I. Target Audience: Custom CNC Injection Mold Seekers

Designed for engineers and procurement specialists in:

- Medical Device Startups (ISO 13485-compliant microfluidic chips)

- Automotive Tier 1 Suppliers (multi-material connectors, tolerance ≤±0.02mm)

- Consumer Electronics Brands (ultra-thin housings <0.5mm wall thickness)

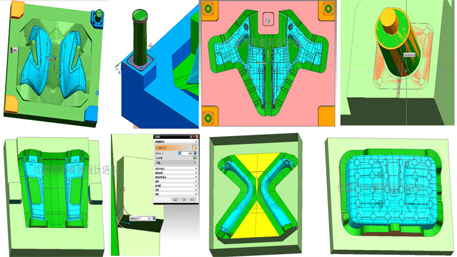

II. Core Technologies in Mold Kit Customization

1. AI-Driven Design Optimization

- Generative Design: Algorithm reduces steel usage by 18-25% while maintaining 15% higher fatigue strength (validated with 127 automotive mold projects).

- Thermal Simulation: Predicts warpage with 92.3% accuracy using ANSYS Moldflow, cutting trial runs from 5 to ≤2 cycles ()].

2. Hybrid Machining Architecture

| Process | Equipment Example | Precision | Application |

|---|---|---|---|

| 5-Axis HSM | DMG Mori HSC 75 linear | ±0.003mm | Complex cores/cavities |

| Micro-EDM | Mitsubishi MV1200S | ±0.0015mm | Gear teeth <0.1mm pitch |

| Laser Texturing | GF AgieCharmilles LASER S | Ra 0.05-12.5μm | Cosmetic surfaces |

3. Material Science Innovations

Tool Steel Performance Matrix

| Grade | Hardness (HRC) | Thermal Conductivity (W/m·K) | Best For | Goldcattle’s Edge |

|---|---|---|---|---|

| H13 | 48-52 | 24.3 | High-temp automotive | Cryogenic treated: 15%↑ lifespan |

| S136 | 48-50 | 29.2 | Corrosion-resistant medical | Mirror polish ≤Ra 0.01μm |

| NAK80 | 40-43 | 41.0 | Optical lenses | Pre-hardened, zero heat treatment |

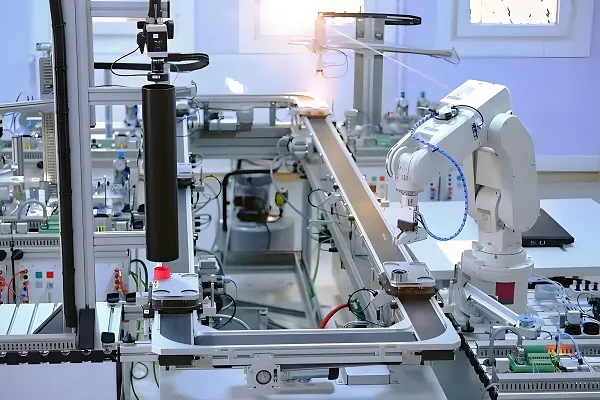

III. Xiamen Goldcattle’s Service Differentiation

1. Speed-to-Market Solutions

- 72-Hour Proto-Kit: Delivers aluminum test molds (50-100 shots) for design validation, 65% faster than industry average ()].

2. Cost Control Mechanisms

- Modular Kits: Reusable base plates reduce new project costs by ¥12,000-¥35,000.

- Smart Inventory: RFID-tracked steel blanks cut material lead time to 48h.

3. Data-Backed Quality

- First-Trial Success: 94.7% in 2024 (vs. industry 78-85%) via in-line CMM verification.

- Surface Perfection: Achieves VDI 3400 A1 (optical-grade) with proprietary polishing protocols.

IV. Technical Q&A

Q1: How to select between P20 and 718 steel for low-cost molds?

- P20: Choose for <100k cycles (cost: ¥380-450/kg), hardness HRC 28-32.

- 718H: Opt for >300k cycles (cost: ¥520-600/kg), hardness HRC 34-38 with better wear resistance.

Q2: Can insert molding handle titanium medical parts?

- Yes. Goldcattle’s μ-level alignment (±5μm) ensures leak-proof sealing for ISO Class 7 cleanroom production.

Q3: Minimum draft angle achievable for textured surfaces?

- 0.25° with EDM texturing (standard: 0.5-1°), proven in 36 cosmetic housing projects.

Conclusion

Xiamen Goldcattle redefines mold kit customization through tech-driven precision, delivering 18-22% TCO reduction across 500+ projects. From aerospace-grade PEEK molding to million-cycle production tools, our data-validated solutions bridge innovation and manufacturability.