In the world of automotive engineering, every component plays a critical role in delivering optimal performance. Among these, custom CNC machined automotive axle shafts stand out as the backbone of a vehicle’s drivetrain system. Whether you’re building a high-performance race car, upgrading an off-road vehicle, or creating a custom build, precision-engineered axle shafts are essential for transmitting power efficiently while withstanding extreme conditions.

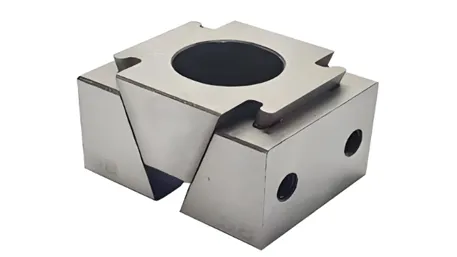

Precision-machined splined axle shaft ready for installation

What Are CNC Machined Automotive Axle Shafts?

CNC (Computer Numerical Control) machining has revolutionized the manufacturing of automotive axle shafts. This advanced process uses computer-controlled tools to shape metal components with unparalleled accuracy and consistency. Unlike traditional machining methods that rely heavily on manual operation, CNC machining ensures that every cut, drill, and turn is executed with exact precision.

The CNC Machining Process for Axle Shafts

The production of custom CNC machined axle shafts involves several key stages:

- Design Engineering: CAD (Computer-Aided Design) software creates detailed 3D models of the axle shaft based on specific vehicle requirements and performance goals.

- Material Selection: High-quality metals such as 40Cr, 42CrMo alloy steel, or SAE-4340 nickel chromoly are chosen for their strength and durability.

- Precision Machining: CNC lathes and milling machines shape the raw material into the desired form, creating splines, keyways, and other critical features with tolerances as tight as ±0.0004 inches.

- Heat Treatment: The axle shafts undergo specialized heat treatment processes to enhance strength, hardness, and resistance to wear.

- Surface Finishing: Protective coatings such as zinc plating, powder coating, or anodizing are applied to prevent corrosion and improve longevity.

Close-up view of precision machining on a CNC lathe

The Advantages of Custom CNC Machined Axle Shafts

When it comes to performance and reliability, custom CNC machined automotive axle shafts offer numerous benefits over standard off-the-shelf components:

Unmatched Precision and Consistency

CNC machining technology ensures that every axle shaft is manufactured to exact specifications. This precision guarantees:

- Perfect fitment with other drivetrain components

- Consistent performance across multiple units

- Reduced vibration and noise during operation

- Improved overall vehicle handling and safety

Superior Strength and Durability

Custom axle shafts are engineered to withstand the most demanding conditions:

- High-Torque Applications: Designed to handle increased power outputs from modified engines

- Extreme Terrain: Built for off-road vehicles navigating rough environments

- Racing Conditions: Engineered for the rigors of competitive motorsports

Tailored to Your Exact Requirements

One of the biggest advantages of custom CNC machining is the ability to create axle shafts that meet your specific needs:

- Custom lengths and diameters

- Specialized spline configurations

- Material selection based on application

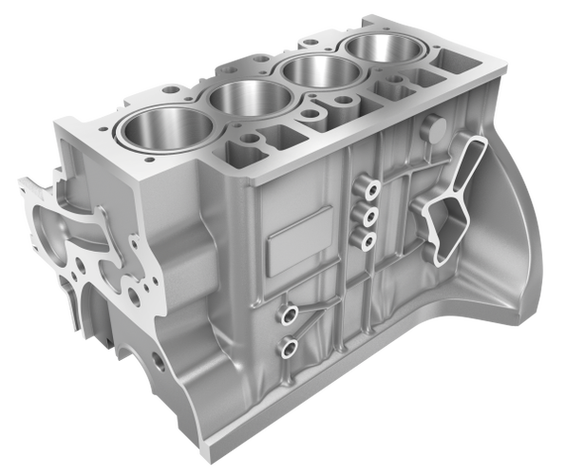

Complete drive shaft assemblies ready for installation

Applications: Where Custom CNC Axle Shafts Excel

Custom CNC machined automotive axle shafts are the preferred choice for a wide range of applications:

High-Performance Racing Vehicles

In the world of motorsports, every component must perform at its peak. Custom axle shafts provide:

- The strength needed for high-horsepower engines

- The precision required for tight tolerances in racing applications

- Weight optimization for improved performance

Off-Road and 4×4 Vehicles

Off-road enthusiasts demand components that can handle the toughest conditions:

- Increased ground clearance modifications

- Larger tire installations

- Extreme torque loads from four-wheel drive systems

Custom Vehicle Builds

For automotive enthusiasts creating one-of-a-kind vehicles:

- Vintage car restorations requiring exact reproductions

- Street rod projects with unique drivetrain configurations

- Show cars demanding perfect fit and finish

Commercial and Heavy-Duty Applications

Beyond passenger vehicles, custom axle shafts are essential for:

- Commercial trucks and fleet vehicles

The Customization Process: From Concept to Completion

At our manufacturing facility, we’ve streamlined the process of creating custom CNC machined automotive axle shafts to ensure quality and efficiency:

Step 1: Initial Consultation and Design

Our engineering team works closely with you to understand your specific requirements:

- Vehicle make, model, and year

- Performance goals and application

- Existing modifications and future plans

Step 2: Engineering and Prototyping

Using advanced CAD software, we create detailed designs and produce prototypes:

- 3D modeling and simulation

- FEA (Finite Element Analysis) for stress testing

- Prototype production for fitment verification

Step 3: Precision Manufacturing

Once the design is approved, we move to full production:

