What B2B Buyers Need to Know in 2025–2026

Discover the latest trends in custom injection mold manufacturing, including tooling automation, digital sourcing platforms, and global supply chain shifts. A practical guide for B2B buyers and procurement teams selecting reliable mold partners.

Introduction

For product engineers and procurement managers, the injection mold is no longer just a tool—it’s the foundation that determines final part cost, quality consistency, and time-to-market. In today’s competitive manufacturing landscape, where product lifecycles are shrinking and customer expectations are rising, choosing the right custom injection mold manufacturer has become more critical than ever.

According to the latest industry report by Grand View Research, the global plastic injection mold market is projected to grow at a 6.2% CAGR through 2030, reaching $45.2 billion by the end of the forecast period. This growth is driven by increasing demand for complex plastic components across automotive, medical, consumer electronics, and packaging industries.

This guide will explore the key trends shaping custom injection mold manufacturing in 2025–2026, and provide practical insights to help you make more informed decisions when selecting an injection mold tooling partner. We’ll cover everything from the evolution of mold making capabilities to digital sourcing platforms and global supply chain shifts.

Why Custom Injection Mold Tooling Is Now a Strategic Make-or-Break Decision

The injection mold is often called the “mother of all products” in plastic manufacturing, and for good reason. 70-80% of the final part cost is determined by the mold design and quality, not the production process itself. This means that the decision to invest in high-quality custom injection mold tooling can have a profound impact on the entire product lifecycle.

