As a national specialized and sophisticated enterprise with 25 years of focus on high-end precision die casting, GOLDCATTLE Die Casting always takes “micron-level precision • full-link innovation” as its core. We provide customized aluminum alloy and zinc alloy die casting services for over 30 well-known global telecommunications brands. With an annual delivery of more than 10 million telecommunications components, a yield rate of 98% for 0.5mm thin-walled parts, and an electromagnetic shielding effectiveness of ≥60dB, we define a new benchmark for precision die casting with our exclusive solutions tailored to the telecommunications industry.

- Telecommunications Product Die Castings: The Core Vessels of the 5G Era

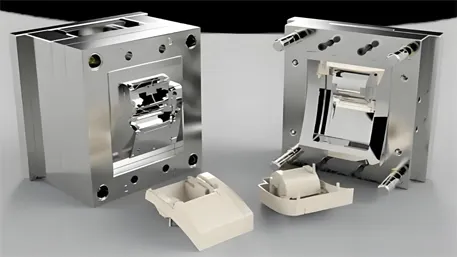

- Six-Dimensional Customization Process: Precise Mapping from ID Design to Mass Delivery

- Four Core Technologies: Solving the Three Key Pain Points of Telecommunications Components

- Full-Process Precision Control: Defining the Ceiling of Industry Precision

- Agile Service System: Matching the Rapid Iteration Needs of Telecommunications Products

- Telecommunications Die Casting FAQs: Your Dedicated Technical Advisor at Your Service

The requirements of telecommunications products for die castings, namely “precision, lightweight, and functionality,” are driving die casting technology to new heights:

- Aluminum Alloys (ADC12/A6061):

- Thermal conductivity ≥180W/(m·K), meeting the heat dissipation requirements of high-power devices in 5G base stations (e.g., the temperature of power amplifier module housings ≤65°C).

- Density of 2.7g/cm³, 50% lighter than zinc alloy, helping to reduce the weight of mobile phones (the weight of single-piece die castings ≤15g).

- Anodic oxidation film thickness of 5 – 15μm, enabling matte, high-gloss, or gradient colors (color deviation ΔE≤1.0).

- Zinc Alloys (Zamak 3):

- Electromagnetic shielding effectiveness ≥60dB (when the coating thickness is 8μm), effectively blocking signal interference (e.g., the attenuation rate of router shielding covers >99%).

- Dimensional accuracy at CT4 level (±0.03mm), suitable for precise connector pin holes (hole diameter tolerance ±0.02mm).

- Consumer Electronics: Mobile phone frames (wall thickness 0.8mm, flatness ≤0.1mm), wireless earphone charging cases (surface roughness Ra≤0.4μm).

- Network Equipment: Router heat dissipation housings (fin height tolerance ±0.05mm), 5G base station filter cavities (geometric tolerance ±0.03mm).

- Wearable Devices: Watch cases (dimensions ≤45mm×45mm, weight ≤20g), AR glasses brackets (complex curved surface fitting accuracy ±0.02mm).

- Appearance Definition:

- Accept ID drawings (STP/IGS format), lock in surface treatment processes (anodic oxidation, micro-arc oxidation, in-mold injection), and provide samples of more than 20 surface effects such as leather texture, brushing, and CD pattern (sample cycle: 3 days).

- Structural optimization: For the undercut structure of mobile phone frames, design 3 sets of slider molds (demolding draft angle 0.5° – 1°) to ensure that the assembly gap after CNC machining ≤0.05mm.

- Function Definition:

- Heat dissipation parts: Simulate the heat flow path through Flotherm, optimize the fin spacing (recommended 2 – 3mm) and thickness (1.2 – 1.5mm), and ensure that the thermal resistance ≤5°C/W.

- Shielding parts: Calculate the thickness of the electromagnetic shielding layer (recommended 8μm zinc alloy coating or 1μm aluminum alloy conductive oxidation), and simulate a shielding effectiveness pass rate ≥99%.