- CNC turning and milling operations

- Heat treatment and surface finishing

- Quality control inspections at every stage

Step 4: Quality Assurance and Testing

Every custom axle shaft undergoes rigorous testing:

- Dimensional accuracy verification

- Material strength testing

- Dynamic balancing for vibration reduction

Step 5: Delivery and Support

We ensure timely delivery and provide ongoing support:

- Secure packaging to prevent damage during shipping

- Installation guidance and technical support

- Warranty coverage for peace of mind

Material Selection Guide for Custom Axle Shafts

Choosing the right material is crucial for achieving optimal performance from your custom CNC machined axle shafts:

40Cr Alloy Steel

Best for: General performance applications, street use, and moderate racing

Advantages:

- Excellent balance of strength and ductility

- Easy to machine and heat treat

42CrMo Alloy Steel

Best for: High-performance street, racing, and heavy-duty applications

Advantages:

- Superior strength and toughness

- Excellent fatigue resistance

- Good corrosion resistance

- Ideal for high-torque environments

SAE-4340 Nickel Chromoly Steel

Best for: Extreme performance, racing, and off-road applications

Advantages:

- Exceptional strength-to-weight ratio

- Outstanding fatigue resistance

- Preferred material for professional racing teams

Aluminum Alloys (6061-T6, 7075-T6)

Best for: Weight reduction in performance applications

Advantages:

- Significant weight savings (30-40% compared to steel)

- Good corrosion resistance

- Excellent heat dissipation

Stainless Steel (304, 316)

Best for: Marine applications, corrosive environments

Advantages:

- Superior corrosion resistance

- Low maintenance requirements

Complete axle assembly showing various components

Customer Success Stories

Our commitment to quality and precision has earned us the trust of automotive enthusiasts and professionals worldwide:

Racing Team Championship Win

A professional racing team approached us needing custom axle shafts for their championship-winning car. We engineered lightweight 4340 chromoly shafts that reduced unsprung weight by 15% while increasing torque capacity by 25%. The team went on to win multiple races that season.

Off-Road Enthusiast’s Dream Build

An off-road enthusiast needed custom axle shafts for his heavily modified Jeep Wrangler. We created shafts with increased diameter and custom spline counts to handle 37-inch tires and a supercharged V8 engine. The vehicle now conquers the most challenging trails with ease.

Vintage Car Restoration Project

A classic car restorer required exact reproductions of rare axle shafts for a 1960s muscle car. Using reverse engineering techniques, we created precise replicas that matched the original specifications perfectly, allowing the restoration to maintain its authenticity.

Frequently Asked Questions About Custom CNC Machined Axle Shafts

How long does it take to produce custom CNC machined axle shafts?

The production timeline typically ranges from 2-4 weeks depending on complexity and order volume. Prototypes can often be completed in 1-2 weeks.

What information do I need to provide for a custom axle shaft quote?

To provide an accurate quote, we’ll need:

- Vehicle specifications (make, model, year)

- Dimensions (length, diameter, spline count)

Can you match existing axle shafts or create new designs?

Yes, we can both reverse engineer existing shafts and create entirely new designs based on your specifications. Our engineering team can work from drawings, samples, or even just measurements.

What quality standards do your custom axle shafts meet?

All our custom CNC machined axle shafts meet or exceed industry standards. We adhere to ISO 9001 quality management practices and perform rigorous testing to ensure every component meets our strict quality criteria.

Do you offer warranty coverage for custom axle shafts?

Yes, we stand behind our products with a comprehensive warranty. Warranty coverage varies based on application but typically ranges from 1-3 years for standard applications and includes replacement for defects in materials or workmanship.

Can custom axle shafts improve my vehicle’s performance?

Absolutely! Custom axle shafts can provide numerous performance benefits:

- Increased torque capacity

- Reduced weight for improved handling

- Better durability for extreme conditions

- Perfect fitment for custom applications

Why Choose Our Custom CNC Machined Axle Shafts?

When it comes to custom CNC machined automotive axle shafts, we stand out from the competition:

Unparalleled Expertise

With over 20 years of experience in precision machining, our team has the knowledge and skills to handle even the most complex projects.

State-of-the-Art Equipment

Our manufacturing facility is equipped with the latest CNC technology, allowing us to achieve tolerances as tight as ±0.0004 inches.

Quality Commitment

We maintain strict quality control throughout the manufacturing process, from material selection to final inspection.

Customer-Focused Approach

We work closely with each customer to understand their specific needs and provide personalized solutions that exceed expectations.

Competitive Pricing

Despite our commitment to quality, we offer competitive pricing for both small and large production runs.

Get Started with Your Custom CNC Machined Axle Shafts Today

Ready to take your vehicle’s performance to the next level with custom CNC machined automotive axle shafts? Contact our team of experts today to discuss your project requirements.

How to Begin:

- Request a Consultation: Our engineering team will work with you to understand your specific needs.

- Receive a Custom Quote: We’ll provide a detailed quote based on your requirements.

- Approve the Design: Review and approve the 3D design before production begins.

- Production and Testing: We’ll manufacture and test your custom axle shafts to ensure quality.

- Delivery: Your custom axle shafts will be delivered ready for installation.

Don’t settle for off-the-shelf components that don’t meet your exact needs. Invest in custom CNC machined automotive axle shafts and experience the difference precision engineering can make in your vehicle’s performance and reliability.

Contact us today to start your custom axle shaft project and discover why automotive enthusiasts and professionals trust us for their most demanding applications.

This article was written to provide valuable information about custom CNC machined automotive axle shafts. For more information or to request a quote, please contact our sales team.