Why Every Fan Component Matters More Than You Think

The Global Market Driving Fan Component Innovation

The Science Behind Efficient Airflow: How Fan Components Work

The Basic Functions of Fan Components

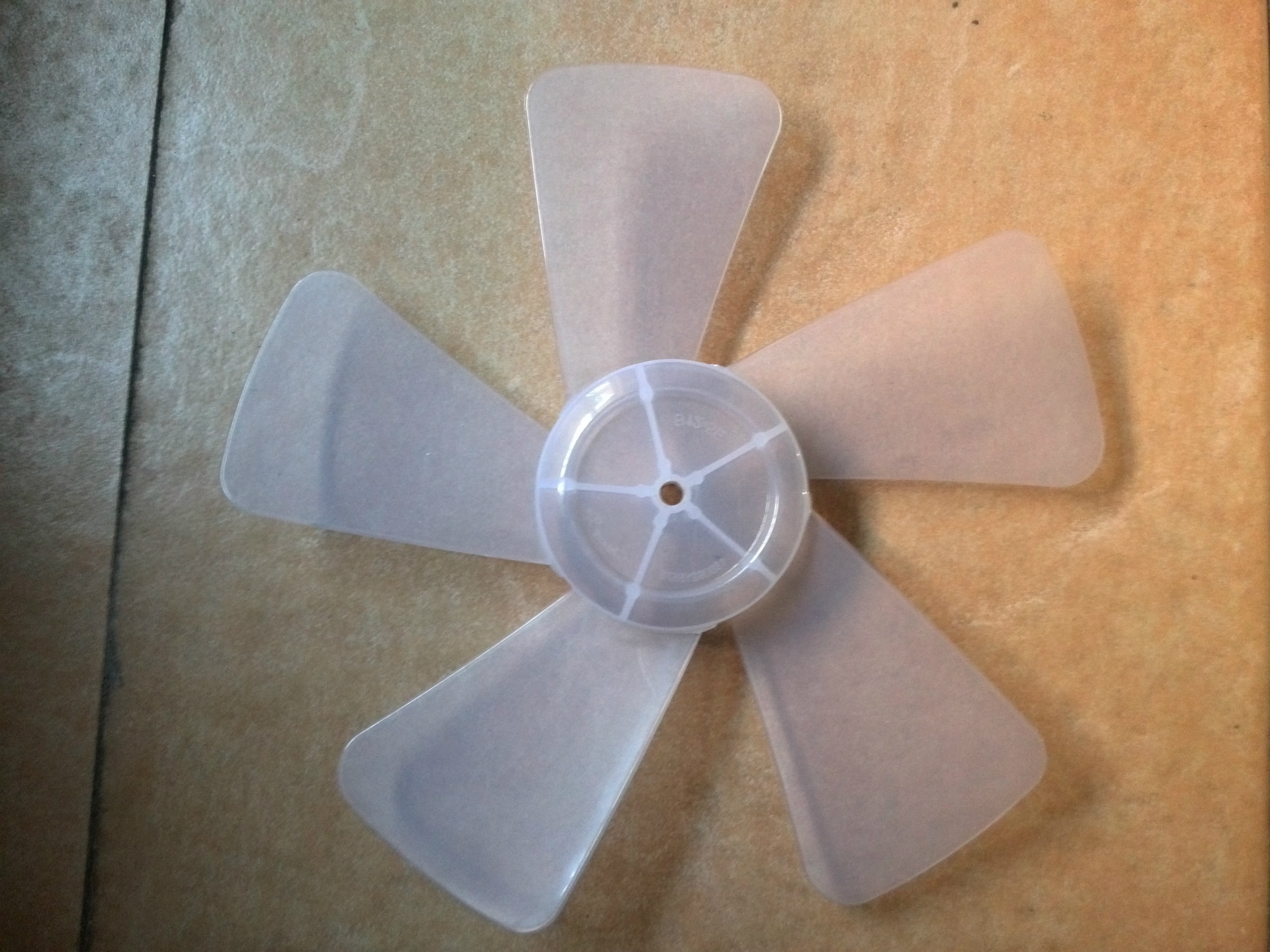

- Fan Blades: Generate airflow through aerodynamic design and precise balancing

- Motor Housings: Protect internal components while ensuring efficient heat dissipation

