Building or modifying a vehicle often hits a roadblock when it comes to the driveshaft—off-the-shelf parts rarely fit custom setups, and mismatched components lead to vibration, premature wear, or even dangerous failures. That’s where custom driveshaft kits change the game. At Xiamen Goldcattle, we’ve spent over a decade crafting complete driveshaft solution kits that take the guesswork out of drivetrain upgrades, serving hot rod builders, off-road enthusiasts, and custom shops across the U.S. and Europe. Whether you’re swapping engines, lifting a truck, or building a one-of-a-kind vehicle, our kits come with everything needed for a seamless installation.

Why Custom Driveshaft Kits Beat Piecemeal Parts

Any experienced builder knows that assembling a driveshaft from separate components is a recipe for frustration. Custom kits solve these common headaches:

- Perfect compatibility between all components—no more mismatched yokes, flanges, or balancing issues

- Pre-engineered for your exact vehicle setup, saving hours of measurement and trial-and-error

- Balanced as a complete system, not individual parts, ensuring vibration-free operation at any speed

- Includes all necessary hardware and accessories, eliminating missing parts or incorrect fasteners

- Backed by engineering expertise that accounts for your vehicle’s power, weight, and intended use

For anyone tired of chasing down compatible parts or dealing with post-installation problems, a custom kit delivers peace of mind with every component working in harmony.

What Makes Our Custom Driveshaft Kits Unique

We design each kit around your specific vehicle and goals—no generic “universal” solutions here:

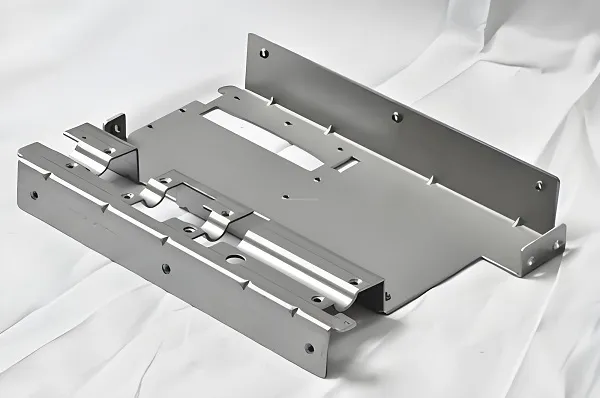

Our process starts with a detailed consultation about your build: vehicle year/make/model, engine and transmission type, lift height (for trucks/SUVs), power output, and how you’ll use the vehicle (street, off-road, racing, etc.). Using this data, our engineers design a complete system that includes:

- The perfect driveshaft (aluminum, steel, or carbon fiber, sized for your vehicle’s length and power)

- Matching end yokes or flanges that fit your transmission and differential perfectly

- High-quality U-joints rated for your torque output (greasable or sealed options)

- Balancing weights and hardware specific to your setup

- Optional extras like slip yokes, safety loops, or protective sleeves

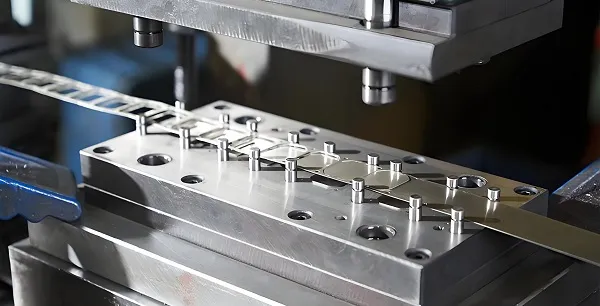

Every component is machined to precise tolerances, then assembled and balanced as a complete system before shipping. We offer kits for vehicles with single or two-piece driveshafts, and can accommodate unique setups like lifted trucks, lowered cars, or engine swaps that change drivetrain geometry.

Turnaround is surprisingly fast: most custom kits are designed and shipped within 7-10 days, with rush options available for time-sensitive builds.

Component Options for Every Application

We offer a range of materials and components to match your performance needs and budget:

-

- 6061 aluminum for the perfect balance of weight savings and strength (ideal for street performance)

-

- 4130 chromoly steel for extreme durability (great for off-road and heavy-duty applications)

-

- Carbon fiber for maximum weight reduction (perfect for racing or high-performance builds)

-

- Premium needle-bearing U-joints for smooth operation and long life

-

- High-performance U-joints rated for up to 1,500 ft-lbs of torque

-

- Sealed designs for low-maintenance off-road use or greasable options for street vehicles

-

- Billet aluminum yokes for lightweight strength

-

- Forged steel flanges for heavy-duty applications

-

- Custom adapters for non-standard transmissions or differentials

Every component meets or exceeds industry standards, with material certifications and performance ratings provided with your kit.

