In the field of motorcycle manufacturing, the precision and performance of parts directly affect the vehicle’s power, handling, and safety. With the development of the motorcycle industry towards high – end and personalized directions, CNC (Computer Numerical Control) technology, with its excellent precision machining capabilities and material adaptability, has become the core technical support for customizing motorcycle parts. This article will systematically analyze the technical logic and engineering value of custom CNC motorcycle parts from dimensions such as technical advantages, materials engineering, processing techniques, quality control, and industry applications.

CNC technology provides three core technical supports for the processing of motorcycle parts through digital control and servo – drive systems:

The positioning accuracy of CNC machine tools can reach ±0.005mm, the repeat positioning accuracy is ±0.01mm, and the surface roughness Ra≤0.8μm. For example, when processing the engine crankshaft, the roundness error of the journal can be controlled within ±0.002mm, ensuring dynamic balance during high – speed rotation and reducing vibration and wear.

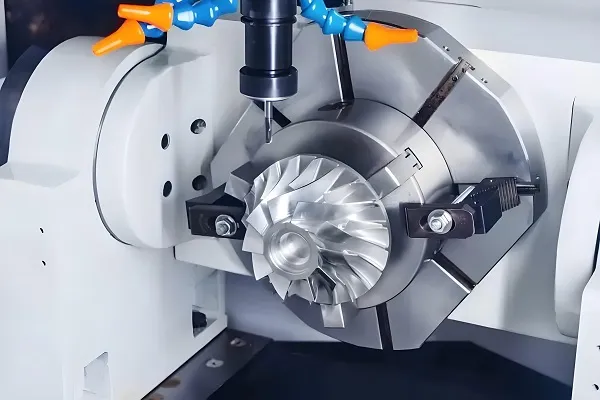

Five – axis linkage CNC equipment can achieve the processing of spatial curved surfaces, thin – wall structures (wall thickness ≤ 0.5mm), and micro – features that are difficult to complete with traditional processes. For example, the spoke surfaces of motorcycle aluminum alloy wheels can be formed in one – step through five – axis milling, reducing the weight by 30% while maintaining strength.

CNC technology is compatible with various materials such as aluminum alloys (6061, 7075), stainless steels (304, 316L), titanium alloys (TC4), and die steels (H13). According to the characteristics of different materials, cutting parameters can be optimized: when processing 7075 aluminum alloy, using high – speed cutting (HSC) technology with a rotational speed of 15000r/min and a feed rate of 2000mm/min, the efficiency can be increased by 40%; when processing titanium alloy, applying high – pressure internal – cooling tools can extend the tool life by 3 times.

Material selection is a crucial link in customizing motorcycle parts and needs to be scientifically matched according to working – condition requirements:

For frames and wheels, 6061 aluminum alloy (density 2.7g/cm³, tensile strength 290MPa) or 7075 aluminum alloy (tensile strength 572MPa) is selected. It can reduce the weight by 40% while ensuring structural strength, improving the vehicle’s acceleration and handling performance.

For suspension system components, titanium alloy (TC4, tensile strength 895MPa) is used, reducing the weight by 50% and doubling the fatigue – resistance performance, which is suitable for high – strength off – road scenarios.

For exhaust system parts, 316L stainless steel (PREN value ≥ 25) is selected, which can withstand the corrosion of high – temperature exhaust gas and has a service life of more than 10 years.

For engine transmission gears, 20CrMnTi alloy steel (with a hardness of HRC58 – 62 after carburizing) is used, increasing the wear – resistance by 5 times and ensuring long – term reliable operation.

- Economical Solutions: Q235 carbon steel after surface quenching treatment, with a hardness of HRC40 – 45, and the cost is 60% lower than that of alloy steel, is suitable for ordinary motorcycle structural parts.

- High – end Applications: Although the cost of titanium alloy parts is relatively high, in racing motorcycles, lightweight design can significantly improve performance. For example, titanium alloy bolts can reduce the weight by 60% while maintaining high strength.