Custom vs. Standard Injection Molds

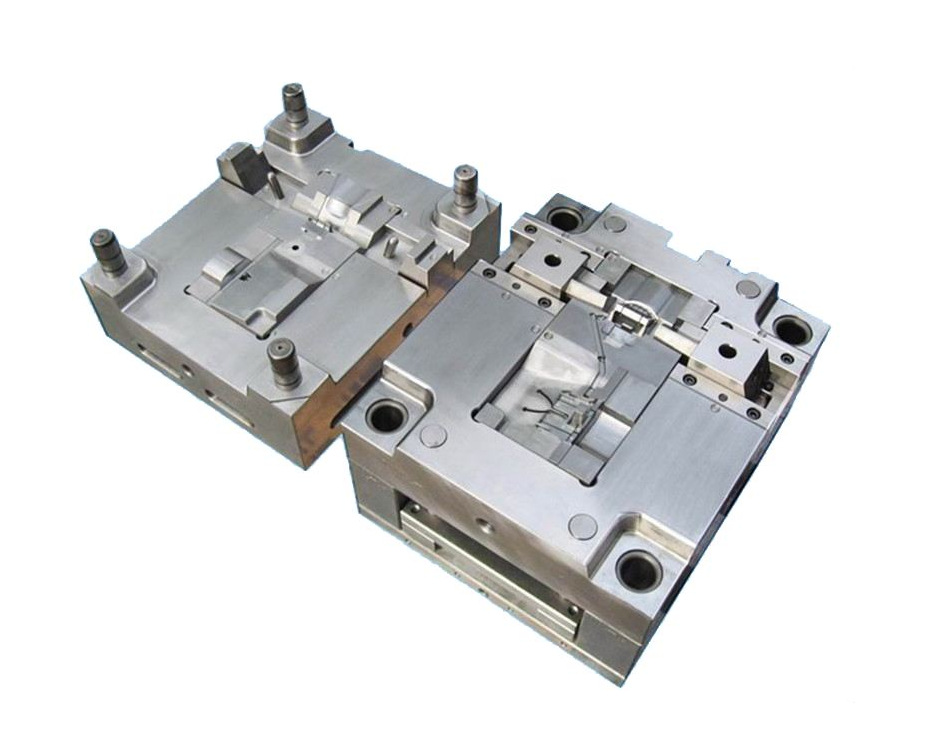

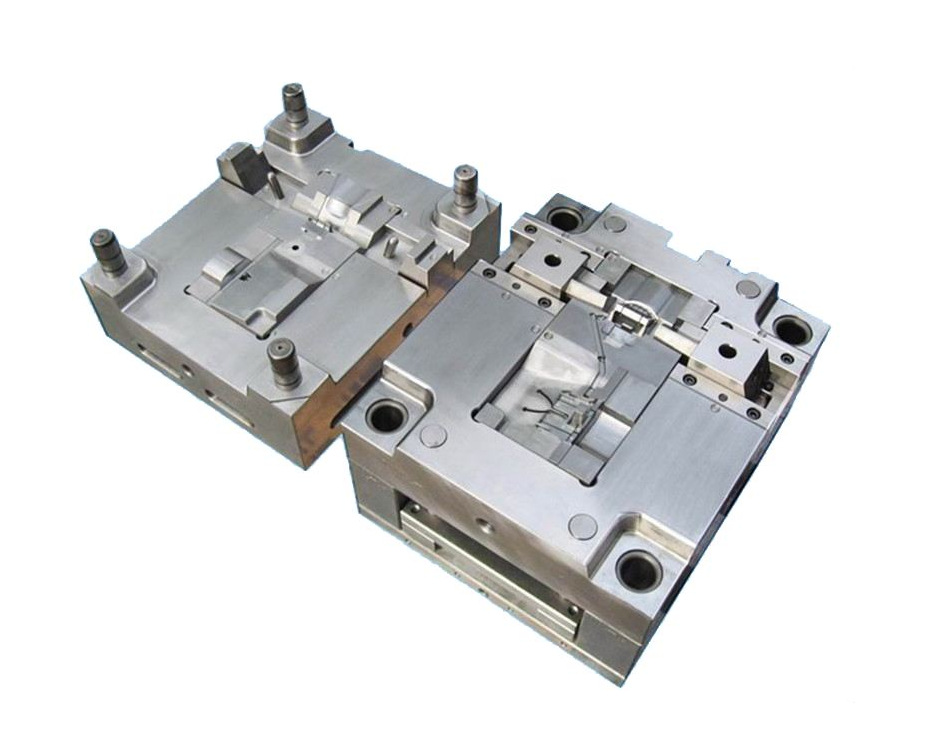

Custom injection molds are designed specifically for your unique part geometry, material requirements, and production volume. They offer significant advantages over standard molds, including the ability to produce complex shapes, incorporate multiple cavities for higher productivity, and achieve longer mold life for high-volume production runs.

Standard molds, on the other hand, are pre-made tooling that can only produce simple, generic parts. While they may seem more cost-effective initially, they often require significant modifications to work with custom designs, leading to higher overall costs and longer lead times.

Real-World Case Study

A US-based hardware startup recently approached us after experiencing significant delays with their initial mold supplier. They had chosen a low-cost standard mold option to save money, but the mold was unable to produce their complex plastic housing without significant defects. This required three separate mold modifications, costing them an additional $25,000 and delaying their product launch by 3 months. By investing in a custom injection mold tooling solution, they were able to achieve first-time success and get their product to market on schedule.

The Changing Procurement Mindset

We’re seeing a significant shift in how procurement teams approach injection mold sourcing. Instead of focusing solely on the initial mold price, buyers are now evaluating the total lifecycle cost and long-term value. This includes considering factors like mold life, maintenance requirements, modification costs, and production efficiency.

This change in perspective is being driven by three major trends that are transforming the custom injection mold manufacturing industry. Understanding these trends is essential for any procurement manager or engineer looking to make informed sourcing decisions.

Three Major Trends Transforming Custom Injection Mold Manufacturing

The Upgrade of Mold Clusters: Shifting to Engineering-Led Capabilities

China’s traditional mold manufacturing clusters, such as Huangyan and Dongguan, are undergoing a significant transformation. For decades, these regions were known primarily for their low-cost production capabilities, but today they are investing heavily in advanced equipment, automation, and engineering talent.

