Table of Contents

- Company Profile

- Titanium Material Properties and Advantages

- Service Capabilities Overview

- Technical Specifications and Precision

- Machining Process

- Quality Control System

- Application Fields

- Service Advantages

- Customer Cases

- Contact Us

Company Profile

- Technical Strength: Team of senior engineers with extensive experience and advanced CNC machining equipment

- Quality Assurance: Strict quality management system with 99.8% product qualification rate

- Timely Delivery: Efficient production management to ensure on-time delivery

- Comprehensive Service: Professional pre-sales consultation and after-sales service system

- Equipment Quantity: Hundreds of high-precision CNC machining centers

- Processing Capacity: From small-batch prototyping to large-scale production

- Quality Certifications: ISO 9001, ISO 13485 (Medical Devices), AS9100 (Aerospace)

Titanium Material Properties and Advantages

Material Properties

|

Property

|

Parameter

|

Advantage

|

|

Density

|

4.51 g/cm³

|

Approximately 60% of steel, offering significant weight reduction

|

|

Tensile Strength

|

686-1176 MPa

|

High strength meeting structural component requirements

|

|

Specific Strength

|

Extremely high

|

Highest strength-to-weight ratio among all metals

|

|

Corrosion Resistance

|

Excellent

|

Superior performance in seawater and acid-base environments

|

|

Biocompatibility

|

Excellent

|

Good compatibility with human tissue, no rejection reaction

|

|

Operating Temperature

|

-253℃ ~ 600℃

|

Wide temperature range applicability

|

|

Hardness

|

32-38 HRC

|

Excellent wear resistance

|

Main Titanium Alloy Types

- Composition: 99.2% pure titanium

- Characteristics: Excellent corrosion resistance and weldability

- Applications: Chemical equipment, medical devices, marine components

- Composition: Titanium-6% aluminum-4% vanadium

- Characteristics: High strength with excellent comprehensive performance

- Applications: Aerospace components, medical implants, high-performance parts

- Composition: Extra Low Interstitial version of Ti-6Al-4V

- Characteristics: Enhanced biocompatibility and improved toughness

- Applications: Medical implants, surgical instruments

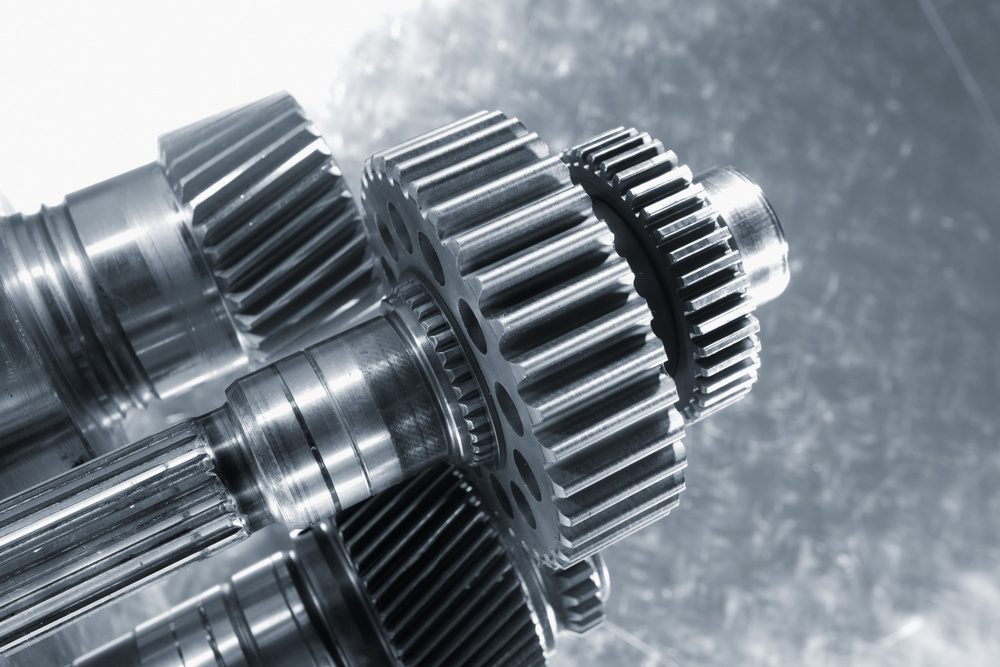

Service Capabilities Overview

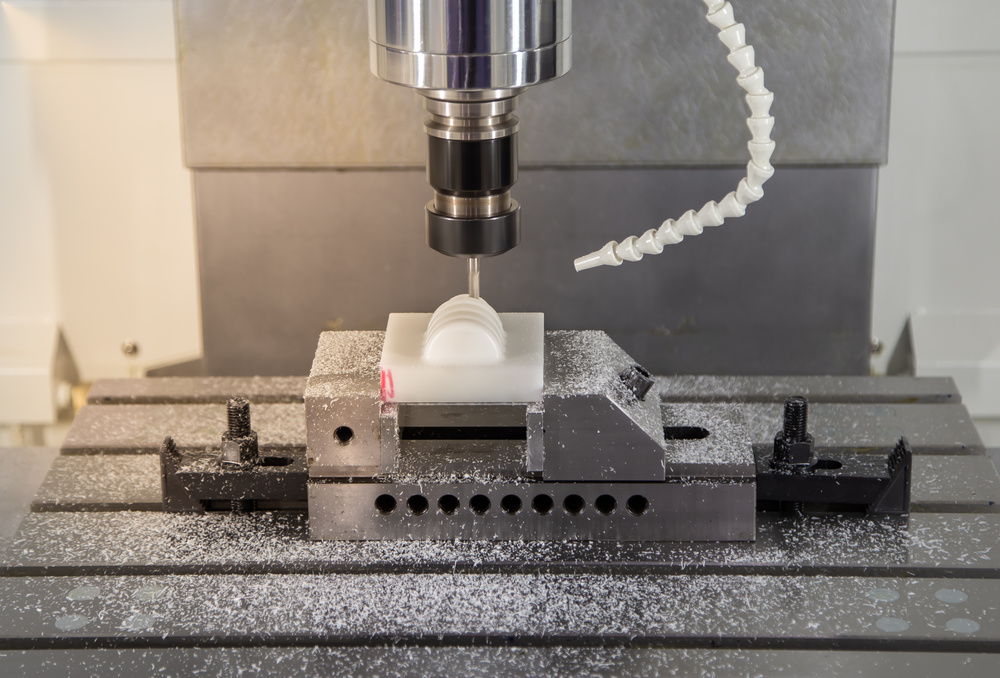

Machining Equipment

- Working Range: X: 1500mm, Y: 800mm, Z: 600mm

- Positioning Accuracy: ±0.003mm

- Repeatability: ±0.002mm

- Application: Planar and simple surface machining

- Working Range: X: 1200mm, Y: 600mm, Z: 500mm, A: 360°

- Positioning Accuracy: ±0.003mm

- Application: Complex surfaces and rotationally symmetric parts

- Working Range: X: 1000mm, Y: 600mm, Z: 500mm, A: ±120°, C: 360°

- Positioning Accuracy: ±0.002mm

- Application: Complex 3D structures and aerospace components

Machining Processes

- Face milling, end milling, contour milling

- Groove machining, hole machining, thread machining

- High-speed milling, trochoidal milling

- External turning, face turning

- Thread turning, groove turning

- Complex rotating component machining

- EDM (Electrical Discharge Machining)