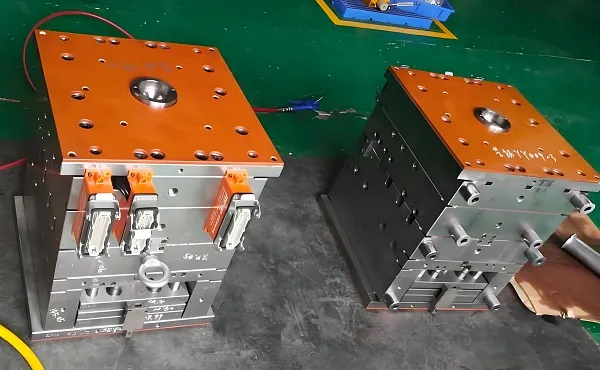

Quality Control for Complete Confidence

When your vehicle’s reliability depends on every component working together, our quality process leaves nothing to chance:

- ISO 9001:2015 certified production for consistent manufacturing standards

- Complete system balancing (up to G2.5 quality) at operating speeds up to 6,000 RPM

- Torque testing on sample assemblies to verify they handle 150% of your specified load

- Dimensional inspection of all components using CMM to ensure perfect fitment

- Final assembly check to confirm all parts work together seamlessly

Each kit comes with a detailed installation guide and a warranty covering materials and workmanship—something you won’t get from piecing together parts from different suppliers.

Builds That Benefit from Custom Driveshaft Kits

Our kits solve common challenges in these popular build scenarios:

- Engine swap projects (matching modern engines to classic drivetrains)

- Lifted or modified trucks/SUVs (correcting driveline angles after suspension changes)

- Hot rod and custom car builds (creating drivetrains from scratch)

- Off-road vehicles (beefed-up components for extreme conditions)

- Race cars (lightweight, high-strength systems optimized for performance)

- Classic car restorations (upgrading to modern components with period-correct looks)

No matter how unique your build, we’ve got the expertise to create a kit that fits perfectly.

Real-World Build Success Stories

Here’s how our custom driveshaft kits have transformed our clients’ projects:

LS Swap in a Classic Mustang

A U.S. builder was swapping a 5.3L LS engine into a 1965 Mustang, struggling to find a driveshaft that fit the modern transmission with the classic rear end. Our custom kit included a 3-inch aluminum driveshaft with a GM transmission yoke and Ford 9-inch differential flange, plus high-performance U-joints. The pre-balanced kit bolted right in, eliminating the vibration issues from their previous mismatched setup. They reported smoother acceleration and no more driveline noise at highway speeds.

Lifted Off-Road Truck

A European off-road enthusiast had lifted his Toyota Tacoma 6 inches, causing severe driveline vibration and U-joint failures. We designed a two-piece aluminum driveshaft kit with a center bearing, corrected yoke angles, and heavy-duty sealed U-joints. The kit included all mounting hardware and spacers needed for the lifted suspension. After installation, the vibration disappeared completely, and the truck completed a 1,000-mile off-road expedition without any drivetrain issues.

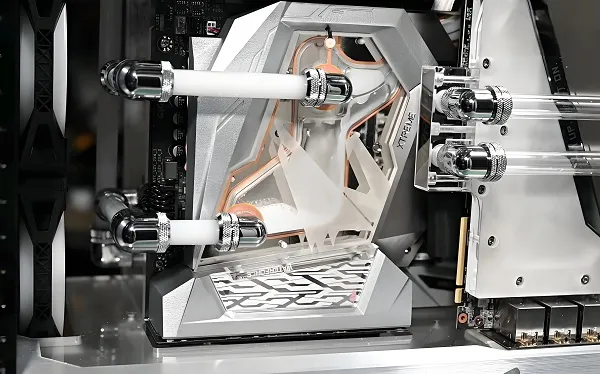

Custom Race Car Build

A racing team building a tube-frame race car needed a lightweight driveshaft system that could handle their 700hp engine. We provided a carbon fiber driveshaft kit with titanium yokes, high-speed U-joints, and a safety loop. The complete system weighed 12 pounds less than their previous steel setup and balanced perfectly at 8,000 RPM. The car set a new track record in its first race with the new drivetrain.

Why Builders Choose Our Custom Kits

After a decade of supplying driveshaft solutions, we’ve earned our reputation through:

- Engineering expertise that solves complex drivetrain challenges other suppliers avoid

- Complete systems that save hours of research, measurement, and trial-and-error

- Dedicated support for U.S. and European clients, including technical help during installation

- Flexible options for any budget or performance goal, from street builds to race cars

- Clear communication and fast turnaround that keeps projects on schedule

Ready to Simplify Your Drivetrain Build?

Need a custom driveshaft kit for your project? Send us your vehicle details, build specs, and performance goals. Our team will design a complete kit tailored to your setup and provide a detailed quote within 48 hours, including component recommendations and installation tips. Whether you’re doing an engine swap, lifting a truck, or building from scratch, we’ll provide everything needed for a perfect drivetrain solution that performs as good as it fits.