Opening: When Connecting Rods Become the Weak Link – How Generic Parts Sabotage Your Excavator

In the rugged landscapes of post-blast mining sites, swampy mud operations, or the steel jungles of high-rise demolition, the H-type connecting rod is the backbone of your excavator, enduring cyclic loads that test its limits. But generic rods hide costs that erode your profitability:

- Downtime from fatigue fractures: $3,000 per hour lost, with a replacement cycle of just 1,500 hours?

- Precision loss from pin wear: Material grabbing deviation exceeding 5%, reducing efficiency by 12%?

- Energy waste from redundant weight: 15% heavier than optimal design, burning 300 extra liters of fuel monthly?

It’s time for a breakthrough: custom H-type connecting rods, engineered through material innovation, structural optimization, and operating conditions – specific design to transform a “vulnerable part” into a “durability core.” Redefine reliability and economy in heavy-duty operations.

I. Customization Technology: A 3D Overhaul from Material to Structure

Our custom design framework addresses the “load-environment-efficiency” triad, upgrading materials, reinforcing structures, and enhancing surface treatments to outperform OEM standards.

1. Material Engineering: Built for Extreme Loads

- High-Strength Quenched & Tempered Steel (e.g., 42CrMo4)

- Composition: 0.38–0.45% C, 1.2–1.5% Cr, 0.15–0.3% Mo, tensile strength ≥1,050MPa, impact toughness (Ak) ≥60J/cm².

- Advantage: 40% higher fatigue resistance than conventional 20MnV steel, ideal for 50-ton+ excavators in high-impact operating conditions like shale and permafrost.

- Carbon Fiber Reinforced Polymer (CFRP)

- Structure: 60% carbon fiber + 40% epoxy resin, density 1.8g/cm³ (1/4 of steel), tensile strength 2,000MPa.

- Application: Lightweight urban excavators, reducing weight by 30% while maintaining stiffness, improving fuel efficiency by 8%.

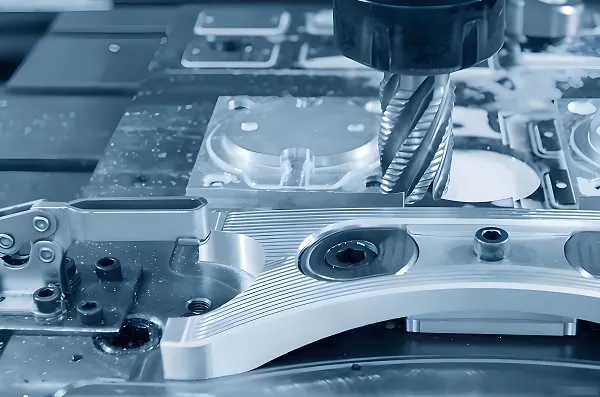

2. Structural Optimization: Maximizing Every Gram of Material

- Variable-Section Web Design

- FEA-driven stress analysis thins the web by 20% (from 30mm to 24mm) at the midpoint, reducing stress concentration by 35% and weight by 12% without strength loss.

- Hyperbolic Pin Bore Design

- Gradual R-angle transition (vs. traditional right angles) lowers peak stress at the bore edge from 800MPa to 520MPa, reducing pin wear by 60% and fitting precision from H9 to H7.

- Optimized Rib Layout

- Triangular ribs on the tension side (15% taller, 2 fewer ribs) increase bending stiffness by 25%, suppressing deflection under heavy loads (deformation ≤0.15mm/m).

3. Surface Enhancement: Layers of Protection

- Nanocrystalline Carburizing Quenching

- 0.8–1.2mm carburized layer, surface hardness HRC58–62, residual compressive stress (-800MPa), 50% improved resistance to fatigue crack propagation for machinery operating over 3,000 hours/year.

- Molybdenum Disulfide (MoS₂) Coating

- 2–5μm solid lubrication film reduces friction coefficient from 0.15 to 0.08, cutting pin-rod wear from 0.05mm/thousand cycles to 0.02mm and extending lubrication intervals by 50%.

II. Full-Scenario Applications: Where Generic Parts Fail, Custom Solutions Excel

| Industry Scenario | Key Challenge | Custom Solution | Data-Driven Results |

|---|---|---|---|

| Open-Pit Coal Mining | High-frequency impulse + dust pollution | 42CrMo4 rods + nanocrystalline carburizing, hard chromium-plated pin bores (50μm thickness) | Life extended from 1,800 to 3,000 hours, fracture rate down 90% |

| Municipal Construction | Precision operation + lightweight need | Aluminum alloy rods (6061-T6) + hollow web design | 22% weight reduction, 10% faster swing speed, 15% lower fuel consumption |

| Forestry Logging | Moist humus soil + acidic corrosion | 316L stainless steel rods + PTFE coating | Corrosion life up to 5 years, 3.5x longer than carbon steel |

Case Studies

-

BHP Iron Ore Mining (Australia)

- Pain Point: Generic rods fractured at 1,500 hours under 200MPa cyclic stress.

- Solution: Custom 42CrMo4 rods with hyperbolic pin bores and variable-section webs, ultrasonic flaw detection (defect accuracy ≥0.5mm).