- Mirror-Finish Mold Technology:

- The cavity is made of imported Japanese SKD61 steel, ultra-precision polished for 12 hours (Ra≤0.1μm), and coated with PVD titanium (film thickness 3μm), achieving a “zero orange peel” surface for mobile phone frames (gloss ≥90GU).

- Precision insert design: For 0.3mm micro holes (such as earphone holes), use tungsten steel cores (hardness HRC65), with dimensional accuracy controlled at ±0.01mm.

- Enhanced Mold Flow Analysis:

- Exclusive solution for thin-walled parts (0.5mm): Increase the inner gate speed to 60m/s, injection pressure to 150MPa. Predict the position of weld lines through Moldflow and add exhaust slots (depth 0.03mm) in corresponding areas of the mold.

- Intelligent Die Casting Islands:

- Equipped with 100 – 500T cold chamber die casting machines, injection position accuracy ±0.02mm, real-time mold temperature monitoring (deviation ±2°C), ensuring that the dimensional fluctuation of 5G base station housings ≤±0.03mm/m.

- Vacuum die casting technology: Vacuum degree ≤50mbar, reducing the porosity to less than 0.5% and avoiding the attenuation of shielding effectiveness caused by internal defects of signal shielding parts.

- Precision Machining:

- Mobile phone frames are processed by five-axis CNC machines (positioning accuracy ±0.005mm), with edge R – angle error ≤±0.01mm, achieving seamless fitting of 2.5D curved surfaces with the screen.

- Connector port tapping: Use German automatic feed taps, with pitch accuracy ±0.003mm, and the pass rate of go – no – go gauge detection is 100%.

- Surface Treatment Matrix:

- Anodic oxidation line: Supports 16 – bit Pantone color customization, film thickness uniformity deviation ≤5%, passing the salt spray test for 48 hours without corrosion (meeting the requirements of outdoor telecommunications equipment).

- In – Mold Decoration (IMD): Achieves 3D curved surface printing, with adhesion ≥5N/cm (cross – hatch test), and abrasion resistance ≥100,000 times (3 times better than industry standards).

- Accuracy Inspection: Coordinate Measuring Machine (CMM) detects flatness (≤0.05mm/100mm), perpendicularity (≤0.03mm), and the diagonal dimension tolerance of mobile phone frames is ±0.02mm.

- Function Inspection:

- Electromagnetic shielding box test (frequency 1 – 10GHz), shielding effectiveness ≥60dB (10dB better than industry standards).

- Air tightness test (pressure 10kPa), leakage rate of 5G waterproof housings ≤5cc/min (meeting IP67 level).

- Rapid Prototyping: Simple molds (resin molds or aluminum molds) can deliver the first sample within 7 days, supporting rapid ID design verification (prototype pass rate 95%).

- Mass Production: The intelligent production scheduling system balances the needs of multi-variety and small-batch production (minimum batch 500 pieces), and the order change response time ≤24 hours.

- High-Speed Filling Control: Increase the injection speed to 80m/s, and with 3D printed conformal runners (reducing pressure loss by 20%), achieve 100% filling for 0.5mm wall thickness (length-width ratio >10:1) (industry average 85%).

- Cooling System Revolution: Embed micro heat pipes (diameter 1mm) in the mold, increasing local cooling efficiency by 30% and avoiding shrinkage of thin-walled parts (shrinkage rate ≤0.3%).

- Integrated Design of Datum Surfaces: Directly form assembly datum bosses (height tolerance ±0.01mm) in the die casting mold, reducing the secondary positioning error of CNC machining (traditional process error ±0.03mm).

- Automated Tool Setting System: During machining, automatically compensate for mold wear through a laser tool setting instrument (compensation accuracy ±0.002mm), ensuring dimensional stability of ≥99.5% in continuous production of 100,000 pieces.

- Optimization of Shielding Layer Thickness: Determine the optimal coating thickness (shielding effectiveness reaches 65dB when zinc alloy is nickel-plated to 8μm) through CST electromagnetic simulation, improving efficiency by 15% compared with empirical designs.

