- Achieving tight tolerances of ±0.02 mm

- Preventing warping in machined parts

- Ensuring consistent quality across small to medium batches

- Maintaining cost control throughout the production cycle

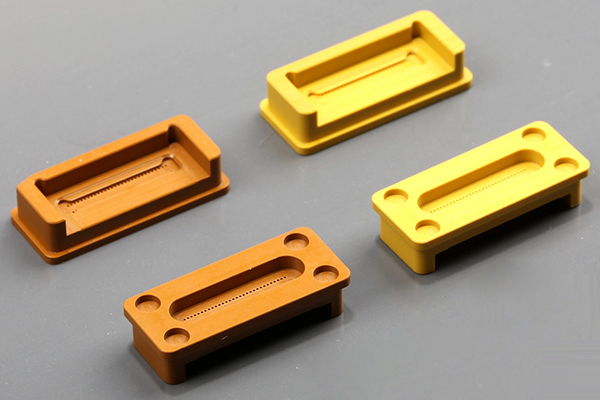

What Are CNC Machined Plastic Parts?

Key Characteristics of CNC Plastic Machining:

- Material Removal Process: Uses cutting tools to shape plastic blocks

- High Precision: Achieves tight tolerances not possible with additive methods

- Complex Geometry: Handles intricate designs with multi-axis capabilities

- Superior Surface Finish: Produces smooth surfaces with minimal post-processing

- PEEK: Requires controlled cutting speeds to prevent thermal degradation

- Delrin: Demands specific tooling to achieve optimal surface quality

- Nylon: Needs proper fixturing to prevent vibration during machining

Why Choose CNC Machining for Plastic Parts?

Manufacturing Method Comparison

|

Manufacturing Method

|

Tolerance Range

|

Surface Finish (Ra)

|

Setup Cost

|

Unit Cost (100 pieces)

|

Lead Time

|

|

CNC Machining

|

±0.005-0.05 mm

|

0.8-3.2 μm

|

Low

|

$15-50

|

3-7 days

|

|

3D Printing

|

±0.1-0.2 mm

|

6.3-12.5 μm

|

Very Low

|

$5-25

|

1-3 days

|

|

Injection Molding

|

±0.02-0.1 mm

|

1.6-6.3 μm

|

Very High

|

$0.5-5

|

4-8 weeks

|

Key Advantages of CNC Machining:

- Achieves tolerances as tight as ±0.005 mm

- Surpasses most additive manufacturing methods

- Essential for components requiring precise fits and functional performance

- Produces smoother surfaces with Ra values as low as 0.8 μm

- Eliminates layer lines common in 3D printed parts

- Reduces need for secondary finishing operations

- No upfront mold costs associated with injection molding

- Economically viable for production runs from 1 to 10,000 pieces

- Allows for rapid prototyping and on-demand production

- Handles common plastics like ABS and nylon

- Processes high-performance polymers such as PEEK and PTFE

- Accommodates materials with different mechanical properties

Common Plastic Materials for CNC Machining

Material Properties Comparison

|

Material

|

Tensile Strength (MPa)

|

Temperature Resistance (°C)

|

Machinability

|

Common Applications

|

|

ABS

|

40-50

|

70-90

|

Excellent

|

Housings, enclosures

|

|

Delrin

|

60-70

|

120-150

|

Excellent

|

Gears, pulleys

|

|

Nylon

|

65-80

|

120-180

|

Good

|

Bushings, bearings

|

|

PC

|

60-75

|

130-140

|

Good

|

Sight glasses, lenses

|

|

PMMA

|

50-70

|

80-100

|

Excellent

|

Display cases

|

|

PEEK

|

90-100

|

260-280

|

Fair

|

Aerospace, medical

|

Detailed Material Information:

- Properties: Good impact resistance, excellent machinability

- Advantages: Dimensional stability, consistent performance

- Applications: Housings, enclosures, consumer electronics components

- Properties: Excellent dimensional stability, low friction

- Advantages: Reliable mechanical performance, wear resistance

- Applications: Gears, pulleys, precision automotive components

- Properties: High strength-to-weight ratio, good chemical resistance

- Advantages: Durable, self-lubricating properties

- Applications: Bushings, bearings, structural industrial components

- Properties: Transparency, high impact resistance

- Advantages: Combination of clarity and strength

- Applications: Sight glasses, light covers, medical device components

- Properties: Superior optical clarity, scratch resistance

- Advantages: Excellent aesthetic qualities

- Applications: Display cases, lenses, light guides

- Properties: High heat resistance, biocompatibility

- Advantages: Performance in extreme environments

- Applications: Aerospace components, medical implants

Key Capabilities in Custom CNC Plastic Machining

Advanced Machining Technologies

- 5-Axis CNC Machines: Handle complex geometries with precision

- High-Speed Machining: Reduces cycle times while maintaining quality

- Multi-Spindle Systems: Increases production efficiency for complex parts

Quality Control Measures

- Coordinate Measuring Machine (CMM): Ensures dimensional accuracy

- Laser Scanning: Verifies complex surfaces and contours

- Statistical Process Control (SPC): Maintains consistent quality

Production Capabilities:

- Tolerance Control: From ±0.005 mm to ±0.05 mm

- Part Size Range: From micro-components to large parts (up to 1200×800×600 mm)