The Role of Mold Makers Is Evolving

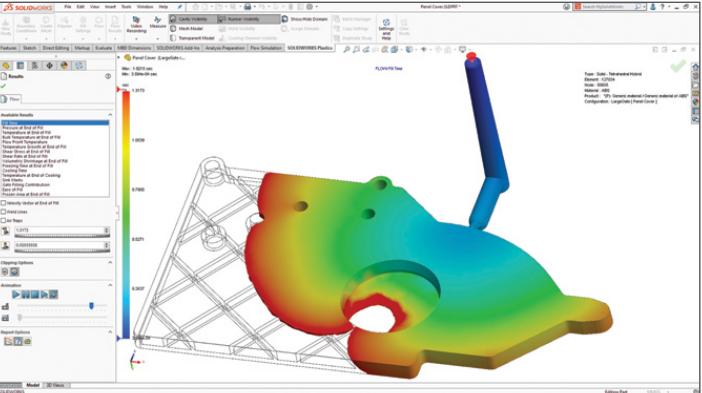

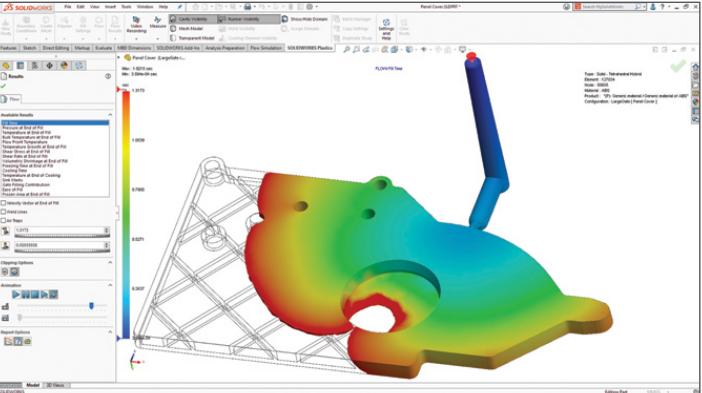

The biggest change is in the role of the mold maker. Traditionally, mold factories would simply build to print, following the customer’s design without providing any input or suggestions. Today, leading custom injection mold manufacturers are taking on a more consultative role, offering proactive design optimization, DFM (Design for Manufacturing) feedback, and mold flow analysis.

Benefits for Buyers

This shift to engineering-led capabilities offers significant benefits for B2B buyers:

- Faster Time-to-Market: Reduced design iterations and higher first-trial success rates

- Lower Project Risk: Proactive identification of potential issues before mold construction begins

- Better Part Quality: Optimized mold designs that produce consistent, high-quality parts

- Lower Total Cost: Reduced need for costly modifications and rework

This evolution is not just about technology—it’s about mindset. The best custom injection mold manufacturers now see themselves as product partners, not just suppliers. They invest in engineering talent and advanced analysis tools to help their customers succeed.

Digitalization and On-Demand Platforms Are Streamlining Mold Sourcing

The digital transformation of manufacturing is now reaching the custom injection mold industry. Online RFQ platforms, instant DFM feedback systems, and transparent quoting tools are making it easier than ever for B2B buyers to source high-quality mold tooling.

How Digital Platforms Are Changing the Game

These digital platforms are not replacing traditional mold manufacturers—they’re helping them work more efficiently. By automating routine tasks like quote generation and design analysis, these platforms allow mold makers to focus on what they do best: engineering high-quality tooling.

Key Features of Modern Mold Sourcing Platforms:

Instant DFM Feedback

AI-powered systems analyze CAD files and provide immediate design for manufacturing feedback, identifying potential issues and suggesting improvements.

Transparent Quoting

Breakdown of costs by component (steel, machining, polishing, etc.) and clear explanation of mold life expectations based on material selection.

Project Tracking

Real-time updates on mold progress, from design approval to machining, polishing, and trial runs.

Seamless Scaling

Support for prototype molds, bridge tooling, and production molds, with easy transition between stages as your product evolves.

Leading custom injection mold manufacturers in China have already embraced these digital tools, offering 24-48 hour DFM feedback and transparent quoting processes. This allows buyers to make more informed decisions and reduces the risk of miscommunication or unexpected costs.

Geopolitical and Tariff Changes Driving Diversification—and New Strengths

Geopolitical tensions and tariff changes have led many B2B buyers to re-evaluate their global sourcing strategies for custom injection mold tooling. While some companies have moved production to other countries, others have found that Chinese mold manufacturers offer unique advantages that are difficult to replicate elsewhere.

The Changing Face of Chinese Mold Manufacturing

Chinese custom injection mold manufacturers have evolved significantly in recent years. They are no longer just low-cost providers—they now offer world-class engineering capabilities, advanced equipment, and reliable delivery performance.

