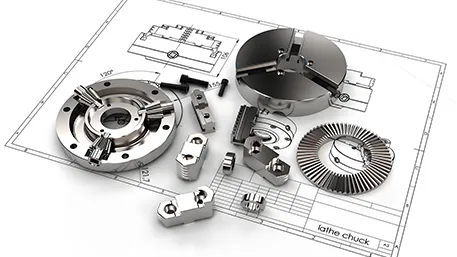

In the modern industrial manufacturing system, mechanical parts, as the basic units of equipment operation, their precision, performance, and adaptability directly determine the efficiency, stability, and lifespan of the entire system. With the development of the industry towards high – end and intelligent directions, CNC (Computer Numerical Control) technology, with its outstanding precision machining capabilities, has become the core technical support for customizing mechanical parts. This article will systematically analyze the technical logic and engineering value of custom CNC mechanical parts from dimensions such as technical principles, materials engineering, process optimization, quality control, and industry applications.

I. Core Advantages of CNC Technology in Customizing Mechanical Parts

CNC technology provides three core technical supports for the processing of mechanical parts through digital control and servo – drive systems:

-

Sub – micron – level Precision Assurance

The positioning accuracy of CNC machine tools can reach ±0.001mm, the repeat positioning accuracy is ±0.005mm, and the surface roughness Ra≤0.4μm. For example, when processing precision gears, the tooth profile error can be controlled within ±5μm, ensuring the low – noise and high – reliability of the transmission system. -

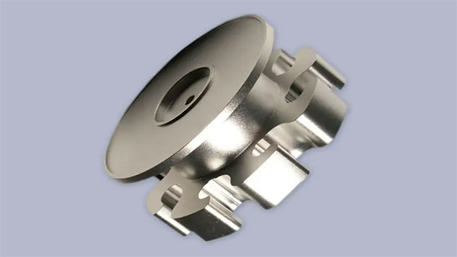

Full – dimensional Machining Ability for Complex Structures

Five – axis CNC equipment can achieve the processing of spatial curved surfaces, thin – wall structures (wall thickness ≤ 0.1mm), and micro – features (such as micro – holes with a diameter of 0.1mm) that are difficult to complete with traditional processes. For example, the three – dimensional curved surface of an aero – engine blade can be processed in one – step through five – axis milling, avoiding the accumulation of multi – process errors. -

High Compatibility of Materials and Processes

CNC technology is compatible with various materials such as alloy steels (such as 42CrMo), tool steels (such as H13), stainless steels (316L), and aluminum alloys (7075). According to the characteristics of different materials, cutting parameters can be optimized: when processing high – strength steels, using TiAlN – coated tools in combination with high – pressure internal cooling technology can extend the tool life by 3 times; when processing aluminum alloys, through high – speed cutting (HSC) technology, the material removal rate can be increased by 40%, while reducing thermal deformation.

II. Materials Engineering and Selection Strategies for Custom Mechanical Parts

Material selection is a crucial link in customizing mechanical parts and needs to be scientifically matched according to working conditions:

-

Design Oriented by Mechanical Properties

- High – load Scenarios: Select 42CrMo alloy steel (tensile strength ≥ 1080MPa, yield strength ≥ 930MPa), which is suitable for heavy – load gears, drive shafts, and other components.

- Wear – resistance Requirements: Use H13 tool steel (hardness HRC48 – 52) after quenching and tempering treatment, and the surface wear – resistance is increased by 5 times, which is suitable for mold cores and wear – resistant bushings.

-

Optimization of Environmental Adaptability

- Corrosive Environments: 316L stainless steel (PREN value ≥ 25) is used for chemical machinery parts, which can withstand the corrosion of media such as hydrochloric acid and brine, with a service life of more than 15 years.

- High – temperature Working Conditions: Select Inconel 718 superalloy, which can maintain high strength (tensile strength ≥ 1290MPa) at 650℃, and is suitable for aero – engine parts.

-

Balance between Cost and Performance

- Economical Solutions: Q235 carbon steel after surface quenching treatment, with a hardness of HRC40 – 45, and the cost is 60% lower than that of alloy steel, is suitable for ordinary mechanical structural parts.

- High – end Applications: Although the cost of titanium alloy (TC4) parts is relatively high, lightweight design (density 4.5g/cm³) can reduce the weight of components by 40%, while maintaining a tensile strength ≥ 895MPa, which is suitable for aerospace precision components.

III. Innovation and Optimization of CNC Machining Processes

In response to the diverse needs of mechanical parts, CNC machining processes achieve a double breakthrough in efficiency and quality through the following technological innovations:

-

Co – optimization of Tools and Paths

Using solid carbide tools (such as micro – diameter milling cutters with a diameter of 0.3mm) in combination with spiral interpolation paths, micro – holes with a depth – to – diameter ratio of 15:1 can be processed, with a dimensional accuracy of ±0.003mm.

