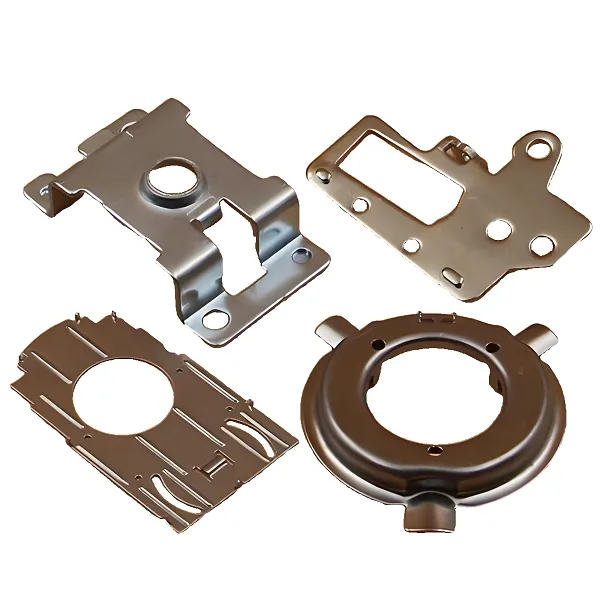

In the highly competitive manufacturing market, Xiamen Goldcattle has become a trusted partner of many companies with its excellent custom injection toolinging business. As a high-tech enterprise integrating R&D, design and manufacturing, Xiamen Goldcattle not only owns advanced production equipments and technical team, but also has won wide praise in the market for its high quality, high efficiency and customized service.

1.Technical strength and equipment advantages

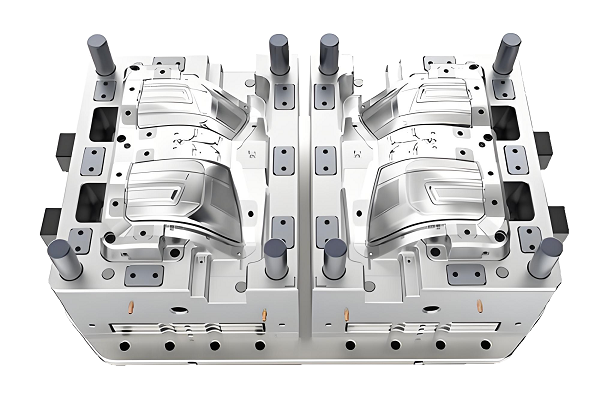

Xiamen Goldcattle has industry-leading injection tooling design and manufacturing capabilities, equipped with a series of high-precision processing equipment and testing equipment, to ensure that the precision and stability of the molds to reach the international advanced level. The company’s technical team consists of a group of experienced engineers and designers, who have profound professional knowledge and rich practical experience, and are able to provide customers with a full range of solutions from conceptual design to finished product delivery.

2.Customized service and innovation ability

We understand that every client’s needs are unique, so Xiamen Goldcattle pays special attention to customized services. Whether it is a complex structural design or special material requirements, we can customize production according to the specific needs of our customers. At the same time, we have an innovative R&D team that constantly explores new technologies and processes, and is committed to providing our customers with more advanced, efficient and environmentally friendly injection toolinging solutions.

Production Technology Preparation

Mold design: CAD (Computer Aided Design) software is used to carry out three-dimensional design of the mold to ensure that the mold structure is reasonable and the accuracy is up to standard. When designing, we need to consider various factors such as product material, size, wall thickness, cooling system, gate position, etc. to meet the specific needs of customers.

Process planning: According to the result of mold design, prepare detailed technical documents, including material selection, processing procedures, assembly and debugging programs. At the same time, the formulation of material quota and processing time quota, as well as the preliminary estimation of mold cost.

Material selection and purchase

Material selection: According to the design requirements of the mold and the use of the environment, select the appropriate mold materials, such as steel, aluminum, copper alloy, etc.. Material selection should take into account the strength, hardness, wear resistance, corrosion resistance and cost of the mold.

Material procurement: Communicate with suppliers to confirm the material specifications, quality and delivery date to ensure that the materials purchased meet the design requirements.

