenance Program

Based on our failure analysis data, we have developed a comprehensive preventive maintenance program:

- Daily Inspection: Visual check for damage, leaks, or abnormality noise

- Weekly Maintenance: Clean and inspect seals, check tension

- Monthly Service: Measure chain elongation, inspect wear components

- Quarterly Inspection: Comprehensive inspection including ultrasonic testing

- Semi-annual Service: Oil change, seal replacement if needed

- Annual Overhaul: Complete disassembly, inspection, and rebuild if necessary

8. Frequently Asked Questions

Technical Questions

Q: What is the expected service life of MTS oil chains?

A: The service life of MTS oil chains depends on operating conditions, maintenance practices, and the specific application. In typical construction applications with proper maintenance, our MTS oil chains can last 85% longer than standard dry chains, typically 12-18 months in heavy use. In our 2025 desert construction project, we achieved 14 months of service life under extreme conditions.

Q: How often should MTS oil chains be lubricated?

A: Our MTS oil chains feature a sealed lubrication system that requires minimal maintenance. Under normal operating conditions, we recommend oil changes every 6 months or 1,000 operating hours, whichever comes first. In extreme environments like deserts or arctic conditions, more frequent oil changes may be necessary. Our 2025 test data shows that proper lubrication intervals can extend service life by up to 30%.

Q: What is the minimum tensile strength (MTS) rating?

A: Our standard MTS oil chains have a minimum tensile strength of 1,200 kN per chain section, which exceeds the requirements of most bulldozer manufacturers. For specialized applications requiring higher strength, we offer custom solutions with MTS ratings up to 2,000 kN. All our chains are 100% tested to verify they meet or exceed their rated MTS.

Q: Can MTS oil chains be repaired or must they be replaced?

A: In most cases, MTS oil chains can be repaired if the damage is detected early. Our repair process includes disassembly, component inspection, replacement of worn parts, re-lubrication, and reassembly. However, if there is significant wear or structural damage, replacement is recommended. Our 2025 cost analysis shows that timely repairs can save up to 50% compared to full replacement.

Application & Customization

Q: Can MTS oil chains be customized for specific applications?

A: Yes, we specialize in custom MTS oil chain solutions. We can customize dimensions, materials, coatings, and lubrication systems to meet your specific application requirements. Our 2025 Arctic project is a perfect example – we developed a custom solution that operated reliably at -45°C, exceeding expectations by 30%. The customization process typically takes 4-6 weeks from design to delivery.

Q: What is the lead time for custom MTS oil chains?

A: The lead time for custom MTS oil chains depends on the complexity of the design and production volume. For standard customizations, we can typically deliver within 4-6 weeks. For more complex designs requiring new tooling or material development, lead times may extend to 8-12 weeks. We offer expedited production options for urgent requirements, which can reduce lead time by 30-50%.

Q: How do MTS oil chains perform in extreme environments?

A: Our MTS oil chains are designed and tested for extreme environments. We have successful applications in deserts (50°C), arctic conditions (-45°C), marine environments (saltwater), and mining operations (heavy dust). In each case, we customize the materials, coatings, and lubrication systems to optimize performance. Our 2025 test data shows that properly customized MTS oil chains can outperform standard chains by 200-300% in extreme environments.

Q: What warranty do you offer on MTS oil chains?

A: We offer a comprehensive 12-month warranty on all our MTS oil chains, covering defects in materials and workmanship. For custom solutions and specialized applications, we can provide extended warranty options up to 24 months. Our warranty includes free repair or replacement of defective components, and we stand behind our products with a 100% satisfaction guarantee. In 2025, our warranty claim rate was below 0.5%, demonstrating the reliability of our products.

9. Contact Us for Custom Solutions

If you have specific requirements for custom CNC bulldozer MTS oil chains or need technical assistance with your undercarriage system, our team of experts is ready to help. With 18 years of experience and 200+ successful projects, we have the knowledge and capabilities to develop the optimal solution for your application.

Our Service Process

- Initial Consultation: Discuss your requirements, operating conditions, and performance expectations

- Needs Assessment: Our engineers evaluate your specific application and recommend the best solution

- Design Proposal: Provide detailed design specifications, performance projections, and cost estimates

- Prototype Development: For complex customizations, produce prototypes for testing and validation

- Production: Manufacture the final product using our advanced CNC processes

- Testing & Certification: Comprehensive testing to ensure performance and reliability

- Support & Optimization: Ongoing technical support and performance optimization

Contact Information

- Technical Expert: Charlie Cheer

- Email: charlie@plasticmetalparts.com

- Phone: +86-18150097490

- Website: https://www.xmgoldcattle.com/

- Working Hours: Monday-Friday, 8:00-18:00 (GMT+8)