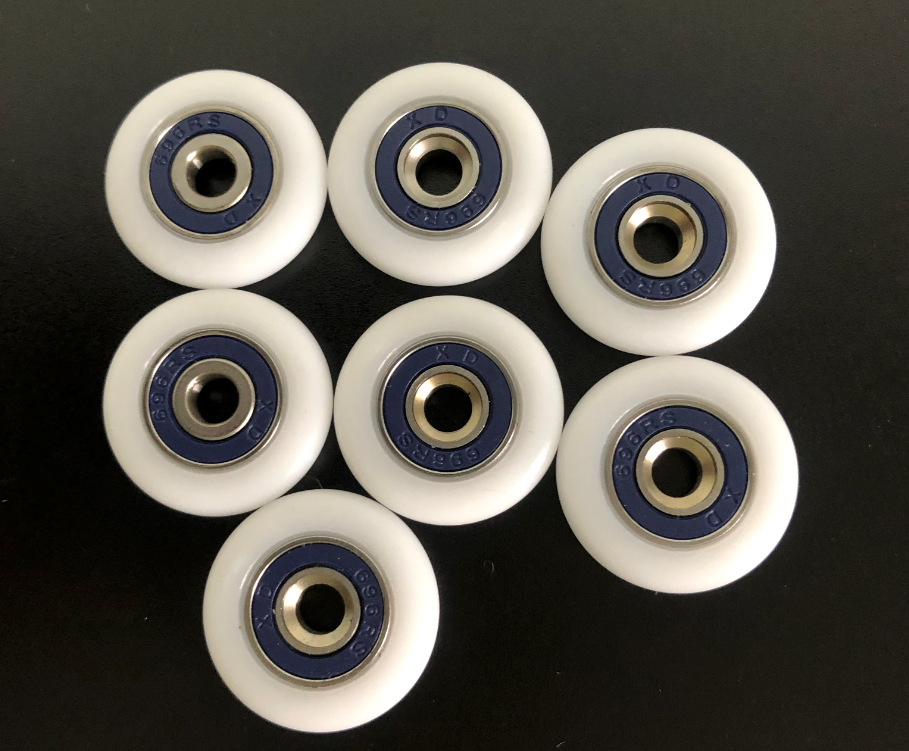

Polypropylene (PP) Material Characteristics

- Structural Rigidity: Shore hardness up to 85D+ for stable performance

- Load Capacity: 3-inch size supports 80kg+ static load capacity

- Chemical Resistance: Excellent resistance to acids, alkalis, and corrosive substances

- Cost Efficiency: Economical solution for high-volume production

- Application Areas: Industrial storage equipment, logistics trolleys, material handling

Thermoplastic Elastomer (TPE) Material Characteristics

- Elastic Performance: 70% rebound rate for superior shock absorption

- Noise Reduction: Operating noise as low as 42dB for quiet operation

- Wear Resistance: Less than 0.3mm tread wear after 100,000 cycle tests

- Eco-friendly Properties: Non-toxic and recyclable, meeting FDA standards

- Application Areas: Medical equipment, smart home devices, premium appliances

Polyoxymethylene (POM) Material Characteristics

- Self-lubrication: Low friction coefficient requiring no additional lubrication

- Dimensional Stability: Low shrinkage rate for consistent performance

- Mechanical Strength: High strength and rigidity for structural integrity

- Fatigue Resistance: Maintains shape through repeated cycles of use

- Application Areas: Precision transmission systems, high-end equipment

Polyamide (PA) Material Characteristics

- Wear Performance: Exceptional wear resistance for extended service life

- Temperature Range: Wide operating range from -40°C to 120°C

- Load Capacity: High strength construction for heavy-duty applications

- Modification Potential: Can be reinforced with glass fiber for enhanced performance

