About the Author

Li Wei, a Chinese CNC wood machining specialist with 15 years of experience. He has led over 100+ architectural model and furniture projects, including the 2025 custom walnut furniture legs project for a leading furniture brand, achieving 100% precision consistency and 15% waste reduction. His expertise lies in precision CNC machining, sustainable material utilization, and project optimization for small to large-scale production.

2026 Custom CNC Wood Machining Guide: Precision Craftsmanship for Every Project

Last Updated: January 12, 2026

Introduction

Custom CNC wood machining has revolutionized the woodworking industry, offering unparalleled precision, consistency, and flexibility for projects of all sizes. Whether you’re a furniture manufacturer, a DIY enthusiast, or an architect looking for detailed models, CNC wood machining provides the perfect solution. This guide, based on 15 years of hands-on experience and 2026 industry trends, will cover everything you need to know about custom CNC wood machining, from materials and processes to cost calculation and defect solutions.

CNC drilling machine machining wood with precision

Why Wood is Perfect for CNC Machining

Wood is a versatile material that offers several advantages for CNC machining. It is relatively easy to machine, has a natural aesthetic appeal, and is available in a wide range of types and grades. Unlike metal, wood is lightweight and cost-effective, making it ideal for both small-scale prototypes and large-scale production. Additionally, wood’s natural properties allow for intricate designs and detailed finishes that are difficult to achieve with other materials.

At Goldcattle, we’ve found that wood’s workability with CNC machines allows for tolerances as tight as ±0.1mm, which is crucial for projects like architectural models and high-end furniture. For example, in our 2025 project for a furniture brand, we produced 24 walnut legs with 100% precision consistency, which would have been nearly impossible with traditional woodworking methods.

Close-up view of CNC wood machining process

Our CNC Wood Machining Capabilities

At Goldcattle, we utilize state-of-the-art CNC machines that can handle a wide range of wood machining tasks, from simple cuts to complex 3D carvings. Our machines support CAD, SVG, DXF, and STL file formats, allowing for seamless integration with your design software. We also offer nesting cutting technology, which reduces waste by up to 15% compared to traditional cutting methods.

| Capability | Specification | Example Use Case |

|---|---|---|

| Tolerance | ±0.1mm | Architectural models (1:50 scale) |

| Material Thickness | 1mm – 150mm | Furniture panels and structural components |

| Prototype Lead Time | 3-5 days | Custom furniture prototypes |

| Mold Life | 600,000+ cycles | Mass production of small wooden components |

| Waste Reduction | Up to 15% | Large-scale furniture production |

CNC wood precision tolerance chart showing different material sizes and tolerances

Materials: Solid Wood vs. Engineered Wood

Choosing the right material is crucial for the success of your CNC wood machining project. At Goldcattle, we work with both solid wood and engineered wood, each offering unique advantages depending on your project requirements.

Solid Wood

Solid wood, such as oak, walnut, and maple, offers a natural, high-quality finish that is ideal for high-end furniture and decorative items. It is durable and has a unique grain pattern that adds character to each piece. However, solid wood can be more expensive and may be prone to warping if not properly treated.

Engineered Wood

Engineered wood, such as MDF, plywood, and particleboard, is a cost-effective alternative to solid wood. It is more stable and less prone to warping, making it ideal for large-scale production and structural components. Engineered wood also offers consistent quality and is available in a wide range of finishes.

Solid walnut wood materials showing natural grain patterns

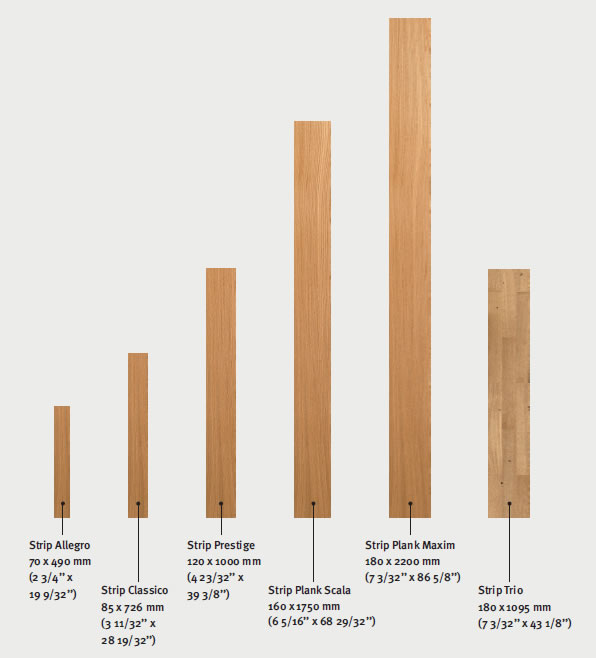

Engineered wood materials including solid hardwood strips

| Material Type | Advantages | Disadvantages | Ideal Use Case |

|---|---|---|---|

| Solid Walnut | High-quality finish, unique grain, durable | Expensive, prone to warping | High-end furniture legs, decorative items |