- Grille Assemblies: Provide safety protection while minimizing airflow resistance

- Control Knobs/Buttons: Enable user interaction with precise tactile feedback

- Mounting Structures: Ensure stability and reduce vibration transmission

Aerodynamic Principles in Fan Design

Material Science: Choosing the Right Plastic for Every Application

Material Selection Criteria

- Functional Requirements: Strength, stiffness, heat resistance, and chemical compatibility

- Processing Characteristics: Flowability, shrinkage rates, and moldability

- Environmental Factors: UV resistance, temperature stability, and humidity tolerance

- Cost Efficiency: Material cost, production yield, and lifecycle durability

Our Material Expertise

- Cost-effective solution for structural components

- Density: 0.90-0.91 g/cm³ (lightweight yet strong)

- Tensile Strength: 25-35 MPa (ISO 527, ASTM D638)

- Heat Deflection Temperature: 100-120°C

- Applications: Fan blades, housing components, control knobs

- Excellent impact resistance and rigidity

- Tensile Strength: 40-50 MPa (ISO 527, ASTM D638)

- Heat Deflection Temperature: 88-95°C

- Surface finish: High-gloss or matte options available

- Applications: Motor housings, decorative components, high-stress parts

- Superior transparency and impact strength

- Light Transmission: 88% for clear components

- Tensile Strength: 60-75 MPa (ISO 527, ASTM D638)

- Heat Deflection Temperature: 130-140°C

- Applications: Lighted components, transparent grilles, premium housings

- Excellent moldability for complex shapes

- Density: 1.04-1.06 g/cm³

- Impact Strength: 15-20 kJ/m² (ISO 179)