- Production Volume: 1 piece to 100,000+ pieces

- Lead Time: 24-hour prototype service available

Surface Finishing Options:

- As-Machined: Standard machining finish (Ra 1.6-3.2 μm)

- Polished: Smooth surface finish (Ra 0.8-1.6 μm)

- Textured: Custom surface patterns and textures

- Coated: Protective and decorative coatings

Industries Using Machined Plastic Parts

Automotive Industry

- Transmission Components: Precision gears and bushings

- Engine Parts: Sensor mounts and connectors

- Interior Systems: Custom brackets and housings

- Exterior Components: Aerodynamic parts and trim

Medical Industry

- Surgical Instruments: Precision cutting tools and handles

- Diagnostic Equipment: Enclosures and mounting hardware

- Implants: Biocompatible components (PEEK, titanium)

- Disposables: Single-use medical devices

Electronics Industry

- Consumer Electronics: Phone cases, tablet housings

- Industrial Electronics: Control panel enclosures

- Telecommunications: Fiber optic components

- Semiconductor: Wafer handling equipment parts

Aerospace Industry

- Aircraft Interiors: Seat components, tray tables

- Avionics: Electronic enclosures with flame retardant materials

- Engine Components: Heat-resistant parts (PEEK, PEI)

- Structural Parts: Lightweight brackets and supports

How to Work With a CNC Machining Supplier

Preparation Guidelines

- Provide detailed 3D models (STEP, IGES, or STL files)

- Include 2D drawings with GD&T annotations

- Specify material requirements and certifications

- Define surface finish requirements (Ra values)

- Base tolerances on functional requirements, not defaults

- Consider material properties when specifying tolerances

- Use standard tolerance grades (ISO 286) when possible

- Identify critical dimensions that affect functionality

- Define inspection criteria and acceptance standards

- Specify testing requirements (if any)

- Request documentation (material certificates, inspection reports)

- Consider PPAP requirements for automotive applications

Project Management Process

- Initial Consultation

-

- Technical review of designs

-

- Material selection recommendations

-

- Manufacturing feasibility assessment

-

- Cost estimation and lead time proposal

- Prototype Development

-

- Rapid prototyping service

-

- Design validation testing

-

- Iteration and optimization

-

- Final design approval

- Production Planning

-

- Manufacturing process development

-

- Tooling and fixture design

-

- Quality control plan implementation

-

- Production scheduling

- Manufacturing Execution

-

- Precision machining operations

-

- In-process quality inspections

-

- Surface finishing and treatment

-

- Final inspection and testing

- Delivery and Support

-

- Packaging and shipping coordination

-

- Installation support (if required)

-

- After-sales service and technical support

-

- Continuous improvement initiatives

Why Choose Our CNC Plastic Machining Service

Company Strengths

- 26 years of manufacturing experience

- National high-tech enterprise certification

- ISO 9001 quality management system

- SGS, RoHS, CE international certifications

- 100+ advanced CNC machines

- 5-axis machining centers for complex parts

- ±0.005 mm precision tolerance control

- CMM inspection for dimensional accuracy

- 24/7 manufacturing operations

- On-time delivery rate of 98%

- Production range: 1 piece to 100,000+ pieces

- Rapid prototyping service (24-48 hours)

- Serving customers in 50+ countries

- Multilingual technical support

- International shipping and logistics

- Local representatives in key markets

Quality Assurance

- Incoming material inspection

- In-process quality checks

- Final inspection before shipment

- Statistical process control

- Material certificates and test reports

- Inspection reports and measurement data

- Batch traceability for all components

- Compliance with industry standards

Case Studies

Case Study 1: Automotive Transmission Component

- European automotive Tier 1 supplier

- Developing new transmission system for electric vehicles

- Required precision plastic gears with tight tolerances

- Achieve ±0.01 mm tolerance on gear tooth profiles

- Ensure consistent quality across 50,000-piece annual production

- Meet strict durability and performance requirements

- Material: Delrin 500P (high-performance acetal copolymer)

- Process: 5-axis CNC machining with specialized gear cutting tools

- Quality Control: CMM inspection of every 100th part

- Production: Automated manufacturing cells with SPC monitoring

- Successfully maintained ±0.008 mm tolerance (exceeding requirement)

- Zero defects in initial production run

- Improved transmission efficiency by 3%

- Secured long-term supply contract for 5 years

Case Study 2: Medical Device Component

- US-based medical device manufacturer

- Developing minimally invasive surgical instrument

- Required biocompatible plastic components

- Material must meet USP Class VI biocompatibility standards

- Complex geometry requiring multi-axis machining

- Strict cleanliness requirements for medical applications

- Material: PEEK (biocompatible, sterilizable polymer)

- Process: Dedicated cleanroom machining environment

- Quality Control: 100% inspection with laser scanning

- Documentation: Full PPAP Level 3 documentation package

- Components passed all biocompatibility tests

- Met FDA regulatory requirements for medical devices

- Enabled successful product launch within timeline

- Established ongoing partnership for multiple product lines

Conclusion

- Superior precision (±0.005 mm tolerance capability)

- Material versatility (from common plastics to high-performance polymers)

- Production flexibility (1 piece to 100,000+ pieces)

- Cost-effectiveness (no mold costs for small to medium batches)