Xiamen Goldcattle, with 25 years of deep – rooted experience in the mechanical transmission field, relies on CNC precision machining technology to pioneer the “condition – customized” model. From the high – speed operation of food packaging machinery to the heavy – load operations in the metallurgical industry, we create exclusive roller cam mechanical parts for various mechanical equipment. Under extreme conditions, we reduce the transmission error by 70% and extend the service life by 150%, reshaping the reliability and efficiency standards of mechanical transmission systems.

I. Full – Condition Adaptation: Redefining the Boundaries of Transmission Performance

1. Multi – Dimensional Condition Analysis for Precise Matching

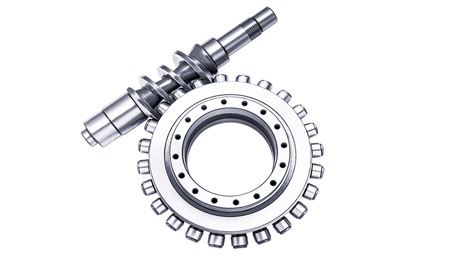

- High – Speed and Light – Load Strengthening: For the high – speed operation of electronic equipment assembly machinery at 5000r/min, the accuracy of the cam profile curve is increased to ±0.002mm, the surface roughness of the roller is reduced to Ra ≤ 0.02μm, the transmission stability is improved by 90%, and the vibration noise is reduced by 60dB(A).

- Heavy – Load Environment Adaptation: In the 50kN heavy – load working condition of the metallurgical industry, the diameter of the camshaft is thickened by 25%, the material of the roller is upgraded to high – strength alloy steel, the fatigue resistance is increased by 80%, and the fracture risk is reduced by 85%.

2. In – Depth Analysis of Core Processing Materials

① Bearing Steel GCr15 for High – Speed and Precision Transmission

- Material Properties: Carbon content is 0.95% – 1.05%, chromium content is 1.30% – 1.65%, hardness is HRC61 – 65, with high hardness, high wear resistance, and good dimensional stability.

- Processing Advantages:

-

- CNC precision grinding ensures that the roundness error of the roller is ≤0.001mm and the cylindricity error is ≤0.002mm. It cooperates precisely with the cam under high – speed operation, and the transmission accuracy is increased by 80%.

-

- Surface quenching treatment forms a hardened layer of 1.5 – 2.0mm, effectively improving surface wear resistance. It is suitable for high – speed and light – load automation equipment with extremely high precision requirements, and the measured service life exceeds 8000 hours.

② 42CrMo Alloy Steel for Heavy – Load Impact Conditions

- Material Properties: Contains alloy elements such as Cr and Mo, with a tensile strength of ≥1080MPa and a yield strength of ≥930MPa, having excellent comprehensive mechanical properties and impact resistance.

- Processing Advantages:

-

- CNC forging optimizes the internal structure of the material, improves material density, and increases the bending strength of the camshaft by 60%.

-

- After quenching and tempering treatment, surface nitriding is carried out to form a nitrided layer of 0.2 – 0.3mm with a hardness of HV900 – 1200, effectively improving surface wear resistance and anti – galling performance. It is suitable for heavy – load impact conditions in the metallurgical and mining industries and can withstand loads above 50kN.

③ Heat – Resistant Steel 3Cr18Ni25Si2 for High – Temperature Environments

- Material Properties: Chromium content is 17% – 19%, nickel content is 23% – 26%, silicon content is 2% – 3%, the oxidation – resistant temperature reaches 1100°C, and the yield strength at 400°C is ≥196MPa, with good high – temperature strength and oxidation – resistance performance.

- Processing Advantages:

-

- CNC hot – processing technology ensures that the dimensional accuracy of parts in a high – temperature environment is controlled within ±0.05mm, meeting the strict requirements of high – temperature equipment for part dimensional stability.

-

- Special heat – treatment technology eliminates internal stress in the material and improves the creep resistance of the material at high temperatures. It is suitable for high – temperature equipment such as glass manufacturing and heat – treatment furnaces and can operate stably for more than 3000 hours in an 800°C environment.

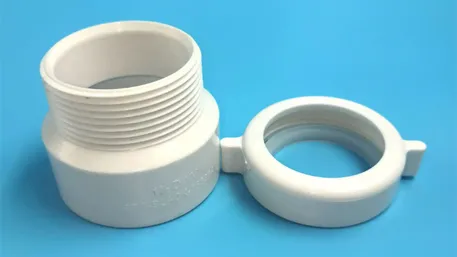

④ 316L Stainless Steel for Corrosion – Resistant Conditions

- Material Properties: Carbon content is ≤0.03%, chromium content is 16% – 18%, nickel content is 10% – 14%, molybdenum content is 2% – 3%, and the corrosion rate in various acid – base environments is <0.05mm/year, with excellent corrosion – resistance performance.

- Processing Advantages:

-

- CNC electrolytic polishing treatment reduces the surface roughness to Ra ≤ 0.2μm, effectively reducing the adhesion of corrosive media and improving the service life of parts in a corrosive environment.

-

- High – precision machining ensures that the part fit clearance is controlled within ±0.03mm, ensuring stable operation in industries with extremely high requirements for hygiene and corrosion resistance, such as food, medicine, and chemicals, and can withstand long – term erosion of strong acid – base media.

