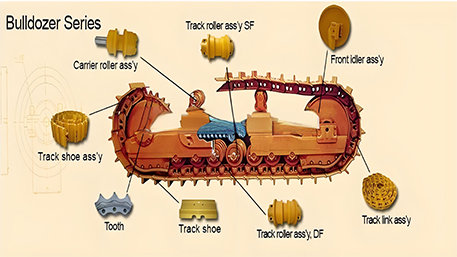

In the rocky mines of North America, the damp ports of Europe, the electric construction sites of Northern Europe, and the high-temperature outback of Australia, bulldozer sprockets face extreme operational challenges. Generic sprockets often fail prematurely due to poor fit, leading to inefficiency and frequent breakdowns. With 20 years of expertise in construction machinery drivetrain components, our team leverages CNC precision machining and end-to-end customization to create “application-specific sprockets” that ensure stable power transmission in the harshest environments.

I. Full Environment Adaptation: Engineered to Conquer Any working condition

- Structural Reinforcement: For U.S. western mine conditions with 200kN impact loads, tooth root fillets are increased from standard 3mm to 5mm, reducing stress concentration by 40% and improving fracture resistance by 30%.

- Interface Compatibility: A database covering 30+ global equipment brands (Caterpillar, Komatsu, Sany, etc.) ensures H7-class flange hole precision and ±0.02mm bolt hole distribution tolerance, eliminating installation misalignment and drivetrain noise.

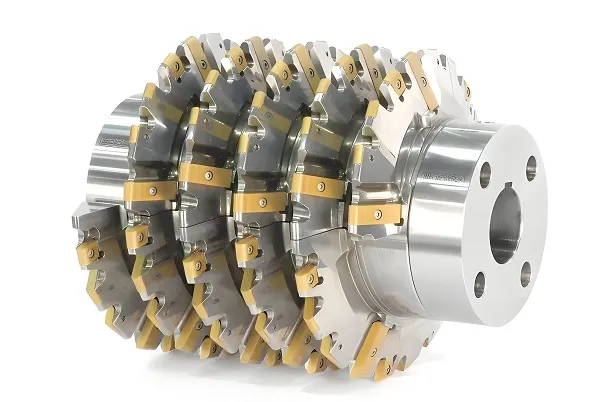

- Tooth Profile Precision: Machined in one setup on Mazak 5-axis machines, cumulative pitch error is controlled within ±0.02mm (better than GB ±0.05mm), tooth profile error ≤0.03mm, and meshing clearance with chains <0.1mm, achieving 98% transmission efficiency.

- Surface Treatment: High-speed grinding creates a mirror-finish surface (Ra≤0.8μm), combined with 0.5mm deep oil storage grooves, reducing dry friction by 90% and extending lubrication cycles to 200 hours (vs. 80 hours for traditional sprockets).

- Flexible Manufacturing: Equipped with ATC (Automatic Tool Changer) and APC (Automatic Pallet Changer), model switching for different sprocket specifications (tooth count/pitch/hole diameter) takes just 15 minutes. Small batches (1-50 pieces) are delivered in 7 working days, supporting 20+ global language drawings.

- Quality Traceability: Each sprocket embeds an RFID chip recording material batch (e.g., ThyssenKrupp premium steel), heat treatment curves (quenching temperature 850℃±10℃), and test data (dynamic balance G6.3 class). Scan to view the “digital twin” model for global quality traceability.

- Multilingual engineering team (English/German/French) provides free working condition surveys.

- Deliver multilingual Custom Solution Proposals within 24 hours, including:▶ Material compatibility analysis (e.g., 42CrMo vs. 6061-T6 aluminum)▶ Cost breakdown (material/machining/testing ratios)▶ Timeline planning (key milestones for design/machining/delivery)

- ② Collaborative R&D:

- Support drawing-based machining (error correction rate 99%), joint design (site surveys to optimize tooth profiles, such as +40% life improvement for Canadian oil sands), and reverse engineering (50% cost reduction for import substitution).

- ③ Delivery Assurance:

- 8 global warehouses (covering North America, Europe, Australia) offer customized inventory hosting for strategic clients.

- 48-hour air freight for urgent orders, reducing downtime losses by 80%.

- Canadian Oil Sands: Thickened tooth surface hardening + oil-repellent coating extended sprocket life from 1000 to 1800 hours, cutting annual maintenance costs by 60%.

- German Wind Energy: Custom aluminum sprockets with CNC dynamic balancing reduced noise from 95dB to 82dB, compliant with EU Machinery Directive (2006/42/EC).

- 7-Dimensional Inspection:Comprehensive testing of 21 indicators including material composition (spectrometer, element deviation ≤0.05%), hardness gradient (metallographic microscope, carburizing layer depth error ±0.05mm), tooth profile accuracy (CMM, spatial error ≤0.02mm), and dynamic balance (residual unbalance ≤5g·cm/kg).

- International Certifications:CE (EU), ASME (USA), and ISO 9001 compliant. Each sprocket undergoes 200-hour working condition simulation (including 1000 冲击 loads) and offers 3-month free trials in extreme environments.

- 12 international patents (e.g., anti-corrosion process for high-humidity environments).

- Participation in 3 ISO standards (covering sprocket heat treatment and accuracy testing).

- Overseas R&D centers equipped with material fatigue testers and 3D scanners for localized technical validation.

- 50+ imported CNC machines (Mazak, Haas, Mori Seiki), annual capacity 100,000 units, supporting special standards like AAR M-1003 (North American railway).

- Closed-die forging increases material utilization to 92%, with fiber flow alignment ≥95% for 30% better fatigue resistance.

- Custom design eliminates “over-engineering,” reducing costs by 30%-50% compared to local European/North American brands.

- Graded material options (Basic/Enhanced/Top-End) with multi-currency support (USD/EUR/GBP).

- 7×24 multilingual support (English/German/French/Spanish), providing international-standard installation videos and maintenance manuals (including OSHA guidelines).

- After-sales teams in 15 countries, with 48-hour on-site response for major European/North American construction regions.