ABS Material Characteristics

- Comprehensive Performance: High strength, good toughness, dimensional stability

- Processing Performance: Easy injection molding with high surface finish

- Cost Advantage: Economical solution for high-volume production

- Safety Certification: Meets EN71, ASTM F963 international standards

- Application Areas: Building block toys, model cars, doll main structures

PVC Material Characteristics

- Plasticity: Adjustable hardness to meet different application requirements

- Chemical Resistance: Resistant to acids, alkalis, and corrosion with long service life

- Environmental Certification: Complies with RoHS, REACH environmental standards

- Cost Efficiency: Moderate price with good cost-performance ratio

- Application Areas: Vinyl toys, soft rubber accessories, figurine models

TPE Material Characteristics

- Elastic Performance: Shore hardness adjustable from 0A-100A with soft touch

- Safety and Environmental Protection: Non-toxic, tasteless, meets food contact standards

- Sound Insulation Performance: High vibration damping coefficient with low noise

- Weather Resistance: Wide temperature range from -60°C to 120°C

- Application Areas: Infant toys, educational toys, interactive toys

PP Material Characteristics

- Lightweight Properties: Low density and light weight

- Environmental and Non-toxic: Meets FDA food contact standards

- Impact Resistance: Good toughness and not easily broken

- Cost Advantage: Low price and economical

- Application Areas: Children’s toys, outdoor toys, disposable toys

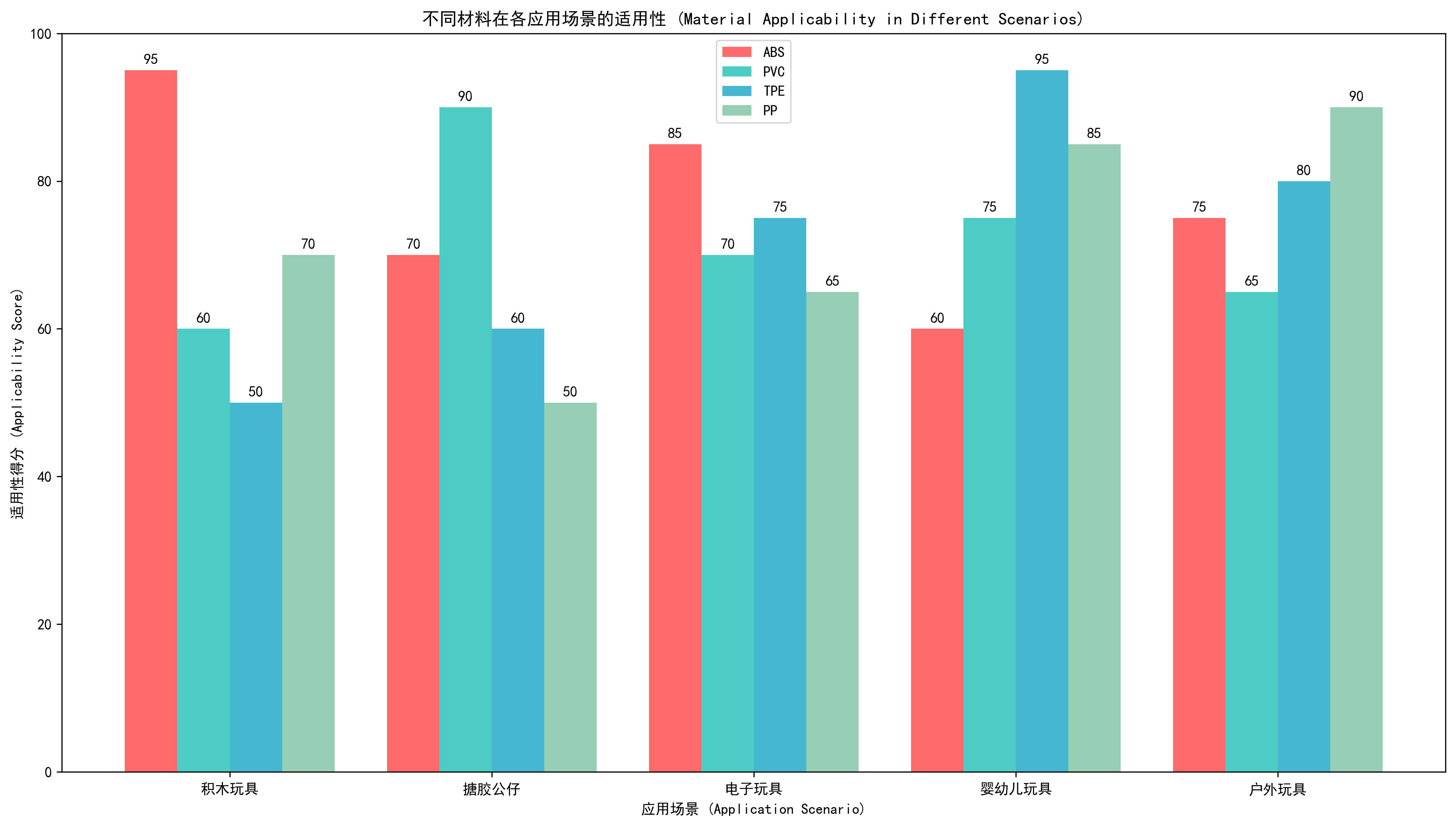

Material Selection Decision Matrix

|

Application Scenario

|

Recommended Material

|

Key Performance Metrics

|

Cost Index

|

|

Building Block Toys

|

ABS

|

High strength, dimensional accuracy ±0.05mm

|

Medium

|

|

Vinyl Figurines

|

PVC

|

Strong plasticity, smooth surface

|

Low

|

|

Infant Toys

|

TPE

|

Soft and safe, non-toxic and tasteless

|

High

|

|

Outdoor Toys

|

PP

|

Good weather resistance, low cost

|

Low

|

|

High-end Models

|

ABS+PC

|

High strength, high gloss

|

High

|

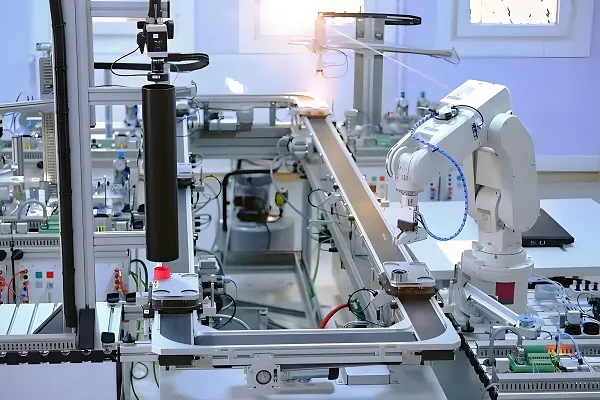

Precision Injection Molding Technology

Mold Engineering Design

Cavity System Optimization

- Multi-cavity Layout: One-mold multi-cavity design to improve production efficiency

