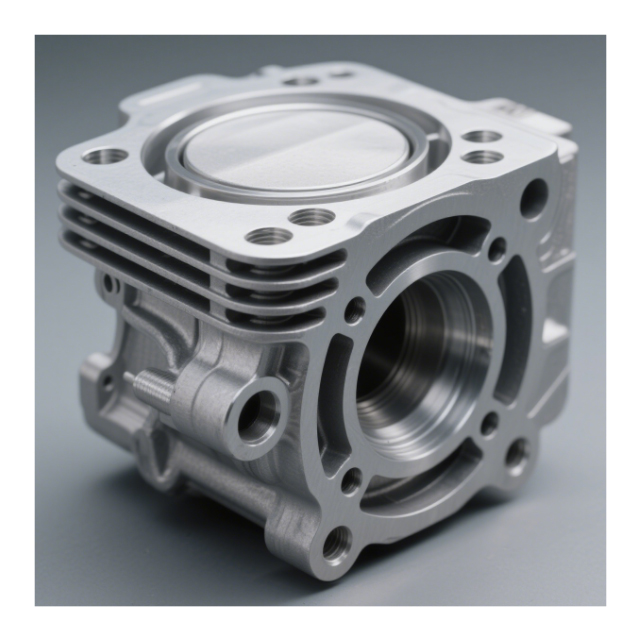

In modern automotive systems, impellers serve as critical components in engines (turbochargers) and electric drives (oil/water pumps), directly influencing fluid dynamics, energy conversion efficiency, and overall system reliability. Traditional standardized impellers often struggle with issues like insufficient flow precision, excessive noise, or early fatigue failure under variable loads. Customized CNC machined automotive impellers, however, leverage data-driven precision manufacturing to achieve a leap from “general-purpose” to “high-performance,” becoming key to unlocking core system capabilities. This article dissects how to create “aerodynamic-optimized” impeller solutions from the dimensions of customization value, core processes, and quality control.

1. Why Standard Impellers Fail to Meet High-Efficiency Demands

Q: What Sets Custom Impellers Apart from Standard Ones?

Standard impellers, typically produced via casting or generic CNC machining, have three inherent limitations:

- Flow Field Mismatch: Rough blade profiles (surface roughness Ra≥3.2μm) and generic curvature design lead to flow separation, increasing pressure loss by 15% and reducing turbocharger efficiency by 8–10%.

- Tolerance Slackness: Traditional machining tolerances (blade thickness ±0.1mm, outlet angle ±1°) fail to meet the precise requirements of new energy vehicles, where electric pump impellers demand blade angle tolerances of ±0.5° and thickness control within ±0.05mm.

- Material Insufficiency: Common aluminum alloys (such as ADC12) used in standard impellers lack high-temperature strength, leading to deformation at 300℃ (common in turbocharger environments), whereas custom impellers use heat-resistant alloys like 6061-T6 or titanium aluminide.

Custom impellers focus on “data-defined fluid dynamics”:

- Deep Operating Condition Adaptation: Tailored to application scenarios (turbocharger/supercharger/e-pump), key parameters are optimized:

-

- Turbocharger impellers: Blade tip clearance controlled at 0.05–0.1mm (to reduce leakage), with variable pitch design (pitch angle deviation ≤0.3°) to handle high-speed rotation (100,000–300,000rpm).

-

- E-pump impellers: Narrow blade spacing (2–5mm) and smooth transition radii (R≥2mm) to minimize cavitation, with surface roughness Ra≤1.6μm to improve pump efficiency by 5–8%.

- Data-Driven Aerodynamic Design: CFD (Computational Fluid Dynamics) simulation optimizes blade curvature (NACA airfoil profile deviation ≤0.02mm) and shroud shape, reducing turbulent flow and noise by 10–15dB compared to standard designs.

2. Core Processes for Achieving Aerodynamic Precision

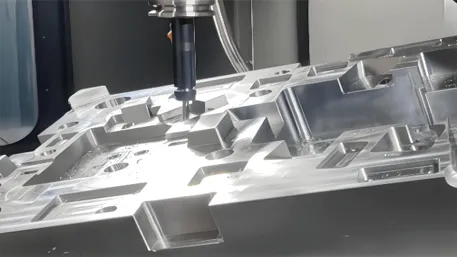

1. 5-Axis Precision Machining: Complex Surfaces in One Setup

Impellers’ hyperbolic blades, twisted channels, and thin-walled structures (blade thickness 1–3mm) require 5-axis CNC machines with advanced control systems:

- Trochoidal Milling Strategy: Reduces blade cutting load by 30% through continuous tool engagement, avoiding full immersion that causes vibration. Surface roughness of blade surfaces is controlled at Ra0.8μm, 50% smoother than 3-axis machining.

