In the field of precision manufacturing, custom CNC (Computer Numerical Control) hardware parts have become an indispensable part of many industries due to their high accuracy, high efficiency and diverse material options. Whether it’s automotive manufacturing, aerospace, medical devices or electronic communications, CNC hardware parts play a vital role. Below is a comprehensive introduction to custom CNC hardware parts.

1. CNC hardware parts production process

Demand analysis: firstly, customers need to provide detailed drawings of the parts, technical requirements and expected use, according to which engineers carry out feasibility analysis and design optimization.

Programming design: according to the requirements of the drawings, use CAD/CAM software to prepare machining programs, accurate calculation of tool paths and cutting parameters.

Material Preparation: Select hardware materials that meet the requirements, such as stainless steel, aluminum alloy, brass or special alloys, for cutting or forming pretreatment.

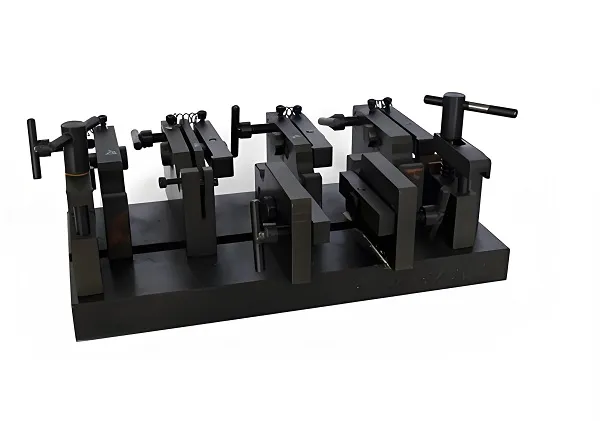

CNC machining: Fix the materials on CNC machine tools and carry out automatic machining according to the predetermined program, including milling, drilling, cutting and tapping.

Quality Inspection: Precision measuring tools are used to check the size, shape tolerance and surface quality of the parts to ensure compliance with standards.

Surface treatment: according to the demand for sandblasting, anodizing, plating and other surface treatment, to enhance the corrosion resistance and aesthetics of the parts.

Packing and shipping: Clean, rust-proof and pack the qualified parts properly, and arrange the logistics to ship to the customer’s designated place.

2. CNC hardware parts processing steps

Setting benchmarks: Set the machining benchmarks accurately on the workpiece to ensure the accuracy of subsequent machining.

Roughing: Remove most of the excess material and approach the final shape quickly.

Semi-finish machining: further trimming to improve the accuracy of the part.

Finishing: Achieve the final dimensions and surface roughness required by the drawing.

Special machining (if required): such as boring, engraving, tapping and other special treatments.

3. Customized CNC hardware parts service

Quick response: provide preliminary quotation and design proposal within 24 hours.

Personalized customization: adjust the design according to customer requirements to meet special needs.

One-stop service: full tracking service from design to production to after-sale.

Quality Assurance: Strict quality control system to ensure excellent quality of each batch of parts.

Sample production: provide small batch samples for trial production, for customer confirmation before mass production.

4. CNC hardware parts material introduction

Stainless steel: high corrosion resistance, suitable for harsh environments.

Characteristics: high temperature resistance, beautiful, easy to clean.

Characteristics: high strength, suitable for structural parts.

Aluminum alloy: light weight and high strength, good thermal and electrical conductivity.

Characteristics: easy to process, suitable for complex shapes.

Characteristics: corrosion resistance (after surface treatment), suitable for exterior parts.

Brass: good machinability and corrosion resistance.

Characteristics: beautiful, commonly used in decorative parts.

Characteristics: good electrical conductivity, suitable for electrical parts.

5. Characteristics of CNC hardware parts made of different materials

Stainless steel parts: products such as fasteners, valve body, data show that its hardness can reach HRC 30-40, corrosion resistance level up to SS304/316 standard, long service life.

Aluminum alloy parts: such as heat sinks, shells, with the advantage of lightweight, lower density than steel, high thermal conductivity, suitable for weight-sensitive applications.

Brass parts: such as decorations, plumbing fittings, due to its unique golden color and good ductility, it is commonly used in applications that require aesthetics and a certain degree of strength.

Customized CNC Hardware Parts Service FAQ

Q: What is the minimum order quantity for customized CNC hardware parts?

A: Usually the minimum order quantity depends on the complexity and size of the parts, usually ranging from 10-50 pieces, please contact our customer service for details.

Q: How long is the cycle time?

A: The processing cycle varies depending on the complexity and quantity of the parts, usually within 7-30 working days, urgent orders can be expedited.

Q: How do you guarantee the quality of the parts?

A: We have a strict quality control system, from the raw materials into the warehouse to the finished product factory, each process is strictly inspected to ensure that each product meets the customer’s requirements.

Q: Can you provide drawing modification and design service?

A: Yes, our team of professional engineers can provide drawing review, modification and customized design services.