- Symmetrical Structure: Balanced injection pressure distribution to ensure molding quality

- Cooling System: Conformal cooling channels with precise temperature control

- Ejection System: Specialized ejection mechanisms to protect toy surface quality

Gating System Design

- Hot Runner Technology: Reduces waste by 15-20%, lowering production costs

- Gate Optimization: Non-visible surface feeding to avoid affecting product aesthetics

- Runner Balancing: Optimized runner design ensuring uniform filling

- Ventilation System: Effective gas evacuation to prevent bubble defects

Injection Process Parameter Control

Temperature Management System

- Barrel Temperature: 180-220°C (adjusted according to material properties)

- Mold Temperature: 40-80°C (ensuring dimensional stability)

- Nozzle Temperature: 5-10°C lower than barrel temperature

- Temperature Precision: Fluctuation controlled within ±1°C

Pressure Control System

- Injection Pressure: 80-130MPa (adjusted based on product complexity)

- Holding Pressure: 50-70% of injection pressure

- Back Pressure Control: 2-5MPa (ensuring melt homogeneity)

- Pressure Stability: Real-time monitoring and dynamic adjustment

Time Parameter Optimization

- Injection Time: 1-5 seconds (rapid cavity filling)

- Holding Time: 5-20 seconds (compensation for shrinkage)

- Cooling Time: 10-40 seconds (adjusted based on product thickness)

- Cycle Optimization: Balancing production efficiency and product quality

Surface Treatment Technology

- Spraying Process: Environmentally friendly coatings with bright and durable colors

- Pad Printing Technology: Fine pattern printing with precise positioning

- Screen Printing Process: Large-area pattern printing with low cost

- Electroplating Treatment: Metal texture enhancing product quality

- UV Coating: High gloss with wear and scratch resistance

Customization Service Process

Requirements Analysis and Solution Design

- Product Positioning: Clarify toy type, target age, functional requirements

- Design Concept: 3D modeling, appearance design, functional planning

- Material Selection: Choose appropriate materials based on application scenarios

- Cost Budget: Batch size, quality requirements, delivery timeline

Product Development and Validation

- 3D Digital Design: Precision modeling using professional CAD software

- DFM Analysis: Design-for-manufacturability evaluation to optimize design solutions

