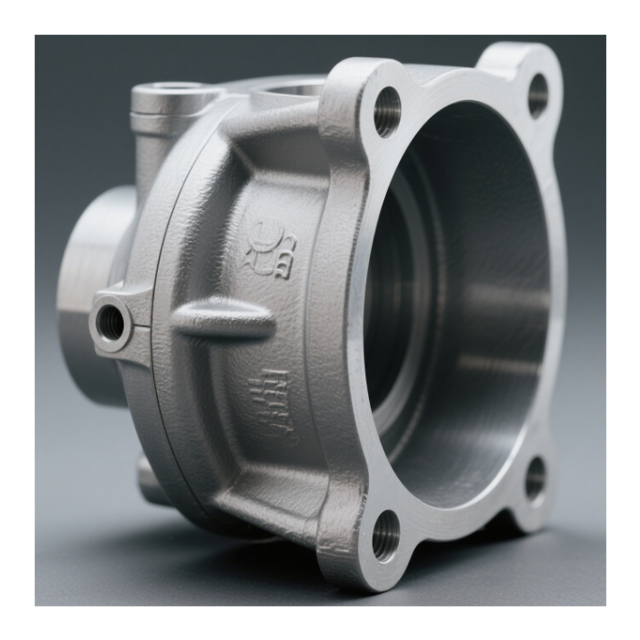

With 25 years of expertise in construction machinery, Xiamen Goldcattle leverages CNC precision machining to pioneer an “application-specific customization” model. From the frozen mines of Siberia to the high-temperature deserts of the Middle East, our custom excavator buckets are engineered to reduce system failure rates by 60% and extend wear life by 80% in extreme environments, redefining equipment reliability standards.

- Heavy Load Reinforcement: For Australian mining buckets, base plate thickness increases by 20%, tooth sockets are thickened by 10%, boosting impact resistance by 40% and reducing fracture risk by 50%.

- Environmental Adaptation: Arctic-grade low-temperature steel (with Ni alloy) maintains impact absorption ≥30J at -50°C; coastal wetland buckets use 316L stainless steel side plates passing 1,500+ hours of salt spray testing.

- Material Properties: Swedish-imported ultra-high strength steel (tensile strength ≥1,500MPa, HB500 hardness), 3x more wear-resistant than standard steel.

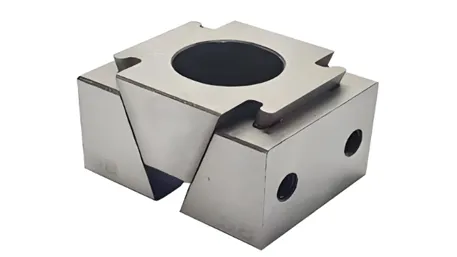

- Processing Advantages:

- CNC laser cutting enhances tooth socket welding strength by 50%, achieving 2,000+ hours of service life in mining operations.

- Step-shaped bucket edge design reduces penetration resistance, improving digging efficiency by 15%.

- Material Properties: Cu/P-alloyed weathering steel with 50% lower atmospheric corrosion rate, paired with Dacromet coating for dual protection.

- Processing Advantages:

- Hot-dip galvanizing forms a 20μm dense coating, passing 2,000-hour salt spray testing with zero red rust.

- CNC-precision drilled drainage holes reduce mud retention by 80%, preventing electrochemical corrosion.

- Material Properties: Cr/Mn/Si alloy steel with 600°C oxidation resistance, retaining ≥85% tensile strength at 400°C.

- Processing Advantages:

- 100μm ceramic coating (HV1200 hardness) reduces dust embedding by 60%.

- Self-cleaning tooth profile via 5-axis CNC machining increases dust passage rate by 50%, minimizing jamming.

- Material Properties: Aerospace-grade aluminum (density 2.8g/cm³, tensile strength ≥524MPa) for significant weight reduction.

- Processing Advantages:

- Anodized 25μm oxide film triples weather resistance, with self-lubricating coating reducing friction to 0.15μ.

- CNC precision achieves 0.8mm thin-wall forming, limiting high-speed rotation noise to ≤85dB for urban infrastructure operations.

- Tooth Forming: 5-axis machining ensures tooth pitch tolerance ±0.03mm and meshing clearance ≤0.1mm, achieving 97% digging force transmission efficiency.

- Pin Shaft Processing: Cold extrusion achieves surface roughness Ra≤0.4μm and IT6-level fit precision, extending lubrication cycles to 300 hours.

- Automated Production: 12-process continuous machining boosts small-batch efficiency by 60%, with 24-hour emergency order response.

- Needs Diagnosis: Multilingual customization proposals delivered within 48 hours, including material selection, cost breakdown, and life cycle predictions.

- Collaborative R&D:

- Drawing-based machining (98% error correction), joint design (35% life improvement via on-site optimization), and 3D printing prototyping (7-day complex structure validation).

- Global Delivery: 100+ global partners with deep strategic cooperation in Europe and North America, ensuring localized service responsiveness.

|

Project Scenario

|

Custom Solution

|

Performance Improvement

|

|

Russian Frozen Mine

|

Low-Temp Alloy Steel Bucket + Anti-Fracture Treatment

|

2,000 hours of fracture-free operation at -50℃, doubled service life

|

|

Middle Eastern Desert

|

Ceramic-Coated Wear-Resistant Bucket

|

Wear <0.5mm after 18 months, 100% above industry standards

|

|

Dutch Coastal Wetland

|

316L Stainless Steel Side Plates + Oil-Repellent Coating

|

90% reduction in saltwater corrosion rate, 55% annual maintenance cost savings

|

- 15 proprietary patents in CNC machining and material treatment

- Involvement in 2 ISO international standards (including SAE J296 bucket capacity measurement)

- Extreme environment lab supporting -60℃ to 500℃ simulation testing

- 40+ imported CNC machines (Swiss Tornos/Japanese Mazak)

- 800,000 units annual capacity supporting SAE J1975/EN 4674/national standards

- IT6-level dimensional accuracy with 99.8% factory pass rate

- 30%-45% cost reduction compared to European/North American brands

- Graded product lines (Basic/Enhanced/Top-End) with MOQ as low as 10 units

- Free working condition adaptation plans and cost estimation

❓ Q1: Can non-standard excavators get custom buckets?

✅ Provide equipment model, bucket capacity parameters, and installation drawings for free 3D modeling compatibility assessment, ensuring 100% fit.

❓ Q2: What’s the lead time for small-batch orders?

✅ Sample orders (10-50 units): 7-10 daysBulk orders (50-200 units): 15-20 daysFlexible production lines support rapid model switching.

❓ Q3: Do you provide international certifications?

✅ CE, ASME, and ISO 9001 certified. Materials/processes comply with EU RoHS/REACH, facilitating global customs clearance.