Key Advantages of Chinese Mold Manufacturers:

- Engineering Expertise: Deep experience in complex mold design and manufacturing for global markets

- Cost Competitiveness: While prices have risen, they remain competitive compared to Western manufacturers

- Speed: Faster lead times for complex molds due to concentrated supply chains and 24/7 production

- Quality: Investment in advanced equipment and quality control systems

- IP Protection: Improved intellectual property protection policies and procedures

Many international buyers have found that maintaining relationships with multiple mold suppliers in different regions provides the best balance of cost, quality, and risk mitigation. This approach allows them to take advantage of the unique strengths of each supplier while reducing their exposure to geopolitical risks.

What These Trends Really Mean for Procurement Managers and Engineers

How Evaluation Criteria for Injection Mold Suppliers Are Changing

The traditional approach to selecting injection mold suppliers is no longer sufficient in today’s rapidly evolving market. Buyers need to shift their focus from purely cost-based decisions to a more holistic evaluation that considers technical capabilities, engineering support, and long-term partnership potential.

This shift in evaluation criteria reflects the changing nature of manufacturing relationships. Today’s buyers need partners who can provide more than just production capabilities—they need strategic allies who can help them optimize their designs, reduce costs, and accelerate time-to-market.

5 Critical Capabilities Every Serious Buyer Should Demand

1. Strong Mold Design and DFM Expertise

Look for suppliers who provide proactive design optimization, not just build-to-print services. This includes mold flow analysis, gate location optimization, and material selection recommendations.

2. Precision Machining Capabilities

Invest in suppliers with high-speed CNC machines, EDM capabilities, and precision polishing equipment. These tools are essential for producing complex molds with tight tolerances.

3. Mold Life Estimation and Material Selection

A reliable partner should be able to accurately estimate mold life based on your production volume and material requirements, and recommend the appropriate steel grade and heat treatment.

4. Comprehensive Trial and Production Support

Look for suppliers who provide full trial support, including sample inspection reports, and can help you transfer production to your chosen manufacturing facility.

5. Clear Communication and Project Management

A reliable global partner should have fluent English communication skills, provide regular project updates, and have a structured project management process to ensure on-time delivery.

Leading custom injection mold manufacturers have already embraced these capabilities, positioning themselves as strategic partners rather than just suppliers. When evaluating potential partners, look for companies that can demonstrate these capabilities through case studies, client testimonials, and direct technical discussions.

Understanding the Real Cost Drivers of Custom Injection Molds

Understanding the factors that influence custom injection mold costs is essential for making informed procurement decisions. While the final price will depend on your specific requirements, there are several key cost drivers that every buyer should be aware of.

1. Mold Complexity

The complexity of your part geometry is one of the biggest factors affecting mold cost. Parts with complex shapes, undercuts, thin walls, or tight tolerances require more sophisticated mold designs and machining processes, which increases the overall cost.

