In the exhaust system of automotive engines, the exhaust manifold, as a key component guiding the discharge of high-temperature exhaust gases, directly influences the engine’s power output, fuel economy, and exhaust emission performance. Traditional standardized exhaust manifolds are prone to issues such as thermal fatigue cracking, excessive exhaust backpressure, and vibration-induced noise under high-temperature, high-pressure, and high-flow-rate conditions. In contrast, customized CNC machined automotive exhaust manifolds achieve a leap from “basic exhaust function” to “performance optimization” through data-driven precise design and precision manufacturing. This article will analyze how to create high-temperature-resistant and low-resistance exhaust manifold solutions from the dimensions of customization value, core processes, and quality control.

1. Why Can’t Standardized Exhaust Manifolds Meet the Requirements of Modern Vehicles?

Q: What are the Core Advantages of Custom Automotive Exhaust Manifolds?

Standardized exhaust manifolds are mostly manufactured by casting followed by simple machining processes, with three significant drawbacks:

- Insufficient Thermal Management Performance: Traditional manifolds feature a uniform wall thickness design (commonly 3 – 5mm), failing to withstand local high temperatures (up to 900°C), which leads to concentrated thermal stress and makes them prone to cracking at welds or corners.

- Low Exhaust Efficiency: The lack of optimized layout of the manifold passages causes severe interference between the exhaust gases of each cylinder, resulting in excessively high exhaust backpressure (15 – 20% higher than the ideal value), reducing engine power output and fuel economy.

- Vibration and Noise Issues: Without optimizing the structure according to the engine’s vibration frequency (50 – 200Hz) and exhaust pulse characteristics, resonance is likely to occur, increasing in – vehicle noise by 5 – 8dB.

Custom automotive exhaust manifolds, on the other hand, focus on “precise exhaust gas ducting”:

- Deep Adaptation to Operating Conditions: Key parameters are customized according to engine models (gasoline/diesel/hybrid) and the number of cylinders (3 – 12):

-

- Exhaust manifolds for high-performance engines: Adopt unequal-length branch pipe designs to optimize the exhaust phase difference of each cylinder. The inner wall roughness of the branch pipes is controlled at Ra≤1.6μm, reducing exhaust resistance by 12% and increasing engine power by 8 – 10%.

-

- Exhaust manifolds for turbocharged engines: Strengthen the heat-resistant coating (thickness 0.2 – 0.3mm), enabling resistance to temperatures up to 1050°C. Meanwhile, topological optimization reduces weight by 18 – 25%.

- Data-Driven Design: Computational Fluid Dynamics (CFD) is used to simulate exhaust gas flow, precisely designing the manifold’s pipe diameter (tolerance ±0.05mm) and branch pipe angles (±0.5°). Finite Element Analysis (FEA) optimizes thermal stress distribution, ensuring that the stress values at key parts are below 70% of the material’s high-temperature yield strength.