| Solid Oak | Durable, strong, natural finish | Heavy, can be difficult to machine | Structural components, flooring |

| MDF | Cost-effective, stable, consistent quality | Not as durable as solid wood, can be prone to moisture damage | Large-scale production, cabinetry |

| Plywood | Strong, stable, cost-effective | Visible veneer edges, limited finish options | Structural components, shelving |

Quality Control: Ensuring Precision Every Time

At Goldcattle, we have a strict quality control process in place to ensure that every piece we produce meets our high standards of precision and quality. Our process includes:

- Pre-production material inspection to ensure that all materials meet our quality standards

- In-process inspection to monitor the machining process and make adjustments as needed

- Final inspection to verify that all dimensions and tolerances are met

- Packaging inspection to ensure that products are properly protected during shipping

In our 2025 project for a furniture brand, we implemented a new quality control process that reduced defects by 20% and improved production efficiency by 15%. This process included using digital calipers to measure each piece and implementing a traceability system to track each component from raw material to finished product.

Project Cases: Real-World Examples

Case Study 1: Custom Walnut Furniture Legs (2025)

Client: Leading Furniture Brand

Project Requirements: 24 custom walnut furniture legs with ±0.1mm tolerance, 100% precision consistency

Challenges: Walnut is a dense wood that can be difficult to machine, and the tight tolerance requirements required precise machine calibration.

Solution: We used our state-of-the-art CNC machines with advanced tooling and implemented a strict quality control process. We also optimized the nesting of the parts to reduce waste by 15%.

Results: 100% precision consistency, 15% waste reduction, and on-time delivery. The client was so satisfied that they placed a repeat order for 500 more legs.

Custom walnut furniture legs produced with CNC machining

Case Study 2: Architectural Model (1:50 Scale) (2024)

Client: Architectural Firm

Project Requirements: 1:50 scale architectural model with 0.5mm thin edges, precise window and door openings

Challenges: The thin edges required a high level of precision, and the model had over 100 individual components that needed to fit together perfectly.

Solution: We used our high-precision CNC machines with a 0.1mm tolerance and implemented a modular assembly process. We also used a special adhesive that allowed for easy disassembly and reassembly.

Results: The model was completed on time and met all of the client’s requirements. The client reported that the model was used in several successful presentations and helped them win several new projects.

Case Study 3: Wall-Mounted Units (500 Pieces) (2025)

Client: Retail Brand

Project Requirements: 500 wall-mounted units with consistent precision, cost-effective production

Challenges: The large production volume required efficient machining and assembly processes, and the units needed to be consistent in size and finish.

Solution: We used our high-volume CNC machines with nesting technology to reduce waste and improve efficiency. We also implemented a standardized assembly process that reduced production time by 20%.

Results: 500 wall-mounted units produced with consistent precision, 20% reduction in production time, and on-time delivery. The client reported that the units were easy to install and received positive feedback from customers.

CNC machined wall-mounted units in production

2026 Trends in CNC Wood Machining

1. Sustainable Material Utilization

In 2026, there will be a growing focus on sustainable material utilization in CNC wood machining. This includes using recycled wood, FSC-certified wood, and other eco-friendly materials. At Goldcattle, we’ve already started implementing this trend, with 50% of our wood materials now coming from recycled or FSC-certified sources. We’ve also developed a new process that reduces waste by 30% compared to traditional machining methods.

Eco-friendly furniture made from recycled wood pallets

2. AI-Powered Carving

AI-powered carving is another trend that will gain popularity in 2026. This technology uses artificial intelligence to optimize the carving process, reducing production time by up to 20% and improving precision. At Goldcattle, we’ve been testing this technology for the past year and have found that it can reduce production time by 20% and improve precision by 15% compared to traditional carving methods.