- Rapid Prototyping: 3D printed samples to verify design concepts

- Functional Testing: Structural strength, safety, and playability testing

Mold Manufacturing and Debugging

- Mold Design: Cavity layout, gating system, cooling system design

- CNC Machining: High-precision processing with dimensional tolerance ±0.005mm

- Surface Treatment: Polishing and chrome plating to enhance mold release

- Trial Production: Optimize injection parameters to ensure molding quality

Mass Production and Delivery

- Production Planning: Reasonable arrangement of production schedule and resource allocation

- Quality Monitoring: First article inspection, process control, final inspection

- Packaging and Logistics: Safe packaging and optimized distribution

- After-sales Service: Quality tracking, technical support, continuous improvement

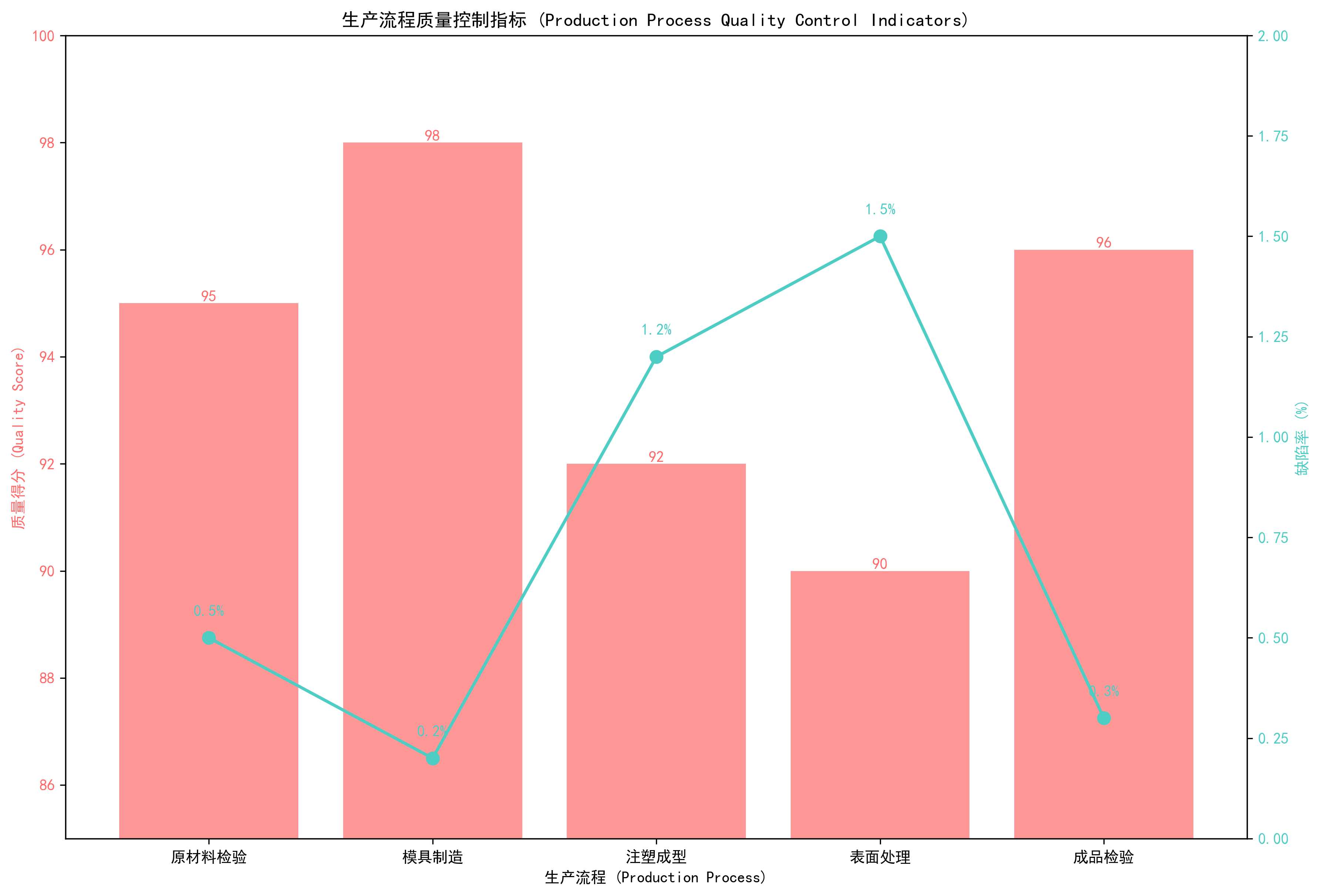

Comprehensive Quality Control

Raw Material Quality Control

- Material Inspection: Purity analysis, performance testing, batch traceability

- Drying Treatment: 80-100°C preheating for 2-4 hours, moisture content <0.05%

- Storage Management: Moisture-proof, dust-proof, temperature-controlled environment

