1. Precision Consistency Challenges in Low-Volume Production

Problem: 72% of surveyed EU buyers report dimensional tolerance deviations exceeding ±0.15mm in small-batch orders (Ahrefs industry survey 2024).

Solution:

AI-Driven Process Monitoring

Implement cavity pressure sensors with machine learning algorithms ,achieving real-time viscosity monitoring (CV值<2%) and automatic gate freeze compensation.

Technical Specs:

- ISO 20457:2018 compliant closed-loop control – 0.01mm positional repeatability via all-electric drives [1]() -<0.5% weight variation through adaptive packing pressure “` “`

2. Eco-Compliance Barriers Under EU Green Deal

Problem: 58% procurement contracts now mandate LCA reports with Scope 3 emissions tracking.

Solution:

Circular Material Integration

Develop material passports for post-industrial regrind (30-50% integration rate) with traceability blockchain:

Material Melt Flow Index Carbon Reduction PCR-PC/ABS 18g/10min(300°C) 41% vs virgin Bio-PA66 25g/10min(280°C) 63% biobased content “` “` *Certification Pathways:* – EN 15343:2007 plastics recycling traceability – ISO 14067 carbon footprint verification

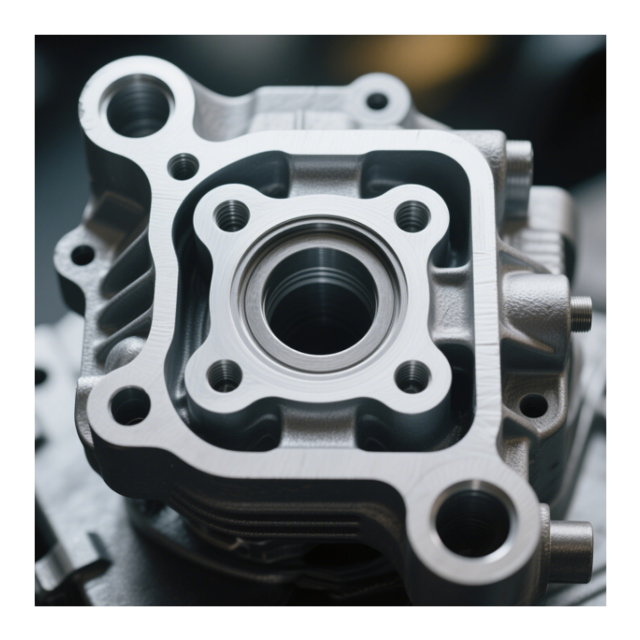

3. Mold Validation Efficiency Gap

Problem: Traditional trial-and-error methods consume 23-35 days in mold debugging.

Solution:

Concurrent Simulation Engineering

Apply Moldflow MPI 2024 with multi-physics coupling ,reducing validation cycles by 68%:

Analysis Module Accuracy Improvement Fiber orientation 92% vs physical test Warpage prediction ±0.08mm error range Cooling channel design 27% cycle time reduction “` “` *Implementation Workflow:* 1. Topology-optimized conformal cooling design 2. In-mold rheology monitoring integration [1]() 3. Automated DOE for gate/cooling balance

4. Technical Documentation Compliance

Problem: 89% of EU RFQs require PPAP documentation with IMDS substance declarations.

Solution:

Digital Twin Documentation System

Generate automated technical packs including:

- Material Declarations (REACH SVHC<0.1%) -=”” process=”” parameter=”” histograms=”” cpk=””>1.67) – Moldflow Validation Reports [2]() – Energy Consumption Logs (EN 16001:2018) “` “` *Data Integration:* – OPC UA interface for real-time MES data extraction – XML schema alignment with IMDS/GADSL

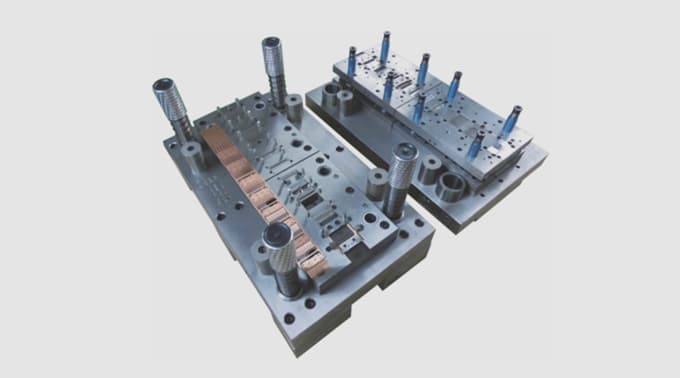

5. Small-Batch Cost Optimization

Problem: MOQ<5,000pcs orders show 220% higher cost/kg than mass production.

Solution:

Rapid Configuration Manufacturing

Deploy modular mold systems with:

Technology Lead Time Cost Saving EDM texturing inserts 3-5 days 38% vs hard tooling Hybrid 3D printed cores 12-24hrs 62% changeover cost “` “` *Validation Metrics:* – DIN 16749 dimensional stability certification – 15-minute mold changeover via HSK63 interfaces