- Deep hole drilling

- Precision grinding

Technical Specifications and Precision

Precision Capabilities

|

Machining Type

|

Dimensional Accuracy

|

Geometric Tolerance

|

Surface Roughness

|

|

3-axis Milling

|

±0.005mm

|

±0.003mm

|

Ra 0.8-3.2μm

|

|

4-axis Milling

|

±0.005mm

|

±0.003mm

|

Ra 0.8-3.2μm

|

|

5-axis Milling

|

±0.003mm

|

±0.002mm

|

Ra 0.4-1.6μm

|

|

CNC Turning

|

±0.002mm

|

±0.001mm

|

Ra 0.2-1.6μm

|

Material Processing Capabilities

|

Material

|

Cutting Speed

|

Feed Rate

|

Depth of Cut

|

|

Grade 2

|

50-150 m/min

|

0.1-0.3 mm/rev

|

0.5-2.0 mm

|

|

Grade 5

|

30-100 m/min

|

0.05-0.2 mm/rev

|

0.3-1.5 mm

|

|

Grade 23

|

40-120 m/min

|

0.08-0.25 mm/rev

|

0.4-1.8 mm

|

Special Processing Capabilities

- Thin-wall Machining: Minimum wall thickness 0.5mm

- Deep Cavity Machining: Aspect ratio up to 10:1

- Micro-hole Drilling: Minimum hole diameter 0.5mm

- Complex Surfaces: Support for free-form surface machining

Machining Process

1. Requirement Analysis and Technical Evaluation

- Detailed understanding of customer requirements and technical specifications

- Comprehensive analysis of design drawings or 3D models

- Provision of professional process recommendations

- Technical feasibility analysis

- Cost estimation and competitive quotation

- Delivery timeline assessment

- Development of detailed machining plans

- Selection of appropriate equipment and cutting tools

- Determination of optimal machining sequence and parameters

2. Programming and Tool Preparation

- Utilizing professional software including Mastercam and UG

- Generation of optimized machining programs

- Virtual simulation and verification

- Selection of tools specifically designed for titanium alloy machining

- Preparation of tool length and radius compensation data

- Implementation of tool wear monitoring systems

3. Trial Machining and First Article Inspection

- Precision workpiece clamping and positioning

- Tool installation and alignment

- Accurate coordinate system establishment

- Conducting trial cutting operations

- Precise measurement of key dimensions

- Confirmation of compliance with drawing requirements

- Comprehensive dimensional inspection

- Surface quality examination

- Customer approval confirmation (when required)