- Application Areas: Industrial casters, mechanical equipment, heavy machinery

Material Selection Decision Matrix

|

Application Scenario

|

Recommended Material

|

Key Performance Metrics

|

Cost Index

|

|

Industrial Storage

|

PP

|

80kg+ load capacity, chemical resistance

|

Low

|

|

Medical Equipment

|

TPE

|

≤45dB noise level, eco-friendly

|

High

|

|

Precision Transmission

|

POM

|

0.15 friction coefficient, dimensional stability

|

High

|

|

Heavy Equipment

|

PA

|

100MPa+ strength, 100,000 cycle wear resistance

|

Medium

|

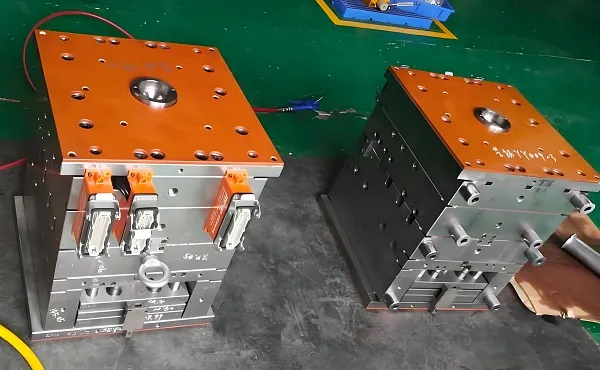

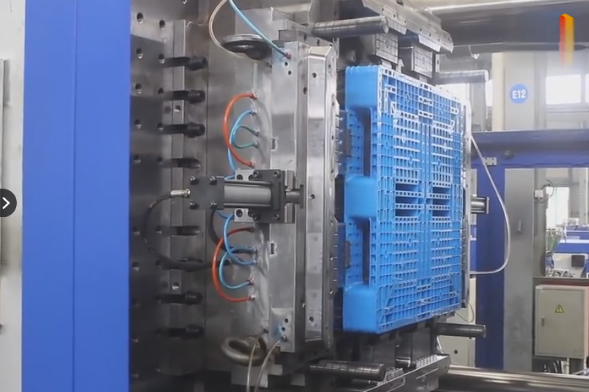

Precision Injection Molding Technology

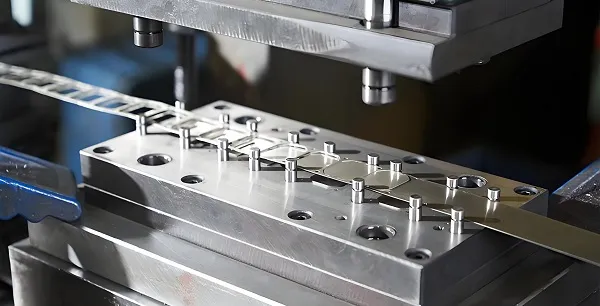

Mold Engineering Design

Cavity System Optimization

- Multi-cavity Layout: Optimized for production efficiency and cost-effectiveness

- Symmetrical Structure: Balanced injection pressure distribution for consistent quality

- Conformal Cooling: Water channels precisely following cavity contours

- Ejection System: Specialized ejection mechanisms to protect wheel surface precision

Gating System Design

- Hot Runner Technology: Reduces material waste by 15-20%, lowering production costs

- Gate Optimization: Non-visible surface gating to preserve aesthetic quality

- Runner Balancing: Optimized flow path design ensuring uniform filling

- Ventilation System: Effective gas evacuation to prevent bubble defects

Injection Process Parameter Control

Temperature Management System

- Barrel Temperature: 170-200°C (adjusted according to material properties)

- Mold Temperature: 40-80°C (ensuring dimensional stability)

- Nozzle Temperature: 5-10°C lower than barrel temperature

- Temperature Precision: Fluctuation controlled within ±1°C

Pressure Control System

- Injection Pressure: 80-120MPa (adjusted based on product complexity)

- Holding Pressure: 50-70% of injection pressure

- Back Pressure Control: 2-5MPa (ensuring melt homogeneity)

- Pressure Stability: Real-time monitoring and dynamic adjustment

Time Parameter Optimization

- Injection Time: 1-3 seconds (rapid cavity filling)

