Welcome to the world of custom CNC machined parts. In this age of innovation and challenge, every detail is critical. We understand that in the world of precision manufacturing, custom CNC parts are key to enhancing equipment performance and optimizing production processes. Therefore, we are committed to providing superior custom CNC machined parts services to meet your unique manufacturing needs.

1. Personalized Design

Drawing customization: Accept the drawings or detailed specifications provided by customers for precise interpretation and optimization.

Demand Communication: Communicate with customers to understand the specific use, working environment and performance requirements of the parts to ensure that the design meets the actual needs.

Innovative design: Combined with the latest technology trends, provide innovative design suggestions to enhance the performance and service life of parts.

2. Advanced Processing Technology

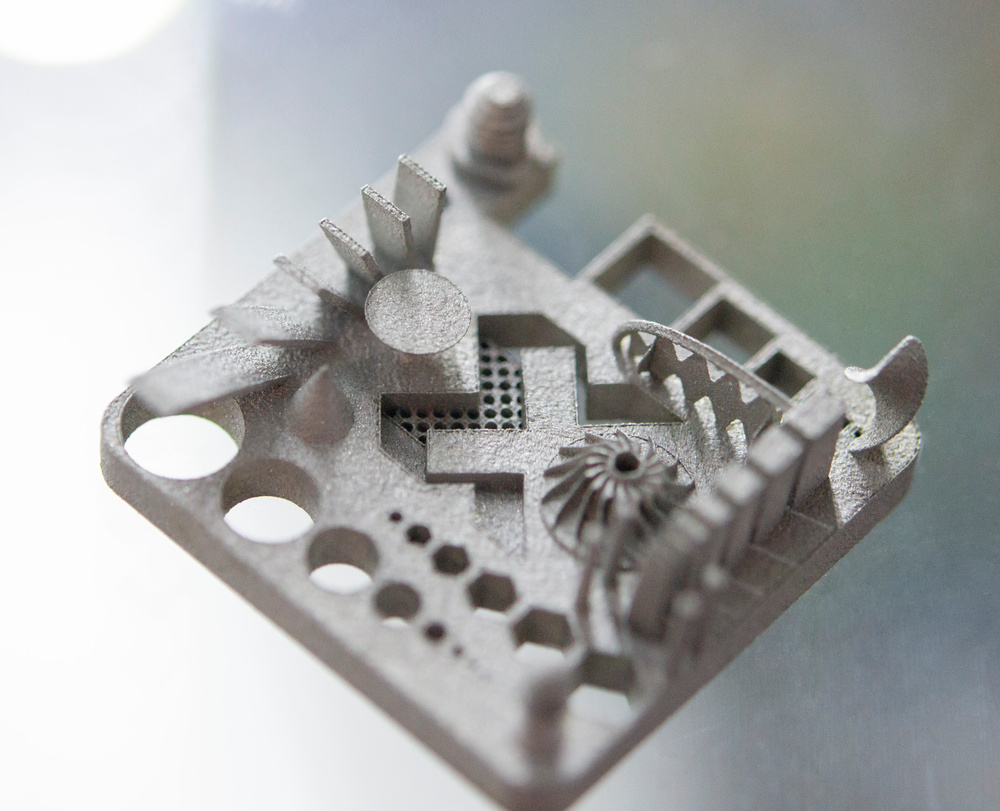

High-precision CNC machining: Adopting the world’s leading CNC machine tools to ensure that the machining accuracy of parts reaches the micron level.

Multi-axis machining capability: supports one-time machining of complex structural parts, reducing assembly errors and improving production efficiency.

Surface treatment technology: provide a variety of surface treatment options such as sandblasting, polishing, anodizing, etc. to enhance the durability and aesthetics of the parts.

3. Wide range of material options

Metal materials: stainless steel, aluminum alloy, titanium alloy, brass, etc. to meet different strength and corrosion resistance needs.

Non-metallic materials: plastics, nylon, POM, etc., suitable for lightweighting, insulation or applications in specific chemical environments.

Special materials: customized processing of ceramics, graphite and other high-performance materials according to customer needs.

4. Strict quality control

Whole process monitoring: from raw material purchasing to finished products leaving the factory, every step is strictly inspected.

Non-destructive testing: Adopt ultrasonic, X-ray and other non-destructive testing technologies to ensure that there are no defects inside the parts.

Performance Test: Functional tests are conducted according to the use of the parts to ensure that the design requirements are met.

5. Rapid Response and Shipment

Flexible production: Adjust the production plan according to the order quantity to respond quickly to customer needs.

Standard shipment cycle: In general, the processing cycle for standard parts is 7-14 days, and urgent orders can be prioritized.

Global Delivery: Cooperate with many international logistics companies to provide fast and safe delivery service worldwide.

Frequently Asked Questions

Q: I don’t have a drawing, can you design it for me?

A: Of course you can. Our team of engineers will provide one-stop service from conceptual design to detailed drawings according to your specific needs.

Q: What types of parts can you machine?

A: We specialize in machining metal and non-metal parts of various complex structures, including but not limited to shafts, gears, boxes, brackets and so on.

Q: How do you ensure the machining accuracy of parts?

A: We use high-precision CNC machine tools combined with advanced measurement and inspection technologies to ensure that the machining accuracy of our parts meets or exceeds industry standards.

Q: How long is your delivery lead time?

A: The lead time for standard parts is 7-14 days, depending on the complexity and quantity of the parts. Rush orders will be prioritized to the best of our ability.

Q: Can you provide samples for testing?

A: Yes, we can provide sample testing service upon customer’s request to ensure the performance of the parts in real applications.

Thank you for choosing our custom CNC machined parts service! We promise to meet your every customized demand with the most professional attitude, the most advanced technology and the best service. We look forward to working with you to create a better future!