- Cost-effective for high-volume production

- Applications: Decorative trims, low-stress components

Advanced Material Solutions

- 30% 甘蔗 fiber reinforced PP with 42% lower carbon footprint

- Meets FDA food contact requirements

- Suitable for eco-conscious product lines

- 10-30% glass fiber reinforcement for enhanced strength

- Tensile modulus improvement: 150-250%

- Reduced warpage and improved dimensional stability

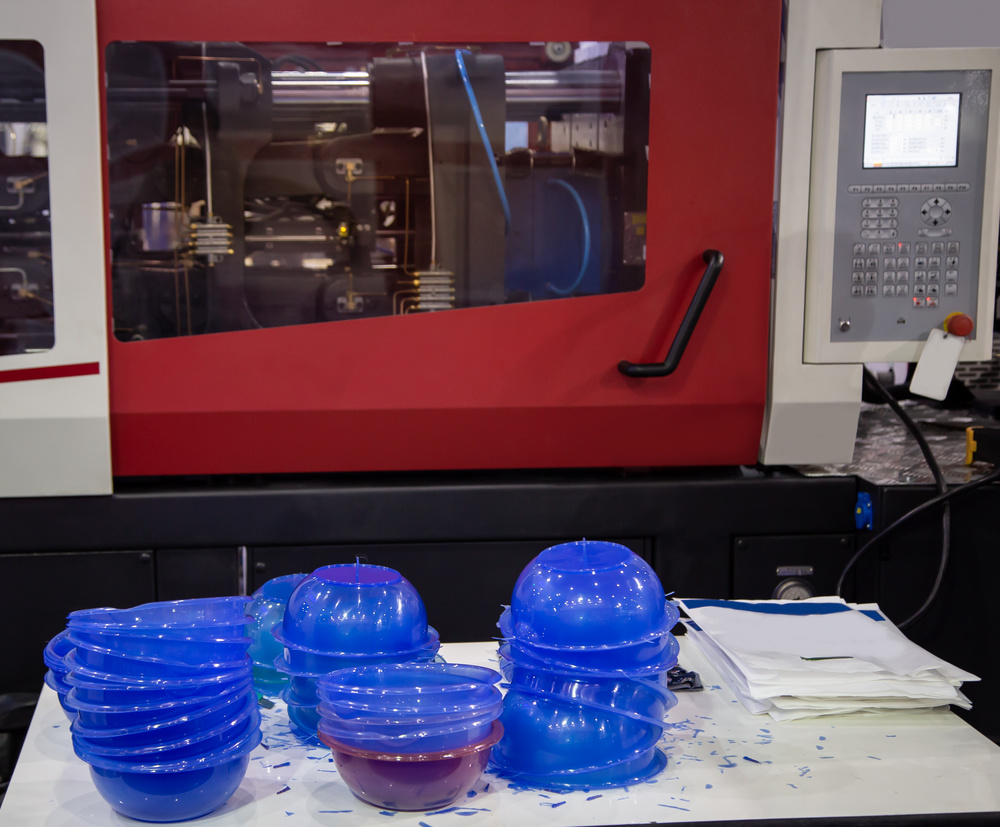

The Manufacturing Revolution: Precision Injection Molding

The Challenges of Fan Component Manufacturing

- Dimensional Accuracy: ±0.05mm tolerance for critical fit areas

- Balancing Requirements: Rotational balance within 2g·cm for vibration-free operation

- Surface Finish: Class A surfaces with no visible defects

- Temperature Resistance: Must withstand 40-85°C continuous operation

- Impact Performance: Pass 1.5m drop test requirements

Injection Molding: The Foundation of Precision

- Computer-controlled injection processes with closed-loop feedback

- Repeatability within ±0.02mm for critical dimensions

- Consistent part quality across millions of production cycles

- Ability to produce complex geometries with thin walls (0.8-1.5mm)

- Precision temperature control (±1°C) for optimal material flow

- Variable injection speed profiles for complex geometries

- Pressure holding optimization to eliminate sink marks and voids

- In-mold monitoring systems for real-time quality assurance

- Ultrasonic welding for strong, clean assembly joints

- Vibration welding for large surface area bonding

- Hot stamping for decorative logos and markings

- Pad printing for multi-color decorative elements

Mold Design Excellence: The Key to Quality

Precision Mold Engineering

- Computer simulation of filling patterns to optimize gate locations

- Prediction of weld lines, air traps, and potential defects

- Optimization of cooling channel layout for uniform solidification

- Warpage prediction and compensation

- Conformal cooling channels for uniform heat distribution

- Temperature control within ±2°C across all cavity surfaces

- Optimized cycle times through efficient heat removal

- Preventive maintenance scheduling based on thermal profiling

- Sequential ejection for complex geometries

- Precision ejector pin placement to prevent cosmetic defects

- Cushioned ejection to minimize component stress

- Self-cleaning mechanisms to prevent contamination

Our Customization Process: From Concept to Reality

Step 1: Requirements Analysis

- Functional Requirements: Airflow performance, noise targets, safety standards

- Aesthetic Goals: Surface finish, color matching, design language integration

- Performance Targets: Durability expectations, temperature range, humidity resistance

- Regulatory Compliance: UL, CE, RoHS, and regional safety standards

Step 2: Engineering Design

- 3D CAD Modeling: Parametric design with full associativity

- Finite Element Analysis: Structural integrity verification under operating conditions

- Computational Fluid Dynamics: Airflow simulation for blade optimization

- Design for Manufacturing: Production optimization from initial concept

Step 3: Prototyping and Testing

- Rapid Prototyping: SLA, SLS, or CNC machined prototypes for form and fit testing