For the problem of easy hardening during stainless – steel processing, applying high – pressure internal cooling technology and CBN tools can reduce the cutting temperature by 40% and extend the tool life by 2 times. -

Large – scale Application of High – speed Cutting (HSC) Technology

When processing aluminum – alloy parts, the spindle speed can reach 25000r/min, the feed rate is 6000mm/min, the material removal rate is increased by 50%, and at the same time, the surface roughness Ra≤0.8μm, meeting the processing requirements of precision housing – type parts. -

Five – axis Composite Machining Technology

Completing multi – surface processing in one clamping, such as the hole system and curved surface of complex valve bodies, the processing efficiency is increased by 70%, and the position accuracy reaches ±0.008mm, avoiding multiple – clamping errors.

IV. Quality Control System for Custom Mechanical Parts

To ensure that products meet industry standards and working – condition requirements, custom CNC mechanical parts need to go through a strict quality control process:

-

Dimensional and Geometric Tolerance Detection

Using a coordinate measuring machine (CMM) for full – size scanning, the tolerance of key dimensions (such as the diameter of shaft – type parts) is controlled within ±0.003mm.

Geometric tolerance detection: roundness error ≤ 0.002mm, parallelism ≤ 0.005mm/m, ensuring the assembly accuracy of parts. -

Verification of Material and Mechanical Properties

Spectral analysis to confirm the material composition, for example, the chromium content of 42CrMo alloy steel should be ≥ 0.9 – 1.2%, and the molybdenum content should be ≥ 0.15 – 0.25%.

Tensile tests, impact tests, and hardness tests (such as Brinell hardness HB) to ensure that the mechanical properties meet standards such as GB/T 3077. -

Surface Quality and Function Detection

Using a roughness tester to detect the Ra value of the surface, and for precision parts, it needs to reach Ra≤0.2μm.

Nondestructive testing: X – ray or ultrasonic testing for internal defects to ensure the reliability of safety – critical components (such as pressure vessel parts).

V. Industry Application Practices of Custom CNC Mechanical Parts

-

Aerospace Field

Custom – made titanium – alloy (TC4) blades are processed by five – axis CNC milling, with a profile error ≤ 0.02mm and fatigue strength ≥ 450MPa, meeting the high – speed rotation and high – temperature working – condition requirements of engines.

Aluminum – alloy (7075 – T6) frame parts are processed by high – speed cutting, reducing the weight by 35%, while the tensile strength ≥ 572MPa, ensuring the structural stability of spacecraft. -

Energy and Heavy Machinery

42CrMo alloy – steel gears are processed by CNC hobbing and shaving, with a tooth profile accuracy reaching ISO 5, and the transmission efficiency is increased by 12%, which is suitable for the transmission system of wind turbines.

Stainless – steel (316L) valve parts are precision – turned, with the roughness of the sealing surface Ra≤0.4μm, and the pressure – bearing capacity reaches 100MPa, meeting the harsh working conditions of the petrochemical industry. -

Precision Instrument Manufacturing

Custom – made H13 tool – steel cores are processed by CNC electrical – discharge machining (EDM), with a surface roughness Ra≤0.1μm and a service life of more than 500,000 times, which is suitable for high – end injection molds.

Aluminum – alloy (6061 – T6) optical platform parts are ground by CNC, with a flatness ≤ 0.005mm/m, providing stable support for precision optical equipment.

VI. Technological Trends and Industry Outlook

-

Upgrade of the Intelligent Processing System

The deep integration of AI algorithms and CNC systems can achieve real – time optimization of processing parameters. For example, by using machine learning to predict tool wear and dynamically adjust the feed rate, the processing efficiency can be increased by more than 25%. -

Application of Digital Twin Technology

Virtual simulation platforms pre – rehearse the processing process, discovering process defects in advance, shortening the new product development cycle by 40% and reducing trial – and – error costs. -

Innovation in Green Manufacturing Technologies

Dry cutting and minimum quantity lubrication (MQL) technologies reduce the use of coolants, and 100% of waste metal materials are recycled, promoting the low – carbon development of mechanical parts processing.

Inquire now and get a customized solution!

Whether it is high – precision components for aerospace, heavy – load parts for energy equipment, or core components of precision instruments, our professional team will rely on the high – precision advantages of CNC technology, combined with materials engineering and process innovation, to provide you with a full – process customization service from design, processing to inspection. Click to leave a message, and let us, with a rigorous technical system and reliable quality assurance, customize high – performance and high – stability mechanical part solutions for your project, helping you achieve technological breakthroughs and industrial upgrades in the field of industrial manufacturing!

Whether it is high – precision components for aerospace, heavy – load parts for energy equipment, or core components of precision instruments, our professional team will rely on the high – precision advantages of CNC technology, combined with materials engineering and process innovation, to provide you with a full – process customization service from design, processing to inspection. Click to leave a message, and let us, with a rigorous technical system and reliable quality assurance, customize high – performance and high – stability mechanical part solutions for your project, helping you achieve technological breakthroughs and industrial upgrades in the field of industrial manufacturing!