2. How Do the Core Processes of Custom Exhaust Manifolds Achieve Performance Breakthroughs?

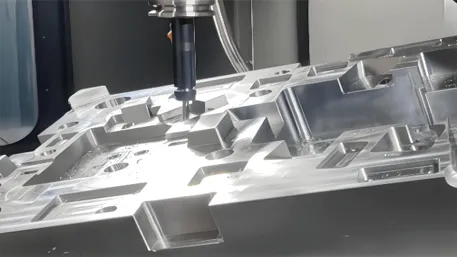

1. 5-Axis Machining and Integrated Laser Welding

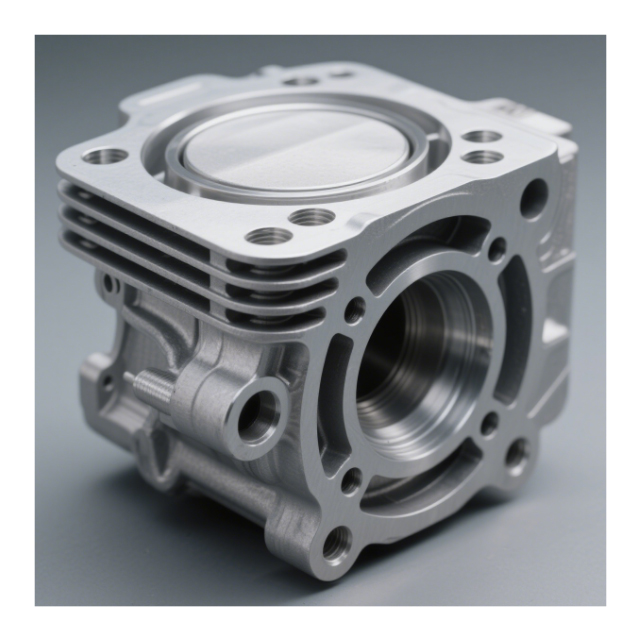

The complex curved surfaces, irregular branch pipes, and thin-walled structures (wall thickness 2 – 3mm) of automotive exhaust manifolds require 5-axis machining centers and laser welding equipment for high-precision manufacturing:

- High-Precision Milling: 5-axis machining is employed, and by rotating the A/B axes (±45°), the inner walls of the manifold are finely milled. The surface roughness is controlled below Ra1.6μm, ensuring smooth exhaust gas flow and reducing vortex generation.

- Laser Welding Forming: Fiber laser welding (power 3 – 5kW) is used to connect the components of the manifold. The weld width is 0.3 – 0.5mm, the penetration depth is 1 – 1.2mm, the welding deformation is <0.08mm, and the weld strength reaches over 92% of the base material, effectively enhancing overall sealing performance.

- Full-Process Integrated Machining: A zero-point positioning system (repeatability ≤0.003mm) completes milling, drilling, welding, and other processes in one clamping, avoiding form and position deviations caused by multi-step clamping (coaxiality errors in traditional processes can easily reach ±0.1mm).

2. Heat Treatment and Surface Strengthening Technologies

- Solution Aging Treatment: Solution treatment (heating to 1050 – 1100°C and holding for 2 – 3h) followed by aging treatment (700 – 750°C and holding for 8 – 10h) is carried out on heat-resistant alloy manifolds, improving the material’s high-temperature strength and fatigue resistance. The tensile strength is increased to 850 – 950MPa.

- Thermal Barrier Coating Spraying: Plasma spraying technology is used to coat the manifold surface with a ceramic thermal barrier coating (ZrO₂-based, thickness 0.2 – 0.4mm), enhancing the heat insulation effect by 30% and reducing the outer wall temperature of the manifold by 80 – 120°C to protect surrounding components.

- Shot Peening Strengthening: Automated shot peening equipment impacts the manifold surface with high-speed shots (diameter 0.2 – 0.6mm), forming a residual compressive stress layer of 0.1 – 0.3mm, increasing the thermal fatigue life by more than 40%.

3. End-to-End CNC Machining Data Closed-Loop

- Programming Phase: When generating tool paths with UG/CAM software, it simultaneously simulates the deformation of the manifold under high-temperature and high-pressure conditions, optimizing the machining allowance (reserved 0.3 – 0.5mm) to avoid workpiece deformation caused by cutting heat.

- Machining Execution: Real-time collection of over 30 parameters, including cutting force (set to a maximum of 200N for heat-resistant alloy machining), spindle vibration (threshold 0.02mm), and cutting temperature (automatic cooling when exceeding 600°C). In case of abnormalities, the feed rate is automatically adjusted, increasing tool life by 60%. The yield rate of manifold machining is increased from 80% to 97%.

- Inspection Phase: A Coordinate Measuring Machine (CMM) scans the key dimensions of the manifold (pipe diameter tolerance ±0.03mm, branch pipe angle ±0.3°), and industrial CT detects internal defects. The data is uploaded to the MES system in real-time, creating a traceable machining file.

3. Quality Control: Rigorous Verification from Material to Finished Product

1. Multi-Dimensional Performance Inspection System

- Strict Material Screening:

-

- Heat-Resistant Alloy Manifolds: Spectral analysis of chromium, nickel, and molybdenum content (e.g., for Inconel 625 material, Cr 20 – 23%, Ni 58 – 63%). Metallographic analysis of the grain size (≥Grade 5) ensures high-temperature stability.

