Opening: When Every Dig Counts – The Hidden Cost of Compromised Wear Parts

In the unforgiving worlds of mining, construction, and infrastructure development, your excavator is more than a machine—it’s your profit engine. But standard bucket teeth and wear parts? They’re the weak link.

- Why settle for 500 hours of operation when others achieve 800+?

- How do you conquer abrasive rock, sticky clay, or frozen soil without constant downtime?

- What if wear parts weren’t just replaced but tailored to your unique digging conditions?

Welcome to the future of excavation: custom excavator bucket teeth and wear parts designed to turn harsh operating conditions into competitive advantage.

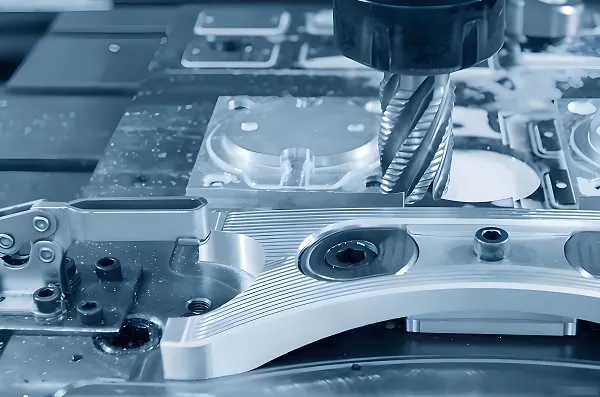

I. Customization Technology: From Material to Geometry – Redefining Wear Resistance

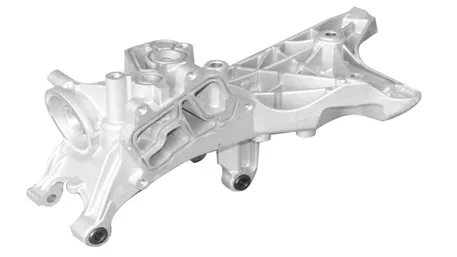

Our customization framework combines material science, geometric optimization, and precision manufacturing to create parts that outlast, outperform, and out-dig generic solutions.

1. Material Engineering: The Foundation of Durability

- High-Chromium Alloys (e.g., ASTM A532 Grade IIIB)

- Composition: 25–30% Cr, 2–3% Mo, 1.5–2% C, hardness HRC 58–62.

- Advantage: 40% higher abrasion resistance than standard manganese steel, ideal for iron ore and granite excavation.

- Ceramic-Reinforced Composites

- Structure: Tungsten carbide (WC) particles embedded in a nickel-chromium matrix.

- Performance: Withstands impact forces up to 50,000N, reducing tip breakage by 30% in shale and sandstone applications.

2. Geometric Precision: Tailored for Your Digging Style

- Tip Angle Optimization

- 20° for penetration-focused tasks (e.g., hard rock), increasing bite force by 25%.

- 35° for material retention (e.g., sticky clay), minimizing spillage during loading.

- Root Reinforcement Design

- Finite Element Analysis (FEA)-optimized root geometry reduces stress concentration by 40%, extending shank life from 1,000 to 1,400 hours in cyclic loading operating conditions.

3. Surface Treatment: Layers of Protection

- Laser Cladding

- Deposits a 1–3mm layer of cobalt-chromium alloy on high-wear areas, increasing surface hardness to HV 1,200 and wear life by 50%.

- Thermal Spray Coating

- Alumina-zirconia coatings provide a 0.3mm corrosion barrier, ideal for marine construction and salt-rich environments.

II. Full-Scenario Applications: Where Generic Parts Fail, Custom Parts Excel

| Industry | Challenge | Custom Solution | Data Backed Result |

|---|---|---|---|

| Mining | Hard rock & high-impact loads | Tungsten carbide-tipped teeth with shock-absorbing shanks | 800+ hours of operation (vs. 500 hours for standard) |

| Construction | Mixed soil & repetitive digging | Curved-edge bucket lips with wear-resistant inserts | 20% faster cycle times, 30% less fuel consumption |

| Wetlands | Corrosive mud & low bearing capacity | Stainless steel alloy teeth with self-cleaning profiles | 2x longer life in saltwater and acidic environments |

Case Studies

-

Iron Ore Mine in Australia

- Problem: Standard teeth failed every 400 hours in magnetite ore.