- Holding Time: 5-15 seconds (compensation for shrinkage)

- Cooling Time: 10-30 seconds (adjusted based on product thickness)

- Cycle Optimization: Balancing production efficiency and product quality

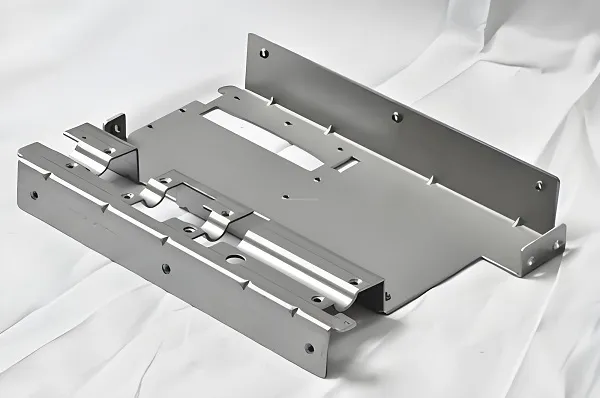

Customization Service Process

Requirements Analysis and Solution Design

- Application Assessment: In-depth understanding of operating environment and working conditions

- Performance Requirements: Load capacity, wear resistance, noise reduction specifications

- Technical Specifications: Dimensional accuracy, mounting configuration, material selection

- Budget Planning: Production volume, quality requirements, delivery timeline

Product Development and Validation

- 3D Digital Design: Precision modeling using professional CAD software

- DFM Analysis: Design-for-manufacturability evaluation to ensure production feasibility

- Rapid Prototyping: 3D printed samples for design verification

- Performance Testing: Material property and structural strength validation

Mold Manufacturing and Debugging

- High-precision Mold Making: CNC machining with ±0.005mm dimensional tolerance

- Surface Treatment: Polishing and chrome plating to enhance mold release properties

- Trial Production: Process parameter optimization for quality assurance

- Mold Validation: Small-batch production verification

Mass Production and Delivery

- Production Planning: Optimized scheduling and resource allocation

- Quality Control: First article inspection, process monitoring, final quality checks

- Packaging Logistics: Protective packaging and optimized distribution

- After-sales Support: Quality tracking, technical assistance, continuous improvement

Comprehensive Quality Control

Raw Material Quality Control

- Material Inspection: Purity analysis, performance testing, batch traceability

- Drying Treatment: 80-120°C preheating for 2-4 hours, moisture content <0.05%

- Storage Management: Climate-controlled environment with humidity and dust protection

- Quality Documentation: Comprehensive raw material quality records

Production Process Monitoring

- Equipment Status Monitoring: Real-time parameter tracking and adjustment

- Process Parameter Control: Precise regulation of temperature, pressure, and timing

- In-process Inspection: Sampling every 100 cycles for timely parameter adjustment

- Exception Handling: Rapid response and resolution protocols for production issues

Finished Product Quality Testing

- Dimensional Accuracy: Coordinate measuring machine with ±0.001mm precision

- Visual Inspection: Surface defect detection and color consistency verification

- Performance Testing: Load testing, wear resistance evaluation, noise measurement

- Reliability Validation: Lifespan testing and environmental adaptability assessment

Quality Assurance System

- ISO9001 Certification: International quality management system accreditation

- SGS Testing: Third-party verification by globally recognized testing authority

- RoHS Compliance: Environmentally friendly materials meeting international standards