-

- Cast Iron Manifolds: Ultrasonic flaw detection detects internal shrinkage porosity and air holes (blanks with defect diameters >0.5mm are rejected). Hardness testing (HB180 – 220) verifies wear resistance.

- Finished Product Functional Tests:

-

- High-Temperature Resistance Test: Withstand a temperature of 1000°C for 2 hours without deformation or cracks, and the dimensional change is <0.1%.

-

- Pressure Test: Apply 1.5 times the rated exhaust pressure (5 – 8bar) and maintain it for 10 minutes. There should be no leakage, and the residual deformation is <0.05mm.

-

- Fatigue Life Test: Simulate 1 million thermal cycles (temperature fluctuation 300 – 900°C), with no thermal fatigue cracks in key parts.

2. Intelligent Defect Prevention Technology

- First-Article Seven-Inspection System: Programmers, operators, quality inspectors, process engineers, equipment technicians, material inspectors, and measurement technicians jointly verify 25 key dimensions of the manifold, such as pipe diameter (±0.03mm) and branch pipe length (±0.05mm), intercepting millimeter-level deviations.

- AI Visual Full Inspection: Linear array cameras complete surface scanning in 0.8 seconds, accurately identifying defects such as cracks (length >0.5mm) and sand holes (diameter >0.3mm), with a miss rate of less than 0.002%, meeting the zero-defect acceptance criteria of OEMs.

4. How Does Small-Batch Customization Balance Efficiency and Cost?

Q: Does High-Precision Customization Mean High Costs?

Through three innovative processes, custom production efficiency has increased by 70%, and costs have decreased by 30%:

- Modular Process Library: Feature modules for manifold branch pipes, flanges, and connecting bends are established, reusing 90% of processing parameters for similar manifolds. Programming time is reduced from 15 hours to 4 hours.

- Automated Flexible Production: Truss robots, combined with quick-change fixtures (model change time <5 minutes), enable mixed production of multiple varieties in small batches (80 – 400 pieces). The intelligent warehousing system automatically matches tools, increasing equipment utilization to 92%.

- Tool Life Prediction: For cemented carbide tools used in heat-resistant alloy machining, tool life is predicted through cutting force spectrum analysis (e.g., 120 pieces per cutting edge). The system automatically triggers tool changes to avoid dimensional deviations caused by tool wear.

5. Core Considerations for Selecting Custom Automotive Exhaust Manifolds

- Data Transparency: High-quality suppliers should provide complete documents, including CFD flow field analysis reports, FEA thermal stress analysis reports, CNC machining parameter logs, and full-dimension inspection reports, to ensure that the performance of each manifold can be quantitatively verified.

- Composite Technical Capabilities: Required capabilities include 5-axis machining, laser welding, heat treatment quenching and tempering, surface coating treatment, non-destructive testing, etc., to meet the requirements of different materials (heat-resistant alloys/cast iron/stainless steel) and operating conditions.

- Response Speed and Adaptability: Sample delivery within ≤22 days after drawing confirmation supports synchronous development with OEMs. The ability to design manifolds specifically for new energy vehicles is required (such as adapting to the special exhaust requirements of hybrid engines).

Conclusion

The value of custom CNC machined automotive exhaust manifolds lies in defining the “precision of exhaust gas ducting” with data and ensuring “adaptability to high-temperature conditions” through advanced processes. With the automotive industry trending towards high efficiency, environmental protection, and low noise, customized solutions featuring “data-driven structural optimization + precision manufacturing processes” are becoming crucial for automakers to enhance engine performance and reduce emissions. From the powerful power release of traditional fuel vehicles to the quiet and efficient operation of new energy vehicles, custom exhaust manifolds will support “long-lasting reliability” with “micron-level precision”, making every exhaust gas discharge efficient and orderly.

(Contact us now to obtain an exclusive custom automotive exhaust manifold solution and a free flow field performance analysis)