- RTCP Real-Time Tool Compensation: Maintains constant tool orientation relative to blade surfaces via real-time kinematic compensation, ensuring uniform cutting depth (0.2–0.5mm) and minimizing form errors (blade profile tolerance ±0.01mm).

- Vacuum Chuck Fixturing: For aluminum impellers (weight 20–50g), vacuum chucks (clamping force 50–100N) reduce deformation to <0.02mm, solving the thin-wall vibration problem common in traditional mechanical clamping.

2. End-to-End Data Closed-Loop Control

From design to delivery, every step is governed by precision data:

- Programming Phase: PowerMill software generates tool paths while simulating stress distribution under maximum load (turbocharger impeller centrifugal force up to 50,000N), optimizing fillet radii at blade roots (R≥1.5mm) to prevent fatigue cracks.

- Machining Execution: Real-time monitoring of 40+ parameters, including spindle vibration (threshold 0.03mm), cutting torque (titanium impeller limit 20N·m), and tool temperature (over 150℃ triggers automatic cooling). This reduces tool breakage by 60% and boosts machining stability.

-

- 3D Scan Comparison: Using a laser scanner (resolution 5μm), blade surface deviation is measured against the CAD model, with a pass standard of ±0.02mm.

-

- Dynamic Balancing Test: For high-speed impellers, residual unbalance is controlled below 5g·mm, ensuring vibration amplitude ≤0.05mm at rated speed.

3. Quality Control: Full-Chain Verification from Material to Dynamic Performance

1. Multi-Dimensional Performance Inspection System

- Material-Level Screening:

-

- Titanium Impellers: X-ray flaw detection eliminates internal micro-cracks (size >0.1mm), and tensile testing ensures yield strength ≥800MPa at 300℃.

-

- CFRP Impellers: Ultrasonic testing verifies fiber layup consistency (void content ≤1%), critical for lightweight electric drive applications (weight reduction 40% vs. aluminum).

- Finished Product Testing:

-

- Flow Characteristic Test: In a hydraulic test bench, flow rate deviation is controlled within ±1.5% (vs. ±3% for standard impellers), ensuring stable fluid supply under fluctuating loads.

-

- Fatigue Life Test: Simulates 10 million cycles of variable-speed operation (speed range 20%–120% of rated speed), with blade tip wear <0.01mm to meet 8-year service life requirements.

2. Intelligent Defect Prevention Technology

- First-Article Ten-Inspections System: A cross-functional team verifies 30+ key dimensions, including blade outlet angle (±0.5°), tip clearance (±0.01mm), and shroud runout (≤0.03mm), intercepting potential deviations at the source.

- AI Visual Full Inspection: High-resolution line-scan cameras (pixel accuracy 10μm) inspect each impeller in 1 second, detecting surface defects (scratches >0.1mm, burrs >0.05mm) with a miss rate <0.005%, meeting automotive-grade zero-defect standards.

4. How Small-Batch Customization Balances Precision and Efficiency

Q: Can High Precision Coexist with Small-Batch Production?

Three innovative processes achieve a 40% efficiency boost and 25% cost reduction:

- Parametric Process Library: Predefined modules for blade roughing, finishing, and hub machining reuse 80% of parameters for similar impellers, cutting programming time from 10 to 4 hours.

- Automated Flexible Production: A robotic arm with a quick-change adapter (tool change time <15 seconds) enables mixed production of turbocharger and e-pump impellers on the same 5-axis machine, increasing equipment utilization to 90%.

- Tool Life Prediction System: Machine learning models analyze sensor data to predict carbide end-mill life (e.g., 80 pieces/edge for aluminum), with an accuracy of ±5%, reducing unplanned downtime by 35%.

5. Core Considerations for Choosing Custom Impellers

- Data Traceability: Suppliers should provide CFD analysis reports, CNC machining logs, and 3D deviation maps, ensuring every impeller’s aerodynamic performance is quantifiable and traceable.

- Composite Technical Capabilities: Required expertise includes 5-axis precision machining, material heat treatment (e.g., T6 aging for aluminum), and dynamic balancing (G2.5 grade), especially for high-speed turbocharger impellers.

- Response Speed & Adaptability: Sample delivery within 20 days after drawing confirmation supports OEM rapid prototyping; capability to handle diverse materials (aluminum, titanium, CFRP) meets the lightweight needs of new energy vehicles.

Conclusion

The value of custom CNC machined automotive impellers lies in defining “aerodynamic precision” with data and achieving “full-load condition adaptation” with advanced processes. As engines pursue higher thermal efficiency and electric drives aim for higher power density, customized solutions with “data-driven aerodynamic design + precision 5-axis machining” are becoming key for automakers to break through system efficiency bottlenecks. From turbocharger upgrades in traditional ICE vehicles to e-drive innovations in new energy cars, custom impellers will drive “system-level performance” with “micron-level precision,” making every fluid conversion a core of high-efficiency power.

(Contact us today to get your exclusive impeller customization solution and free CFD flow analysis)