- Grounding Structure Design: Add 0.2mm high conductive bumps (spacing 5mm) at the edge of the shielding cover to ensure that the grounding resistance with the PCB board ≤50mΩ.

- Structural Topology Optimization: Use Altair Inspire for lightweight design, reducing materials by 30% while maintaining strength (e.g., reducing the weight of router housings from 28g to 19g) and increasing stiffness by 20%.

- Application of Magnesium Alloys: AZ91D magnesium alloy die castings have a density of 1.8g/cm³, 33% lighter than aluminum alloy, and have been applied to high-end AR glasses frames (single weight ≤12g).

- Aluminum Alloys: Control the Si content within 11.5% – 12.5% (deviation ±0.1%), Fe≤0.9% (spectral analysis accuracy 0.01%), ensuring no “black spot” defects after anodic oxidation.

- Zinc Alloys: Pb+Cd+Hg≤5ppm (detected by ICP-MS), avoiding “zinc pest” blistering during electroplating (the incidence rate has decreased from 1% in the industry to 0.05%).

- Collect 32 parameters per molding cycle (injection pressure, mold temperature, filling time), and real-time linkage through the PLC system and MES. When the parameter fluctuation exceeds ±2%, automatically stop for calibration.

- Mold life management: Mandatory inspection after the core has been used 10,000 times (replace when the wear amount >0.005mm), ensuring that the dimensional Cpk of continuous production ≥1.67.

- Thermal Shock: Cycle 500 times at -40°C – 85°C, with the dimensional change of mobile phone frames ≤0.02mm (industry standard 0.05mm).

- Drop Test: Drop 10 times from a height of 1.5m on six sides, with no cracks or deformation of die castings (meeting MIL-STD-810G standard).

- Early Intervention: Participate in customer ID design reviews, provide mold parting suggestions (e.g., avoiding deep cavity undercut structures, reducing mold costs by 20%).

- Joint Development: Co-build a 5G material database, recommend low-dielectric-loss alloys (dielectric constant ≤6.0) for high-frequency devices, and reduce signal attenuation.

- Emergency Response: Keep 5 sets of general mold substrates in stock, and compress the delivery cycle of complex structure molds to 4 weeks (industry average 6 – 8 weeks).

- Quality Traceability: Assign a unique QR code to each product. By scanning the code, you can check die casting parameters, inspection data, and production teams, achieving problem tracing within 10 seconds.

- On-Site Service: Provide on-site process support for strategic customers (e.g., 24-hour on-site support during new product ramp-up, increasing the yield rate to 98%).

- Continuous Optimization: Collect assembly feedback every quarter, and have helped customers optimize the structural design of telecommunications equipment 89 times in total, increasing assembly efficiency by 15%.

A: Currently, the mature process can stably produce parts with a wall thickness of 0.5mm (such as the sides of mobile phone frames). The production of 0.3mm wall thickness parts is under sample verification (yield rate 85%).

A: Yes, anodic oxidation gradient processes (such as red-blue gradients) are supported. The gradient color is achieved through two oxidation coloring processes, with the color transition area ≤1mm, and it has been applied to high-end mobile phone casings.

A: We provide shielding effectiveness inspection reports (≥60dB in the 1 – 10GHz frequency band), and third-party inspections can be carried out according to the GJB 6190-2008 standard.

A: Standard process: 3 days for requirement confirmation → 10 days for mold design → 20 days for mold machining → 5 days for trial molding → 3 days for production preparation, totaling about 41 days (15% faster than the industry average).

In the development trend of “lightweight, thin, and precise” telecommunications products, with 25 years of technical accumulation, we offer you a full-process precision solution from material selection to surface treatment. Leave a message now with your customization requirements for telecommunications products to obtain an exclusive DFM analysis report and rapid prototyping plan, and let every die casting become a quality cornerstone of the 5G era!

(Message area: Please specify the product type (mobile phone, base station, router, etc.), material requirements, and surface treatment process. We will reply within 24 hours.)