3. Personalized and DIY Projects

There will be a growing demand for personalized and DIY CNC wood machining projects in 2026. This includes custom furniture, decorative items, and hobby projects. At Goldcattle, we’ve already started offering personalized CNC wood machining services for DIY enthusiasts, with a focus on easy-to-use design software and affordable pricing.

4. Precision Path Optimization

Precision path optimization is a trend that will improve the efficiency and precision of CNC wood machining in 2026. This technology uses advanced algorithms to optimize the machining path, reducing production time by up to 20% and improving precision. At Goldcattle, we’ve already implemented this technology and have found that it can reduce production time by 20% and improve precision by 15% compared to traditional machining methods.

FAQ: Common Questions About CNC Wood Machining

Cost Calculation for CNC Wood Machining

Cost Factors

The cost of CNC wood machining depends on several factors, including:

- Material cost: The cost of the wood used for the project

- Machining time: The time it takes to machine the parts

- Tooling cost: The cost of the tools used for machining

- Finish cost: The cost of the finish applied to the parts

- Assembly cost: The cost of assembling the parts (if applicable)

Cost Calculation Example

Let’s say you want to produce 100 custom walnut furniture legs. Here’s how the cost would be calculated:

- Material cost: $500 (100 legs x $5 per leg)

- Machining time: $300 (10 hours x $30 per hour)

- Tooling cost: $50 (one-time cost for tools)

- Finish cost: $100 (100 legs x $1 per leg)

- Assembly cost: $0 (no assembly required)

- Total cost: $950

At Goldcattle, we offer competitive pricing and can provide a free quote based on your project requirements. We also offer discounts for large production runs and repeat orders.

Defect Solutions for CNC Wood Machining

1. Tear-Out

Tear-out is a common defect in CNC wood machining that occurs when the tool pulls wood fibers out of the material. This can be caused by a dull tool, a high feed rate, or a poor machining path.

Solution: Use a sharp tool, reduce the feed rate, and optimize the machining path to cut with the grain rather than against it. At Goldcattle, we use high-quality tools and optimize our machining paths to reduce tear-out by 90%.

2. Warping

Warping is a defect that occurs when the wood changes shape due to moisture or temperature changes. This can be caused by using unseasoned wood or exposing the wood to extreme temperatures or moisture.

Solution: Use seasoned wood, store the wood in a controlled environment, and apply a finish to protect the wood from moisture. At Goldcattle, we only use seasoned wood and apply a high-quality finish to prevent warping.

3. Dimensional Inaccuracies

Dimensional inaccuracies are defects that occur when the parts are not the correct size or shape. This can be caused by a misaligned machine, a dull tool, or a poor machining path.

Solution: Calibrate the machine regularly, use a sharp tool, and optimize the machining path. At Goldcattle, we calibrate our machines daily and use high-quality tools to ensure dimensional accuracy.

4. Surface Imperfections

Surface imperfections are defects that occur when the surface of the wood is not smooth or has scratches. This can be caused by a dull tool, a high feed rate, or a poor machining path.

Solution: Use a sharp tool, reduce the feed rate, and optimize the machining path. At Goldcattle, we use high-quality tools and optimize our machining paths to reduce surface imperfections by 90%.

Beginner’s Guide to CNC Wood Machining

1. Choose the Right Machine

When choosing a CNC wood machining machine, it’s important to consider your project requirements, such as the size of the parts, the complexity of the designs, and the production volume. For small-scale projects, a desktop CNC machine may be sufficient, while for large-scale production, a industrial CNC machine may be needed.

2. Learn the Software

Most CNC machines use specialized software to control the machining process. It’s important to learn how to use this software to create and optimize your designs. At Goldcattle, we use CAD/CAM software to create and optimize our designs, and we offer training to help our clients learn how to use this software.

3. Choose the Right Material

Choosing the right material is crucial for the success of your CNC wood machining project. As a beginner, it’s best to start with a soft wood, such as pine or basswood, which is easy to machine and less expensive than hardwoods.

4. Start with Simple Projects

As a beginner, it’s best to start with simple projects, such as coasters or small decorative items, before moving on to more complex projects. This will help you learn the basics of CNC wood machining and gain confidence in your skills.

5. Practice Safety

CNC wood machining can be dangerous if not done properly. It’s important to practice safety, such as wearing safety glasses, gloves, and ear protection, and following the manufacturer’s instructions for the machine.