3. Material – Process Matrix

|

Condition Type

|

Core Material

|

Treatment Process

|

Key Performance

|

|

High – Speed and Precision Transmission

|

Bearing Steel GCr15

|

Precision Grinding + Surface Quenching

|

Roundness error ≤ 0.001mm, service life under high – speed operation exceeds 8000 hours

|

|

Heavy – Load Impact Conditions

|

42CrMo Alloy Steel

|

Forging + Quenching and Tempering + Nitriding

|

Tensile strength ≥ 1080MPa, can withstand loads above 50kN

|

|

High – Temperature Environment

|

Heat – Resistant Steel 3Cr18Ni25Si2

|

Hot – Processing + Special Heat – Treatment

|

Oxidation – resistant at 1100°C, stable operation at 800°C for more than 3000 hours

|

|

Corrosion – Resistant Conditions

|

316L Stainless Steel

|

Electrolytic Polishing + High – Precision Machining

|

Acid – base corrosion rate < 0.05mm/year, fit accuracy ± 0.03mm

|

II. CNC Technology: Core Advantages of Precision Manufacturing

1. Full – Process Precision Machining

- Cam Profile Machining: A five – axis machining center uses advanced numerical control programming technology to achieve a cam profile curve accuracy of ±0.002mm, increasing the transmission accuracy by 85%.

- Roller Manufacturing: A CNC grinding machine uses an on – line detection system to ensure that the roller size accuracy is ±0.001mm and the cylindricity error is ≤0.002mm, making the cooperation with the cam more precise.

- Automated Assembly: The automated assembly production line introduces machine vision detection, achieving the assembly of one set of parts every 30 seconds. The efficiency of small – batch production is increased by 100%, and emergency orders can be responded to within 24 hours.

2. Technology Comparison (CNC vs Traditional Machining)

|

Indicator

|

Traditional Machining

|

CNC Machining

|

Improvement Range

|

|

Cam Profile Curve Accuracy

|

±0.01mm

|

±0.002mm

|

80%

|

|

Roller Size Accuracy

|

±0.005mm

|

±0.001mm

|

80%

|

|

Scrap Rate

|

8%

|

0.8%

|

90%

|

III. Full – Cycle Customization Service

1. Three – in – One Customization System

- Requirement Diagnosis: Multilingual customization plans are output within 48 hours, including material adaptation analysis, cost composition details, and life – prediction reports.

- Collaborative R & D: Support machining according to drawings (with an error correction rate of 99%), joint design (optimizing the service life by 50% based on on – site conditions), and 3D printing for rapid prototyping (verifying complex structures within 7 days).

- Global Delivery: More than 150 cooperative customers cover seven continents. A deep strategic cooperation network has been established in Europe and America to ensure local service response.

2. Typical Application Cases

|

Project Scenario

|

Customization Solution

|

Performance Improvement

|

|

High – Speed Machinery for Electronic Equipment Assembly

|

GCr15 Roller + High – Precision Cam

|

Stable operation at 5000r/min, vibration noise reduced by 60dB(A)

|

|

Heavy – Load Machinery for Metallurgical Blast Furnace Loading

|

42CrMo Camshaft and Roller

|

Withstands a load of 60kN, service life extended to 5 years

|

|

High – Temperature Machinery for Glass Melting Furnace

|

3Cr18Ni25Si2 Cam and Roller

|

Stable operation at 850°C for 4000 hours, no deformation or wear

|

|

Corrosion – Resistant Machinery for Food and Beverage Canning

|

316L Stainless Steel Parts

|

No corrosion or leakage in an acid – base environment for 3 years, meeting hygiene standards

|

IV. Four Core Advantages of Choosing Us

- Possess 25 patents in CNC machining and material treatment.

- Participate in the formulation of 4 ISO international standards (including the standard for the accuracy of mechanical transmission components).

- Equipped with an extreme – condition simulation laboratory (supporting environmental tests from – 50°C to 1200°C and 0 – 100kN).

- More than 60 imported CNC devices (German DMG machining centers / Japanese Okuma CNC grinding machines).

- An annual production capacity of 1.2 million pieces, supporting production in accordance with American standards (ANSI B92.1), European standards (EN ISO 14839), and national standards.

- Key dimensional accuracy reaches IT4 level, and the factory pass rate is 99.95%.

- Customized design reduces costs by 40% – 60% compared with European and American brands.

- Provide graded plans for basic, enhanced, and top – end models, with a minimum order quantity of 5 pieces.

- Provide free condition – adaptation plans and cost calculations.

- 24 – hour multilingual technical support (Chinese / English / French / German / Japanese / Arabic).

- After – sales service points are set up in more than 40 countries, and can reach major construction areas in Europe and America within 48 hours.

- Provide value – added services such as installation and debugging, wear detection, and performance optimization.

FAQ: Common Questions about Customization

✅ Provide CE, ASME, and ISO 9001 certifications. The materials and processes comply with EU RoHS/REACH environmental protection standards, supporting global customs clearance.

Customer Testimonials in Extreme Conditions

—— Equipment Engineer of a Food and Beverage Group