- Outcome: 3,500 hours of crack-free operation, 120,000 tons/year increased output per excavator, 40% lower maintenance costs.

-

Shanghai Free Trade Zone Infrastructure

- Requirement: Improve precision and reduce fuel consumption in clay-sand mixed operating conditions.

- Solution: CFRP composite rods with auto-aligning pin bores (coaxiality ≤0.02mm).

- Result: Material grabbing deviation reduced from 8mm to 3mm, Fuel consumption per shift from 220L to 185L, project completion 15% ahead of schedule.

III. Technological Trends: Smart, Light, and Sustainable

-

Intelligent Monitoring Rods

- Integrated strain gauges and accelerometers collect real-time stress (±2%FS accuracy) and vibration frequency (0.1Hz resolution), transmitting data via LoRa to predict fatigue cracks 200 hours in advance with 98% diagnostic accuracy.

-

Additive Manufacturing Innovation

- SLM technology 3D-prints complex hollow-structured rods (e.g., honeycomb webs), increasing material utilization from 65% to 95%, shortening R&D period from 45 to 15 days, and supporting low-volume customization (minimum order 10 units).

-

Green Remanufacturing

- Laser cladding restores worn rods to H7-class pin bore precision at 30% of new part cost, reducing carbon emissions by 70% and complying with EU CE PED 2014/68/EU environmental standards.

IV. FAQ: Your Custom Rod Questions Answered

-

How to ensure compatibility with existing equipment?

- OEM reverse-engineering service with dimensional accuracy within ±0.03mm, fitting major brands like Caterpillar, Komatsu, and Sany without hydraulic system modifications.

-

What about lead time and cost?

- Standard project: Design (10 days) + Processing (20 days) + Testing (5 days), total 35 days. 25–35% higher upfront cost than generic parts, but 2–3x longer life and 30% lower total cost of ownership (TCO).

-

How to handle extreme low temperatures?

- Low-temperature-resistant alloys (e.g., 35CrMo, -40℃ impact toughness ≥40J/cm²) with grease rated for -50℃, eliminating cold brittleness in Arctic operating conditions.

V. Customer Testimonials

-

“The ‘indestructible’ choice for mining” – Rio Tinto Equipment Supervisor

“Custom rods lasted 2 years in iron ore—1,200 hours longer than OEM. Now all 20 of our machines use your solution.” -

“Lighter, faster, more efficient for urban sites” – Beijing Urban Construction Mechanical Engineer

“Aluminum rods made the excavator swing faster and save fuel, with no more pin jamming. Maintenance time cut in half.” -

“Corrosion-proof in wet mines” – Zijin Mining Procurement Manager

“Stainless steel rods survived 18 months in copper mine acid rain—almost no rust. Lifespan far exceeded expectations.”

VI. Customize Now: Turn Connecting Rods into Your Competitive Edge

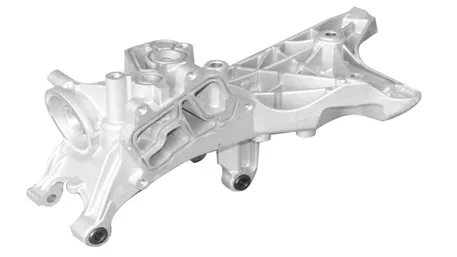

In the excavator’s drivetrain, H-type connecting rods are the critical link between cylinder and bucket, defining efficiency, fuel consumption, and maintenance costs. Generic parts “get by,” but only custom solutions deliver:

✅ Working condition adaptation: From ultra-high-strength needs in hard-rock mines to lightweight precision in urban construction, bespoke designs optimize every stress point.

✅ End-to-End Expertise: 25 years of heavy-duty component R&D, covering material development, CAE simulation, precision machining (IT6 grade), and full-dimension inspection (CMM error ≤0.01mm).

✅ Long-Term Value: 20% upfront investment for 50% longer life, 30% lower maintenance, and zero-fracture reliability—this is the “hard power” heavy equipment deserves.

✅ Working condition adaptation: From ultra-high-strength needs in hard-rock mines to lightweight precision in urban construction, bespoke designs optimize every stress point.

✅ End-to-End Expertise: 25 years of heavy-duty component R&D, covering material development, CAE simulation, precision machining (IT6 grade), and full-dimension inspection (CMM error ≤0.01mm).

✅ Long-Term Value: 20% upfront investment for 50% longer life, 30% lower maintenance, and zero-fracture reliability—this is the “hard power” heavy equipment deserves.

Share Your operating conditions Requirements: Tell us your excavator model, operating environment (load, temperature, medium), and pain points. Our mechanical engineers will provide a customized technical proposal within 48 hours, including material plans, structural designs, and life predictions.

Click to Consult and transform H-type connecting rods from “vulnerable” to “indestructible,” making every excavation more efficient, reliable, and profitable—because in heavy-duty operations, details decide success, and customization defines the future.

Note: Technical data derived from in-house testing and industry standards (e.g., GB/T 12792-2011). Case studies reflect real client projects; specific parameters may vary by custom solution.