- Functional Testing: Airflow measurement, noise testing, vibration analysis

- Environmental Testing: Temperature cycling, humidity exposure, UV resistance

- Durability Testing: Lifecycle simulation, impact testing, wear resistance

Step 4: Production and Quality Control

- Precision Molding: State-of-the-art injection molding machines with 5-axis control

- In-Process Inspection: Automated dimensional verification during production

- Statistical Process Control: Real-time monitoring of critical parameters

- Traceability: Complete production documentation and batch tracking

Quality Standards: Certifications You Can Trust

International Quality Certifications

- Quality management system certification

- Process approach with risk-based thinking

- Continuous improvement methodology

- Customer satisfaction monitoring

- Environmental management system

- Sustainable manufacturing practices

- Waste reduction and energy efficiency

- Environmental performance monitoring

- Automotive quality management system

- Applicable to fan components for automotive applications

- Advanced product quality planning (APQP)

- Failure mode and effects analysis (FMEA)

Material and Performance Standards

- RoHS Compliance: Restriction of hazardous substances

- REACH Compliance: Chemical safety standards

- FDA Compliance: Food contact safety for applicable components

- UL 94: Flammability rating (V-0 for critical components)

- IEC 60335: Household and similar electrical appliances

- UL 507: Fans and blowers safety standard

- GB 4706.27: Chinese national standard for fans

- EN 60335: European standard for electrical appliances

- ISO 286: Geometric product specifications

- ISO 527: Tensile testing of plastics

- ISO 179: Charpy impact testing

- ISO 178: Flexural properties of plastics

Technical Advantages: Why Choose Xiamen GoldCattle

Performance Comparison

|

Performance Metric

|

Industry Standard

|

Our Capability

|

Improvement

|

|

Dimensional Accuracy

|

±0.1mm

|

±0.03mm

|

70% better

|

|

Weight Consistency

|

±3%

|

±0.5%

|

83% improvement

|

|

Production Yield

|

95%

|

99.5%

|

90% reduction in defects

|

|

Cycle Time

|

45-60 sec

|

25-35 sec

|

40% faster

|

|

Tool Life

|

500,000 shots

|

1,500,000 shots

|

200% longer

|

Design and Engineering Expertise

- Aerodynamic Design: CFD-optimized blade profiles for maximum efficiency

- Noise Reduction: Acoustic engineering for quiet operation

- Material Science: Custom formulations for specific performance requirements

- Manufacturing Optimization: Process engineering for cost-effective production

Custom Solutions for Every Need

- Household Fans: Table fans, stand fans, ceiling fans, tower fans

- Industrial Fans: Ventilation systems, exhaust fans, cooling fans

- Automotive Fans: Radiator fans, HVAC systems, seat ventilation

- Electronics Cooling: CPU fans, server cooling, LED heat management

Case Study: Energy-Efficient Smart Fan Transformation

Client Challenge

- Reduce energy consumption by 25% compared to current designs

- Lower operational noise by 3dB while maintaining airflow performance

- Meet strict environmental standards for recycled material content

- Ensure consistent quality across high-volume production

Our Solution

Results

Future Trends: The Next Generation of Fan Components

Smart Technology Integration

- Sensor Integration: Built-in temperature and humidity sensors

- Variable Geometry: Adjustable blade angles for optimal performance

- Wireless Connectivity: IoT-enabled components for smart home integration

- Self-Diagnosis: Condition monitoring for predictive maintenance

Sustainable Materials and Practices

- Bio-Based Polymers: Plant-derived materials with reduced environmental impact

- Recycled Content: Increased use of post-consumer recycled plastics

- Lightweight Design: Reduced material usage through advanced engineering

- Circular Economy: Design for disassembly and recycling

Advanced Manufacturing Technologies

- 3D Printing: Rapid prototyping and small-batch production

- In-Mold Labeling: Decorative elements integrated during molding

- Microcellular Foaming: Weight reduction with maintained strength

- Artificial Intelligence: AI-optimized process parameters and quality control