4. Batch Production and Process Monitoring

- Strict adherence to established process documentation

- Real-time monitoring of machining processes

- Regular quality sampling to ensure stability

- 100% inspection of critical processes

- Dimensional stability monitoring

- Prompt handling of any abnormal situations

5. Post-processing and Product Delivery

- Professional deburring and cleaning

- Optional surface treatments as specified

- Final quality inspection

- Professional packaging with protective measures

- Detailed quality inspection reports

- On-time delivery to customer specifications

Quality Control System

Quality Management System

- ISO 9001: Quality Management System Certification

- ISO 13485: Medical Device Quality Management System

- AS9100: Aerospace Quality Management System

- FDA Registration: Medical Device Product Registration

Testing Equipment

- Coordinate Measuring Machine: Accuracy ±0.001mm

- Profile Projector: Accuracy ±0.002mm

- Surface Roughness Tester: Measurement range Ra 0.025-12.5μm

- Universal Tool Microscope: Accuracy ±0.001mm

- Spectrometer: Material composition analysis

- Hardness Tester: Rockwell and Vickers hardness testing

- Metallurgical Microscope: Microstructure analysis

- Tensile Testing Machine: Mechanical property evaluation

Quality Control Process

- Raw material certification verification

- Dimensional and visual inspection

- Required physical and chemical property testing

- First article inspection confirmation

- Process patrol inspection and sampling

- Critical process monitoring

- Comprehensive dimensional inspection

- Surface quality verification

- Performance testing when required

- Final inspection confirmation

- Packaging integrity verification

- Quality documentation preparation

Application Fields

Aerospace Industry

- Landing Gear Components: Meeting high strength and lightweight requirements

- Fuselage Frames: Providing corrosion resistance and fatigue performance

- Engine Components: Ensuring high-temperature stability

- Rocket Engine Casings: High-pressure vessel applications

- Satellite Structural Components: Lightweight with corrosion resistance

- Missile Components: High precision and reliability

Medical Device Industry

- Artificial Joints: Hip and knee replacement systems

- Bone Plates and Screws: Fracture fixation devices

- Spinal Implants: Spinal correction and fusion systems

- Dental Implants: Excellent osseointegration with bone tissue

- Denture Frameworks: Lightweight and comfortable solutions

- Surgical Tools: High hardness and corrosion resistance

- Medical Device Components: Precision and reliability

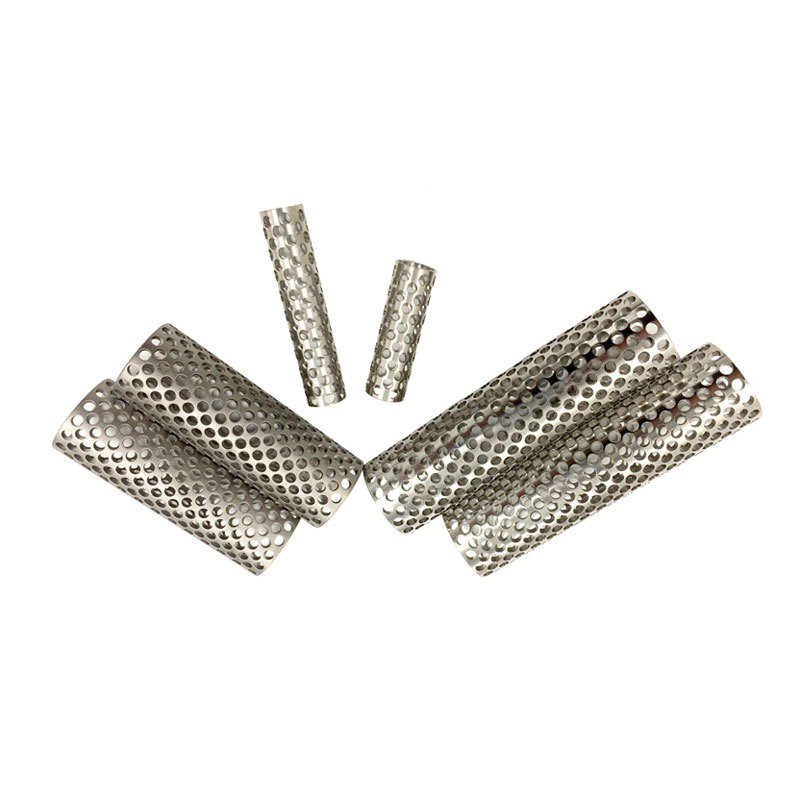

Industrial Applications

- Reactors: Designed for corrosive environment applications

- Heat Exchangers: Efficient heat transfer with corrosion resistance

- Piping Systems: Ensuring long-term reliability

- Seawater Treatment Equipment: Resistance to seawater corrosion

- Marine Components: Lightweight with corrosion resistance

- Offshore Platforms: Adaptability to harsh environments

- Wind Power Equipment: Lightweight with weather resistance

- Solar Energy Equipment: Precision components

- Energy Storage Systems: Meeting high-performance requirements

Service Advantages

Technical Advantages

- Team of senior engineers with over 10 years of average experience

- Specialized technical expertise in titanium alloy machining

- Continuous technical innovation and process optimization