Processing and Manufacturing

Rough machining: Use CNC (Computer Numerical Control) machine tools to perform rough machining of mold parts, such as milling, drilling, etc., to form basic shapes and sizes.

Finishing: The roughly machined parts are subjected to finishing processes, including grinding, polishing, etc., in order to improve the accuracy and surface quality of the parts. For parts with fine and complex shapes, electric discharge machining (EDM) and wire EDM (WEDM) techniques can be used.

Heat treatment: According to the material characteristics and use requirements, heat treatment of mold parts, such as quenching, tempering, etc., in order to improve the hardness and wear resistance of the parts.

Marking and engraving: Use laser marking technology to make necessary markings and engravings on the molds for easy identification and management.

● Assembly and Commissioning

Assembling: The processed mold parts are assembled, including the moving mold, fixed mold, pouring system, cooling system and other parts. In the process of assembling, it is necessary to ensure that the matching precision and clearance between the parts are correctly adjusted.

Debugging: Install the mold on the injection toolinging machine for trial molding, observe the molding effect of the product, including size, appearance, defects and other aspects. Adjust the mold and injection parameters, such as temperature, pressure, time, etc., according to the results of the trial mold to optimize production efficiency and product quality.

●Mold trial and appraisal

Mold trial: Several mold trials are conducted before formal production to verify the design and manufacturing quality of the mold. During the trial molding process, we need to pay close attention to the molding of the product and the operation status of the mold.

Appraisal: Appraisal of the results of the trial mold to assess whether the mold can meet the expected functional requirements and quality standards. If there is any problem, adjustment and improvement should be made in time.

Mass production and maintenance

Mass production: After successful trial molding, the mold enters the mass production stage. The molten plastic is injected into the mold through the injection toolinging machine, and the mold is opened and the product is removed after cooling. During the production process, it is necessary to monitor the performance of the mold and product quality, and make timely adjustments to ensure the stability and consistency of production.

Mold Maintenance and Repair: Regular cleaning, lubrication and inspection of the molds are required to prolong the life of the molds and to ensure stability and product quality during the production process. For the discovery of wear and tear or damaged parts need to be replaced or repaired in a timely manner.

3.Quality Assurance and Efficient Production

Quality is the lifeline of Xiamen Goldcattle. We have established a strict quality management system, from raw material purchasing, production and processing to finished product inspection, each link is strictly controlled to ensure that each product meets customer requirements and industry standards. In addition, we have an efficient production process and management system, which enables us to ensure quality while realizing fast delivery to meet customers’ urgent needs.

4.Market Recognition and Performance Data

With excellent product quality and service quality, Xiamen Goldcattle has won wide recognition and praise in the market. Our customers are located in many countries and regions around the world, covering a wide range of industries such as automotive, home appliances, medical, electronics and so on. In recent years, our annual turnover has continued to grow and has exceeded the 50 million dollars mark. At the same time, we have also established long-term and stable cooperative relationships with many well-known enterprises, providing them with high-quality injection tooling products and services.

5.Future outlook and development plan

Looking into the future, Xiamen Goldcattle will continue to uphold the service concept of “high quality, high efficiency, high customization”, and constantly improve its technical strength and service level. We will increase the investment in research and development to explore more new technologies and processes; at the same time, we will strengthen the communication and cooperation with customers to understand their needs and expectations; in addition, we will actively expand domestic and international markets to seek more opportunities for cooperation and development space.

Customized injection tooling FAQ

●What is the lead time for custom injection tooling?

Answer: Xiamen Goldcattle’s custom injection tooling lead time varies from project to project, and usually depends on factors such as the complexity of the mold, material procurement lead time, and production arrangements. Generally speaking, we will fully communicate with our customers to set up a reasonable schedule and try our best to complete the customization and delivery of the molds within the agreed time. For specific lead time, please consult our sales or customer service staff.

●How to provide after-sales service?

Answer: Xiamen Goldcattle attaches great importance to after-sales service, we provide customers with the following after-sales service support:

Continuous Improvement: According to customers’ feedback and demands, we continuously optimize the design and manufacturing process of the molds to improve the performance and stability of the molds.

Long-term cooperation: Establish long-term and stable cooperation relationship with customers.