I. Product Requirements Analysis

1.1 Basic Parameters of Plastic Parts

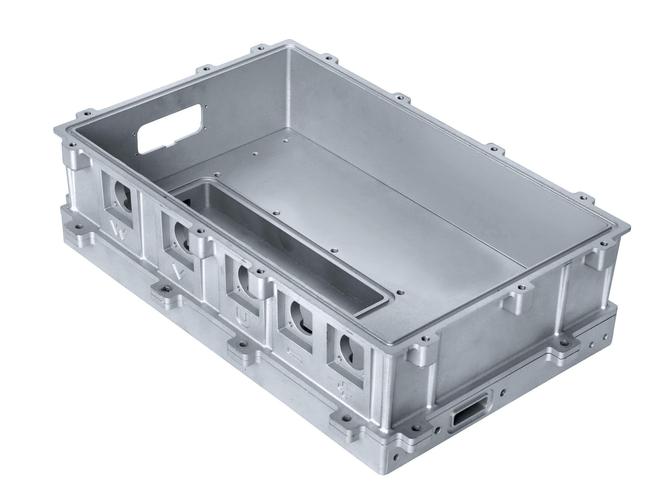

Dimensional Specifications

Standard automotive headlight plastic housing dimensions are 475.3×355.6×291.4mm, classified as large injection molded parts. Mold design must fully consider the molding characteristics of large plastic components.

Material Selection

- PP+TD2: Polypropylene base with 2% talc powder reinforcement for rigidity

- PC (Polycarbonate): Excellent impact resistance and transparency

- ABS (Acrylonitrile Butadiene Styrene): High surface hardness and dimensional stability

1.2 Technical Requirements

Appearance Quality

- No spots, shrinkage depressions, weld lines, or flash defects allowed

- Surface roughness Ra value must be controlled within 0.8μm

- Critical appearance surfaces require mirror or high-gloss finish

Assembly Precision

- Critical dimension tolerances controlled within ±0.02mm range

- Strict precision requirements for lamp holder holes, rear cover holes and other assembly positions

- Fitting clearances must meet automotive industry standards

Production Requirements

- Annual output must reach over 100,000 pieces

- Mold lifespan not less than 1,000,000 cycles

- Cycle time controlled within 40 seconds

II. Mold Design Key Points

2.1 Overall Structure Design

Parting Surface Design

- Adopt smooth, sharp corner – free surface sealing structure

- Avoid CNC machining tool chatter to ensure machining accuracy

- Parting surface width is 4mm, with 1mm clearance in other areas

Hot Runner System

- Adopt 2-point open hot runner direct gating

- Design cooling water in hot nozzle area to enhance cooling

- Main nozzle must be at least 2mm below the panel

2.2 Side Core-Pulling Mechanism

Structural Configuration

- Equipped with 6 sets of independent side core-pulling mechanisms

- Adopt “moving mold slide + angle pin” mechanical drive structure

- Slide fitting clearance controlled at 0.02-0.03mm

Design Requirements

- Core-pulling distance must meet plastic part undercut depth requirements

- Slide movement must be smooth without jamming

- Limiting mechanism must be reliable to prevent slide over-positioning

2.3 Cooling System Design

Water Channel Layout

- Adopt conformal cooling water channel design

- Water channel diameter 8-12mm, spacing 20-30mm

- Ensure temperature difference ≤5℃ in each cavity area

Special Requirements

- Dense water channels or special-shaped water channels required in thick-walled areas

- Enhanced cooling required on surfaces directly opposite hot nozzles

- Avoid shrinkage defects caused by uneven cooling

2.4 Ejection Mechanism Design

Structural Form

- Adopt multiple sets of small-diameter ejector pins for ejection

- Cooperate with sleeve ejection for slender cores

- Set up ejector plates or angle lifters when necessary

Design Principles

- Avoid applying ejection force on thin surfaces

- Prevent plastic part deformation during ejection

- Ensure smooth demolding of plastic parts

III. Material and Process Requirements

3.1 Mold Material Selection

Mold Steel Selection

S136 Stainless Steel Mold Steel

- Composition: 4Cr13Mo2Ni3 (Chinese standard), 13.6% chromium content

- Hardness: 48-52 HRC after heat treatment

- Corrosion Resistance: Excellent corrosion resistance, suitable for PVC and flame retardant plastics

- Polishing Performance: Can achieve 8000-12000 grit finish, surface roughness 0.015μm

- Applications: Transparent plastics (PC, PMMA), medical products, high cleanliness requirements

718H Pre-hardened Plastic Mold Steel

- Composition: 3Cr2NiMo (Chinese standard), 0.35-0.42% carbon, 0.8-1.2% nickel

- Hardness: HRC30-38 (HB290-340) in delivery state

- Mechanical Properties: Tensile strength 1000-1200MPa, impact toughness ≥20J/cm²

- Processing Advantages: Excellent polishing performance, good machinability

- Applications: Medium and large precision plastic molds, general plastic products

H13 Hot Work Tool Steel

- Composition: 4Cr5MoSiV1 (Chinese standard)

- Hardness: HRC45-50 after heat treatment

- Characteristics: High hardness, high wear resistance, high temperature resistance

- Applications: Glass fiber/mineral filled plastics (PA66+glass fiber, PBT+glass fiber)

- Advantages: Suitable for high-volume production, long mold life

NAK80 Precision Mirror Steel

- Polishing Performance: Excellent mirror polishing effect

- Corrosion Resistance: Good corrosion resistance

- Applications: High surface quality requirements, transparent products

Surface Treatment

- Hard chrome plating, thickness 5-10μm

- Super-finishing polishing, surface roughness Ra0.02-0.04μm

- Nitriding treatment when necessary to improve surface hardness

3.2 Injection Molding Process Parameters

Temperature Control

- Barrel temperature: 280-300℃ (for PC material)