- Continuous Improvement: Data-driven quality optimization framework

Performance Testing and Application Validation

Key Performance Indicator Testing

Mechanical Performance Testing

- Load Capacity: Static and dynamic load testing under various conditions

- Impact Resistance: Drop weight impact testing simulating real-world scenarios

- Fatigue Life: Cyclic loading testing to validate long-term performance

- Wear Resistance: Friction and wear testing to evaluate service life

Environmental Adaptability Testing

- Temperature Range: Thermal cycling from -40°C to 120°C

- Humidity Effects: Performance evaluation under high humidity conditions

- Chemical Resistance: Immersion testing in various chemical solutions

- UV Aging: Outdoor environment ultraviolet exposure testing

Operational Performance Testing

- Noise Reduction: Acoustic measurements on different flooring materials

- Rolling Resistance: Friction testing under various load conditions

- Mounting Compatibility: Fit testing with diverse equipment configurations

- Safety Performance: Anti-slip and anti-loosening safety verification

Typical Application Scenario Validation

Industrial Storage Equipment

- Shelving Casters: 500kg+ load capacity with chemical resistance

- Logistics Trolleys: Quiet operation suitable for warehouse environments

- Automation Equipment: High precision with low friction coefficient

- Cleaning Equipment: Chemical-resistant and easy-to-clean surfaces

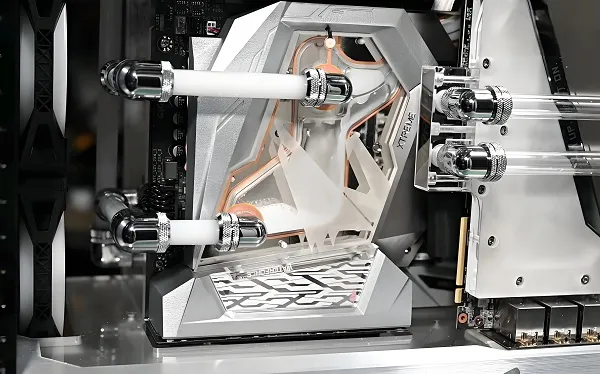

Medical Equipment

- Hospital Bed Casters: ≤45dB noise level with excellent shock absorption

- Diagnostic Equipment: High precision with stability requirements

- Caregiving Devices: Eco-friendly materials meeting medical standards

- Mobile Equipment: Smooth maneuverability with easy operation

Smart Home Products

- Furniture Casters: Floor protection with quiet operation

- Storage Solutions: Lightweight construction with easy maneuverability

- Kitchen Appliances: Heat-resistant and easy-to-clean surfaces

- Office Furniture: Aesthetic appeal with durable performance

Xiamen Goldcattle Technical Service System

Technical Strength Demonstration

Core Technical Advantages

- 26 Years Experience: Deep industry expertise and technical accumulation

- 100+ Advanced Equipment: Internationally leading processing machinery and testing instruments

- ±0.005mm Precision: Ultra-high precision manufacturing capabilities

- National High-tech Enterprise: Technology innovation and R&D capability certification

Service System Assurance

- One-stop Solutions: Comprehensive services from design through production

- Rapid Response: 7×24 technical support and service availability

- Stringent Quality Control: Comprehensive quality management system

- Customized Solutions: Tailored approaches meeting specific requirements

Professional Service Offerings

- Mold Design and Manufacturing: Precision tooling design and fabrication services

- Injection Molding: High-precision plastic injection molding with quality control

- Surface Treatment: Spraying, plating, printing, and finishing processes

- Assembly and Testing: Final product assembly and performance validation

Successful Application Cases

- Industrial Automation: Heavy-duty plastic wheel solutions for major manufacturers

- Medical Equipment: Quiet, shock-absorbing wheels for medical devices

- Smart Home: Custom wheel components for premium household appliances

- Precision Instruments: High-precision plastic wheels for transmission systems

Why Choose Xiamen Goldcattle?

- Industry-leading injection molding technology

- Core capabilities in precision mold manufacturing

- Rigorous quality control systems

- Continuous investment in technological innovation

- Rapid response from professional engineering team

- Transparent project progress management

- Comprehensive after-sales support system

- Flexible collaboration model options

- Internationally standardized product quality

- On-time delivery reputation guarantee

- Cost-optimized solution engineering

- Long-term stable partnership development

Contact Us Today for Your Custom Solution

- Company Name: Xiamen Goldcattle Plastic & Metal Products Co., Ltd.

- Website: www.xmgoldcattle.com