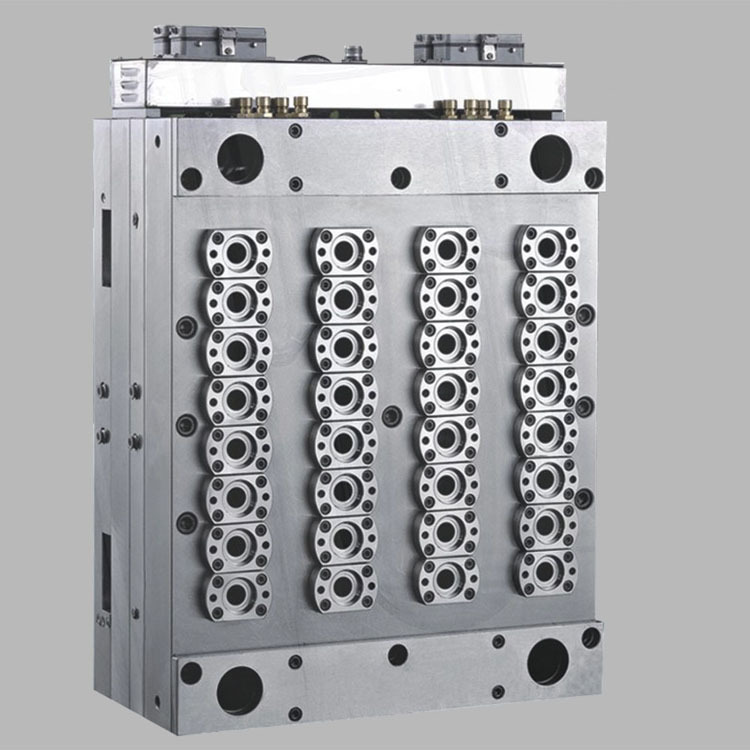

2. Cavity Count

The number of cavities in the mold directly impacts both the initial cost and the production efficiency. Multi-cavity molds allow you to produce multiple parts in each cycle, which reduces the per-part production cost but increases the initial mold investment.

3. Material Selection

The type of steel used for the mold significantly affects both the cost and the mold life. Hardened steels offer longer mold life but are more expensive to machine, while pre-hardened steels are more cost-effective but have a shorter lifespan.

4. Mold Life Requirements

The expected production volume will determine the required mold life. For high-volume production (millions of parts), you’ll need a mold made from hardened steel with proper heat treatment. For low-volume production, a less expensive pre-hardened steel may be sufficient.

5. Post-Launch Support and Maintenance

Don’t forget to consider the cost of post-launch support and maintenance. A higher-quality mold may cost more initially but will require less maintenance and have a lower risk of unexpected failures that can disrupt production.

Key Insight

While it may be tempting to choose the least expensive mold option, investing in a higher-quality custom injection mold can actually save you money in the long run. A well-designed mold will produce consistent, high-quality parts with minimal defects, reducing the need for costly modifications and rework.

A Practical Checklist for Selecting Your Custom Injection Mold Partner

To help you make an informed decision when selecting a custom injection mold partner, we’ve created a practical checklist that you can use during your evaluation process:

- Do they provide mold flow analysis and proactive DFM suggestions?

This is a critical indicator of their engineering capabilities and commitment to helping you optimize your design for manufacturability. - Can they support multiple trial rounds and rapid modifications?

Look for partners who have a proven process for handling design changes and modifications efficiently. - Do they have verified case studies in your industry?

Different industries have different requirements—make sure your partner understands the specific needs and standards of your industry. - Do they build to international export mold standards (DME/HASCO)?

This ensures that your mold will be compatible with injection molding machines around the world. - Can they commit to long-term production support and spare parts?

A reliable partner should be able to support you throughout the entire product lifecycle. - Do they have a structured project management process?

Clear communication and project management are essential for ensuring on-time delivery and quality. - Do they have proper IP protection measures in place?

Intellectual property protection is critical when working with international suppliers. - Can they provide references from clients with similar project requirements?

Client references are one of the best ways to verify a supplier’s capabilities and reliability.

By using this checklist during your supplier evaluation process, you can significantly reduce the risk of selecting a partner who may not be able to meet your specific needs. Remember, the goal is to find a long-term partner who can grow with your business and help you achieve your manufacturing goals.

Final Thoughts: Treat Your Injection Mold as a Long-Term Investment, Not a One-Time Purchase

The custom injection mold manufacturing industry is undergoing significant transformation, driven by advances in technology, changing buyer demands, and evolving global supply chains. As we look ahead to 2025–2026, it’s clear that the traditional approach to mold sourcing is no longer sufficient.

Today’s procurement managers and engineers need to adapt to these changes by re-evaluating their supplier selection criteria and looking for partners who can provide more than just production capabilities. The right custom injection mold manufacturer should be a strategic ally who can help you optimize your designs, reduce costs, and accelerate time-to-market.

By understanding the key trends shaping the industry—including the shift to engineering-led capabilities, the rise of digital sourcing platforms, and the changing global supply chain landscape—you can make more informed decisions when selecting a custom injection mold partner.

Ready to Get Started with Your Custom Injection Mold Project?

If you’re planning a new injection molding project and want a partner that combines advanced design, precision tooling, and reliable project management, we’re here to help.

Remember, your injection mold is not just a tool—it’s a long-term investment in the success of your product. By choosing a supplier that embraces the latest trends and technologies, you can position your business for success in the years ahead.

© 2025 Gold Cattle Manufacturing. All rights reserved.