- Mold temperature: 80-120℃

- Nozzle temperature: Slightly higher than barrel temperature

Pressure Control

- Injection pressure: 80-120MPa

- Holding pressure: 60-80% of injection pressure

- Clamping force: 20% higher than theoretical value

Time Control

- Injection time: Adjust according to plastic part size

- Holding time: 10-30 seconds

- Cooling time: Controlled within 50% of cycle time

IV. Quality Control Standards

4.1 Mold Quality Standards

Dimensional Accuracy

- Cavity dimension tolerance: IT7-IT9 grade

- Template parallelism: ≤0.02mm

- Guide pillar and bushing fitting clearance: 0.02-0.03mm

Surface Quality

- Molding surface roughness: Ra≤0.8μm

- Non-molding surfaces: Deburring and chamfering required

- Mold appearance: No obvious scratches or bumps

4.2 Plastic Part Quality Standards

Dimensional Accuracy

- Critical dimension tolerance: ±0.02mm

- General dimension tolerance: ±0.1mm

- Geometric tolerance: Meet assembly requirements

Appearance Quality

- No shrinkage marks, bubbles, flash or other defects

- Uniform and consistent surface gloss

- Color meets design requirements

Performance Requirements

- Weather resistance: Meet IP67 protection rating

- Optical performance: Light transmittance ≥92%

- Mechanical properties: Meet relevant standards

V. Supplier Selection Requirements

5.1 Technical Capability Requirements

Design Capability

- Professional designers with over 5 years of experience

- Proficiency in CAD/CAE/CAM integrated design

- Ability to perform mold flow analysis and DFM analysis

Processing Capability

- Equipped with high-speed machining centers, accuracy ±0.001mm

- Possess EDM, wire cutting and other precision processing equipment

- Have coordinate measuring machines and other testing equipment

5.2 Qualification Certification Requirements

Enterprise Qualifications

- ISO9001 quality management system certification

- ISO14001 environmental management system certification

- IATF16949 automotive industry certification when necessary

Product Certification

- Molds must meet relevant industry standards

- Materials must provide material certificates

- Heat treatment must provide test reports

5.3 Service Guarantee Requirements

Pre-sales Service

- Provide detailed technical solutions

- Conduct sufficient technical communication

- Provide reasonable quotations and delivery times

After-sales Service

- Provide 1 year or 50,000 cycle warranty

- 24-hour maintenance response mechanism

- Regular return visits and technical support

VI. Cost and Delivery Management

6.1 Cost Composition Analysis

Mold Cost

- Design cost: 10-15% of total cost

- Material cost: 30-40% of total cost

- Processing cost: 40-50% of total cost

- Trial cost: 5-10% of total cost

Price Range

- Single cavity mold: 50,000-150,000 RMB/set

- Multi-cavity mold: 150,000-300,000 RMB/set

- Specific price adjusted according to mold complexity

6.2 Delivery Cycle Management

Design Cycle

- Preliminary design: 5-7 working days

- Detailed design: 10-15 working days

- Design review: 3-5 working days

Processing Cycle

- Material preparation: 3-5 working days

- Rough machining: 10-15 working days

- Finish machining: 15-20 working days

- Assembly and debugging: 5-7 working days

Trial Cycle

- First trial: 3-5 working days

- Problem rectification: 5-10 working days

- Second trial: 3-5 working days

6.3 Acceptance Standards

Mold Acceptance

- Dimensional accuracy testing

- Appearance quality inspection

- Movement flexibility testing

- Safety performance inspection

Plastic Part Acceptance

- Dimensional accuracy testing

- Appearance quality inspection

- Mass production verification

VII. About Xiamen Golden Bull Injection Mold Customization Service

Xiamen Golden Bull is a professional manufacturer specializing in custom injection mold design and manufacturing. With years of experience in the automotive industry, we provide comprehensive mold customization solutions for headlight plastic housing and other automotive components.

Our Service Scope

Mold Design and Manufacturing

- Professional CAD/CAE/CAM design team

- Precision machining equipment and testing instruments

- Strict quality control system

Material Selection Consultation

- Professional advice on mold steel selection

- Material performance analysis and recommendation

- Cost-effective material solutions

Process Optimization

- Mold flow analysis and simulation

- Process parameter optimization

Customization Process

1. Requirements Communication

- Detailed understanding of product specifications

- Technical requirement confirmation

- Quotation and delivery time negotiation

2. Design and Engineering

- DFM analysis and feasibility study

- 3D mold design and simulation

- Design review and approval

3. Manufacturing and Processing

- Material procurement and preparation

- Precision machining and heat treatment

4. Trial and Optimization

- Mold trial and sample production

- Problem analysis and rectification

- Mass production verification

5. Delivery and Service

- Mold delivery and installation guidance

- Production process support

- After-sales service and maintenance

Quality Assurance

- ISO9001 quality management system certification

- Strict incoming material inspection

- Complete process quality control

- Comprehensive final inspection and testing

Xiamen Golden Bull is committed to providing high-quality, cost-effective injection mold solutions for customers in the automotive industry. With our professional technical team and advanced manufacturing equipment, we ensure that each mold meets the highest standards of quality and performance.

For more information about our injection mold customization services, please visit our website at https://www.xmgoldcattle.com/ or contact our sales team directly. We look forward to cooperating with you and providing you with the best mold solutions.