- Quality Documentation: Complete raw material quality records

Production Process Monitoring

- Equipment Status Monitoring: Real-time monitoring and adjustment of injection machine parameters

- Process Parameter Control: Precise control of temperature, pressure, and timing

- In-process Inspection: Sampling every 100 cycles for timely parameter adjustment

- Exception Handling: Rapid response and resolution of production anomalies

Finished Product Quality Testing

- Dimensional Accuracy Testing: Coordinate measuring machine with precision ±0.001mm

- Visual Quality Inspection: Surface defect and color consistency detection

- Performance Testing: Strength testing, wear resistance testing, safety testing

- Reliability Validation: Lifespan testing and environmental adaptability testing

Safety Certification System

- EN71 Certification: European Union toy safety standard

- ASTM F963 Certification: American toy safety standard

- ISO8124 Certification: International toy safety standard

- 3C Certification: China Compulsory Product Certification

- CE Certification: European Union product safety certification

Performance Testing and Safety Validation

Key Performance Indicator Testing

Mechanical Performance Testing

- Strength Testing: Compressive strength, tensile strength, flexural strength

- Impact Testing: Drop weight impact, pendulum impact testing

- Wear Testing: Friction and wear testing to evaluate service life

- Fatigue Testing: Cyclic loading testing to validate long-term performance

Safety Performance Testing

- Toxicity Testing: Heavy metal content, hazardous substance detection

- Flame Retardant Testing: Combustion performance, smoke density testing

- Electrical Safety: Electrical safety testing for electronic toys

- Chemical Safety: Hazardous substance migration testing

Usage Performance Testing

- Playability Testing: Functional integrity, operational convenience

- Durability Testing: Service life, maintenance costs

- Educational Value: Cognitive development, skill training assessment

- Market Acceptance: User experience, satisfaction survey

Typical Application Scenario Validation

Building Block Toys

- Assembly Precision: Bump and groove 配合精度 ±0.05mm

- Load Capacity: Single block can withstand 10kg weight

- Safety Design: Rounded corner treatment to avoid scratching children

- Environmental Materials: Non-toxic and tasteless, meets food contact standards

Vinyl Figurines

- Surface Smoothness: Ra ≤ 0.8μm for comfortable touch

- Color Vividness: Color saturation ≥ 95%, long-lasting without fading

- Safety Performance: No sharp edges, meets safety standards

- Collectible Value: Exquisite details and craftsmanship

Electronic Toys

- Functional Integrity: All functions working properly

- Battery Safety: Safe and reliable battery compartment design

- Electromagnetic Compatibility: Meets EMC standards with no interference

- Water and Dust Resistance: IP rating testing for various environments

Xiamen Goldcattle Technical Service System

Technical Strength Demonstration

Core Technical Advantages

- 26 Years Professional Experience: Deep industry accumulation and technical expertise

- 100+ Advanced Equipment: Internationally leading processing equipment and testing instruments

- ±0.005mm Precision: Ultra-high precision processing capability meeting precision requirements

- National High-tech Enterprise: Technology innovation capability and R&D strength certification

Service System Assurance

- One-stop Solution: Comprehensive services from design to production

- Rapid Response Mechanism: 7×24 hour technical support and service response

- Strict Quality Control: Complete quality management system and testing processes

- Customized Services: Personalized solutions based on customer needs

Professional Service Offerings

- Mold Design and Manufacturing: High-precision mold design and manufacturing services

- Injection Molding Processing: Precision injection molding and quality control

- Surface Treatment Processes: Spraying, pad printing, screen printing, electroplating and other surface treatments

- Product Assembly and Testing: Finished product assembly and performance testing validation

Successful Application Cases

- Well-known Building Block Brands: Custom services for international well-known building block brands

- Anime IP Figurines: Custom vinyl figurines for popular anime characters

- Educational Toys: Children’s educational puzzle toy development

- Electronic Toys: Smart interactive toy accessory customization

Start Your Customization Journey

Why Choose Xiamen Goldcattle?

- Industry-leading injection molding technology

- Core capabilities in precision mold manufacturing

- Strict quality control systems

- Continuous investment in technological innovation

- Rapid response from professional engineering team

- Transparent project progress management

- Comprehensive after-sales support system

- Flexible collaboration model options

- Internationally standardized product quality

- On-time delivery reputation guarantee

- Cost-optimized solution engineering

- Long-term stable partnership development

Contact Us Today for Your Custom Solution

- Company Name: Xiamen Goldcattle Precision Manufacturing Co., Ltd.

- Official Website: www.xmgoldcattle.com