- Solution: Custom high-chromium teeth with dual-layer cladding.

- Outcome: 900 hours of operation, downtime reduced by 60%, annual cost savings of $280,000 per excavator.

-

Urban Construction in Tokyo

- Challenge: Frequent digging in compacted gravel and concrete debris.

- Solution: Narrow-profile teeth with serrated edges for precise penetration.

- Result: 35% faster material break-up, meeting tight project deadlines without tip fractures.

III. Technological Trends: Smarter, Stronger, More Sustainable

-

IoT-Enabled Wear Monitoring

- Embedded strain sensors track real-time impact forces and wear rates, sending alerts when replacement is needed (accuracy ±5%).

- Example: A mining fleet reduced unplanned downtime by 45% using predictive maintenance data.

-

Lightweight Design for Efficiency

- Aluminum-alloy reinforced shanks (30% lighter than steel) reduce excavator arm load, improving fuel efficiency by 15% without compromising strength.

-

Circular Manufacturing

- 85% of worn parts are reconditioned via laser remanufacturing, cutting material waste and costs by 40% compared to traditional replacement.

IV. FAQ: Your Questions Answered

-

How long does the customization process take?

- 7–10 days for design (including FEA analysis), 15–20 days for production. Urgent orders available in 10 days with priority manufacturing.

-

Can you match existing OEM specifications?

- Yes. We reverse-engineer parts to fit brands like Caterpillar, Komatsu, John Deere, with dimensional accuracy within 0.05mm.

-

What’s the cost difference vs. standard parts?

- 20–30% higher upfront, but 2–3x longer lifespan and 40% lower total cost of ownership (TCO) due to reduced downtime and fuel savings.

V. Customer Testimonials

-

“Outlasted OEM parts by 50% in shale excavation” – BHP Billiton Site Manager

“Our custom teeth withstood 750 hours in Marcellus shale, while standard ones failed at 500. Worth every dollar.” -

“No more tip breakage in frozen soil” – Vinci Construction Supervisor

“The reinforced root design eliminated fractures during winter operations. Productivity jumped 25%.” -

“Corrosion-proof in marine projects” – China Communications Construction

“Stainless steel alloy teeth lasted 18 months in seawater—3x longer than previous parts. A game-changer for offshore work.”

VI. Ready to Transform Your Excavation Performance?

In excavation, one size never fits all. Whether you’re breaking granite in a quarry, moving debris in a cityscape, or working in corrosive wetlands, your equipment deserves parts that don’t just meet standards—they set them.

Here’s what we offer:

✅ 15+ Years of Expertise: 1,000+ custom wear part designs for global mining, construction, and infrastructure clients.

✅ End-to-End Engineering: From on-site operating conditions analysis to CAD modeling, material testing, and installation support.

✅ No Compromise on Quality: Every part undergoes 12-point testing, including impact resistance (ASTM D256), hardness (Rockwell C), and dimensional precision (ISO 2768).

✅ 15+ Years of Expertise: 1,000+ custom wear part designs for global mining, construction, and infrastructure clients.

✅ End-to-End Engineering: From on-site operating conditions analysis to CAD modeling, material testing, and installation support.

✅ No Compromise on Quality: Every part undergoes 12-point testing, including impact resistance (ASTM D256), hardness (Rockwell C), and dimensional precision (ISO 2768).

Tell us your challenge:

Share your excavation site conditions, material types, and performance goals. Our engineers will craft a solution that turns wear and tear into a competitive edge—because in your business, downtime is not an option.

Share your excavation site conditions, material types, and performance goals. Our engineers will craft a solution that turns wear and tear into a competitive edge—because in your business, downtime is not an option.

Start the conversation today – let’s design wear parts that work as hard as you do.