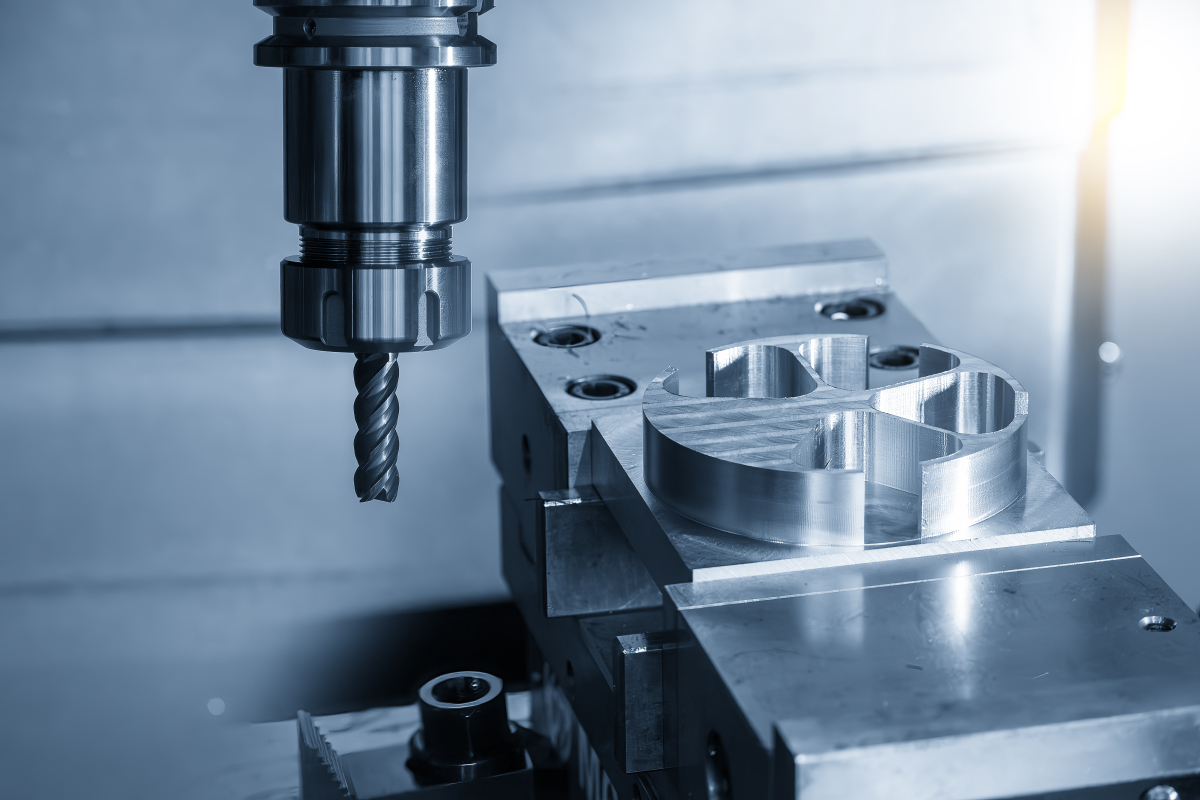

In response to the special needs of motorcycle parts, CNC processing techniques achieve a double breakthrough in efficiency and quality through the following technological innovations:

When processing aluminum alloy wheels, using solid carbide tools in combination with spiral interpolation paths can increase the material removal rate by 50% and the surface roughness Ra≤0.8μm.

When processing stainless – steel exhaust manifolds, applying TiAlN – coated tools and high – pressure internal – cooling technology can reduce the cutting temperature by 30% and extend the tool life by 2 times.

By clamping once, multi – surface processing can be completed. For example, for the special – shaped surfaces and mounting holes of motorcycle handlebars, the processing efficiency is increased by 70%, and the position accuracy reaches ±0.01mm, avoiding multiple – clamping errors.

Anodizing treatment is carried out on aluminum alloy parts. The film thickness is 10 – 20μm, which can improve corrosion resistance. It can pass a 500 – hour salt – spray test without rust, and can also be colored to meet personalized appearance requirements.

