In the process of modern industry’s development towards high-end and precision, custom high-pressure aluminum castings, with their excellent mechanical properties, superior molding accuracy, and good lightweight characteristics, have become indispensable key components in fields such as aerospace, automotive manufacturing, and energy equipment. This article will provide an in-depth analysis of professional solutions for custom high-pressure aluminum castings, covering technical processes, material systems, quality control, and application scenarios.

- Precise Regulation of Pressure and Speed: Using large-scale 2,000 – 6,000-ton servo die casting equipment, the injection pressure can reach up to 180 MPa, ensuring that the molten aluminum alloy fills the mold cavity accurately at high speeds ranging from 8 – 50 m/s. For high-pressure aluminum castings with complex structures, thin-walled molding with a minimum wall thickness of 1.0 mm can be achieved, meeting the lightweight design requirements while guaranteeing structural strength.

- Coordinated Temperature Management: The mold temperature control system achieves an accuracy of ±2°C, and the fluctuation of the aluminum alloy melting temperature is strictly controlled within ±4°C. Through real-time monitoring by multi-zone thermocouples and intelligent adjustment, defects such as cold shuts and shrinkage porosity are effectively avoided, and the qualified rate of finished products remains stable at over 98.5%.

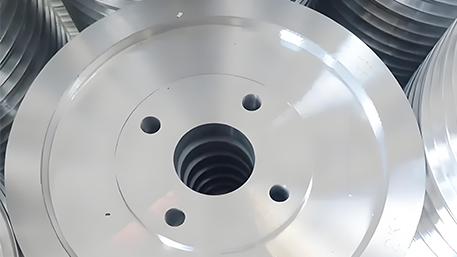

- Guaranteed Dimensional Accuracy: Strictly following the GB/T 6414 – 1999 standard, general dimensional tolerances are controlled at CT4 – CT6 levels (e.g., ±0.5 mm for a 200-mm dimension). With the help of high-precision molds and advanced processing techniques, the dimensional accuracy of key parts can reach the CT3 level (±0.25 mm), meeting the stringent assembly requirements of high-end equipment for components.

- Material and Structural Upgrades: Imported high-quality modified H13 hot work die steel (hardness 50 – 54 HRC) is selected and combined with advanced TD surface treatment technology. This increases the mold’s thermal fatigue resistance by 70% and extends its service life to over 1 million cycles. Meanwhile, the adoption of conformal cooling channel design improves the cooling efficiency by 40%, effectively shortening the production cycle.

- Digital Design and Manufacturing: Professional software such as UG and Moldflow are used for mold flow analysis and design optimization. For the complex internal structures of high-pressure aluminum castings, gate positions are precisely optimized (error controlled within ≤0.2 mm), reducing the pressure loss in the runner system to 10%. This minimizes the waste of aluminum alloy materials and enhances the molding quality and production efficiency of castings.

- High-Strength Aluminum Alloy: Through special modification treatment and heat treatment processes, the A356 aluminum alloy is strengthened, increasing its tensile strength to 430 MPa and yield strength to 380 MPa. It is suitable for critical aerospace structural components that bear high loads, such as wing beams and fuselage frames.

- High-Thermal-Conductivity Aluminum Alloy: By adding trace rare earth elements to the ADC12 aluminum alloy, the thermal conductivity is increased to 220 W/(m·K), which can effectively improve the heat dissipation efficiency of automotive engines, reduce operating temperatures, and enhance engine performance and reliability.

- Material Testing: Direct-reading spectrometers (accuracy 0.01%) are used for precise analysis of the aluminum alloy composition, strictly controlling the content of alloy elements and the proportion of impurities. Hydrogen-oxygen analyzers ensure that the hydrogen content in molten aluminum is ≤ 0.12 ml/100 g, eliminating defects such as porosity and looseness from the source.

- Dimensional and Geometric Tolerance Inspection: Coordinate Measuring Machines (accuracy ±0.005 mm) are used to conduct full-size scanning inspections of high-pressure aluminum castings. Critical dimensions are 100% inspected, while non-critical dimensions follow the AQL = 0.65 sampling standard in GB/T 2828.1, ensuring the dimensional accuracy and assembly accuracy of castings.

- Internal Defect and Performance Testing: Equipped with high-resolution X-ray flaw detectors (resolution ≤0.15 mm) and industrial CT inspection equipment, comprehensive inspections are carried out on the interior of castings to ensure there are no defects such as shrinkage cavities and inclusions. Tensile, impact, fatigue, and other mechanical property tests, as well as metallographic structure analysis, are performed on castings to ensure that product performance meets design requirements.

- Case Study: A custom high-pressure aluminum casting battery tray for a new energy vehicle brand, die cast from A356-T6 aluminum alloy. The weight of a single piece is reduced by 45% compared to traditional steel materials, weighing only 12 kg. The dimensional accuracy reaches ±0.3 mm, and the internal stiffener structure is reasonably designed, effectively enhancing the strength and rigidity of the tray.

- Technical Highlights: Vacuum die casting technology is used to control the internal porosity of the casting below 0.15%. Combined with the T6 heat treatment process, the tensile strength of the tray reaches 380 MPa, and the yield strength is 330 MPa. The heat dissipation structure is optimized through simulation to ensure the temperature uniformity of the battery under different working conditions, meeting the IP68 waterproof and dustproof rating requirements of the battery pack.

- Requirement: Develop a compressor casing for a certain type of aero-engine, which requires high strength, high-temperature resistance, and low weight.

- Solution: High-performance aluminum alloy materials are selected, and the casing is manufactured using a combination of high-pressure die casting and precision machining processes. Through optimizing mold design and die casting process parameters, precise molding of complex curved surfaces and internal flow channels is achieved. Special anodizing treatment (coating thickness 25 μm) is carried out on the surface to improve corrosion resistance and wear resistance, and shot peening treatment is performed inside to enhance fatigue life. The final product weight is reduced by 30% compared to traditional forging processes and can still maintain good mechanical properties at 600°C, meeting the stringent usage requirements of aero-engines.

- Requirement Docking: Respond to customer needs within 12 hours, deeply understand the usage scenarios, performance indicators, appearance requirements, etc., of high-pressure aluminum castings, and provide a professional DFM (Design for Manufacturability) report to clarify mold costs and production cycles.

- Mold Development: The standard mold development cycle is 5 – 8 weeks. CAD/CAE collaborative design is adopted, and mold prototypes are quickly produced using 3D printing for verification. The first-piece confirmation time is ≤48 hours.

- Production and Manufacturing: Support small-batch trial production (minimum order quantity 200 pieces). The mass production capacity can reach 200 – 500 pieces per day (depending on product size), equipped with automated production lines and online detection equipment to monitor the production process in real-time and ensure stable product quality.