- Imported high-precision CNC machining centers

- Complete testing equipment and quality control systems

- Automated production lines enhancing efficiency

- Machining parameters optimized for titanium alloy characteristics

- Advanced cooling and lubrication technologies

- Comprehensive tool life management and cost control

Service Advantages

- Flexible customized solutions

- Rapid response to customer requirements

- Professional technical consultation and support

- Rigorous quality management system

- Comprehensive testing and verification procedures

- Complete after-sales service and technical support

- Efficient production planning and scheduling

- Strict delivery time management

- Emergency response capabilities for rapid delivery

Cost Advantages

- Reduced unit costs through mass production capabilities

- Enhanced production efficiency with advanced equipment

- Optimized supply chain management

- Reduced manufacturing costs through process optimization

- Extended tool life minimizing consumption

- Labor cost reduction through automated production

Customer Cases

Case 1: Aerospace Engine Components

- Customer: Leading aircraft engine manufacturer

- Product: Compressor blades and casings

- Material: Ti-6Al-4V (Grade 5)

- Quantity: High-volume batch production

- Complex aerodynamic shape design

- Strict dimensional accuracy requirements (±0.005mm)

- Surface roughness specification Ra 0.8μm

- Stringent quality certification requirements

- Utilization of 5-axis CNC machining centers

- Implementation of high-speed milling technology

- Establishment of comprehensive quality control protocols

- Preparation of complete quality certification documentation

- Achieved product qualification rate of 99.8%

- Reduced delivery cycle by 20%

- Garnered high recognition from the customer

- Established long-term cooperative partnership

Case 2: Medical Implants

- Customer: International medical device manufacturer

- Product: Artificial hip joint components

- Material: Ti-6Al-4V ELI (Grade 23)

- Requirements: ISO 13485 certification compliance

- Complex anatomical design

- Stringent biocompatibility requirements

- Specialized surface treatment specifications

- Comprehensive traceability requirements

- 100% material certification verification

- Detailed inspection records for each manufacturing process

- Comprehensive testing of final products

- Complete quality documentation package

Case 3: Marine Engineering Components

- Customer: Marine engineering equipment manufacturer

- Product: Underwater connectors

- Material: Ti Grade 2

- Environment: Seawater corrosion environment

- Excellent seawater corrosion resistance

- High strength and reliability

- Extended service life

- Ease of maintenance

Contact Us

Contact Information

Quick Quotation

- Detailed part drawings or 3D models

- Material specifications and heat treatment requirements

- Accuracy and surface roughness requirements

- Quantity and delivery time requirements

- Special process or testing requirements

- Receive customer requirements and technical drawings

- Conduct technical evaluation and process analysis

- Perform cost calculation and prepare quotation

- Provide detailed quotation documentation

- Conduct technical communication and program confirmation

Quality Commitment

- Product Qualification Rate: ≥ 99.8%

- On-time Delivery Rate: ≥ 98%

- Customer Satisfaction Rate: ≥ 95%

- Quality Complaint Response: Within 24 hours