Nitriding treatment is carried out on gear components. The surface hardness is above HV900, and the fatigue life is extended by 2 times.

To ensure that products meet industry standards and riding safety requirements, custom CNC motorcycle parts need to go through a strict quality control process:

Using a coordinate measuring machine (CMM) for full – size scanning, the tolerance of key dimensions (such as the diameter of the crankshaft) is controlled within ±0.005mm.

Geometric tolerance detection: roundness error ≤ 0.003mm, coaxiality ≤ 0.01mm, ensuring the assembly accuracy of parts.

Spectral analysis is used to confirm the material composition. For example, the zinc content of 7075 aluminum alloy should be ≥ 5.1 – 6.1%.

Tensile tests, impact tests, and hardness tests are carried out to ensure that the mechanical properties meet standards such as GB/T 3190. For example, the yield strength of TC4 titanium alloy should be ≥ 825MPa.

Dynamic balance tests are carried out on wheels, and the unbalance amount should be ≤ 15g to ensure high – speed rotation stability.

Fatigue tests are carried out on suspension components. The number of cycles should reach 1 million times without cracks to ensure long – term use safety.

Custom – made 7075 aluminum alloy pistons are precisely milled by CNC. The ellipticity error of the skirt is ≤ 0.01mm, which makes the fit with the cylinder block closer and improves the engine efficiency by 5%.

20CrMnTi alloy – steel gears are processed by CNC hobbing. The tooth profile accuracy reaches ISO 6, reducing the transmission noise by 10dB and extending the service life by 3 times.

6061 aluminum alloy frames are milled by five – axis CNC, reducing the weight by 35% and increasing the torsional stiffness by 20%, improving the vehicle’s handling accuracy.

The TC4 titanium – alloy rear swingarm reduces the weight by 40% while the tensile strength is ≥ 895MPa, which is suitable for high – performance off – road motorcycles.

Custom – made stainless – steel (304) exhaust pipes are bent and polished by CNC. The inner – wall roughness Ra≤0.8μm, reducing the exhaust resistance by 15%. At the same time, the high surface gloss improves the vehicle’s texture.

Aluminum – alloy (6061) handlebar risers are engraved with personalized patterns by CNC. The surface roughness Ra≤0.4μm, which has both aesthetic and anti – slip functions.

- What is the precision of custom CNC motorcycle parts?

CNC processing can achieve a dimensional tolerance of ±0.005mm, a repeat positioning accuracy of ±0.01mm, and a surface roughness Ra≤0.8μm, meeting the requirements of high – precision components such as engines.

- How to choose the suitable materials?

It is necessary to choose according to the functions and working conditions of the parts. For example, aluminum alloy or titanium alloy is selected for lightweight, 316L stainless steel is selected for corrosion resistance, and alloy steel after heat treatment is selected for high wear – resistance.

- What is the production cycle of custom parts?

The production cycle depends on the complexity of the parts and the materials. Simple parts usually take 5 – 7 days, and complex parts may take 10 – 15 days. Urgent customization is supported to shorten the delivery time.

- Can CNC processing achieve personalized appearance design?

Yes, CNC technology can achieve personalized appearance through processes such as engraving, polishing, and surface treatment. For example, patterns can be engraved on aluminum alloy parts or colored anodizing can be carried out.

- Is the cost of custom motorcycle parts higher?

The initial cost of custom parts may be higher than that of standard parts, but CNC technology can reduce the unit cost by optimizing the process. Moreover, high precision and high performance can extend the service life of parts, making it more cost – effective in the long run.

Inquire now and get a customized solution!

Whether it is high – performance racing parts that pursue lightweight or long – distance touring equipment that emphasizes durability, our professional team will rely on the high – precision advantages of CNC technology, combined with materials engineering and process innovation, to provide you with a full – process customization service from design, processing to inspection. Click to leave a message, and let us, with a rigorous technical system and reliable quality assurance, customize high – performance and personalized CNC part solutions for your motorcycle, helping you unleash extreme performance and unique charm in the two – wheeled world!