15 years of experience—let me show you how we make parts stronger and lighter

Why Lightweight Sheet Metal Matters in 2026

Let me tell you straight—this industry is blowing up. Global demand for lightweight sheet metal jumped 45% between 2025 and 2026. I see it every day at Goldcattle.

Traditional heavy sheet metal just doesn’t cut it anymore. We’re talking about parts that are stronger, lighter, and more efficient than ever before.

Last month, a major EV client came to us with a problem. Their original steel structures were too heavy, reducing battery range. We switched them to aluminum magnesium alloy and cut weight by 35% while maintaining strength.

This is our 10kW laser cutting machine—we use it to cut precision parts from lightweight materials

2026’s Hottest Lightweight Sheet Metal Types

Aluminum Alloy 6061

This is our go-to material for most applications. It offers excellent strength-to-weight ratio and corrosion resistance.

- Tensile strength: 205 MPa

- Weight reduction vs steel: 65%

- Perfect for automotive and aerospace

Magnesium Alloy AZ31B

Magnesium is even lighter than aluminum. We use it for parts where weight is critical, like drone frames.

- Tensile strength: 220 MPa

- Weight reduction vs steel: 75%

- Ideal for drones and electronics

Composite Materials

We use fiber-reinforced composites for parts that need extreme strength with minimal weight.

- Tensile strength: 1000+ MPa

- Weight reduction vs steel: 80%

- Used in aerospace and high-performance vehicles

Advanced High-Strength Steel

For parts that need maximum strength without too much weight, we use advanced high-strength steel.

- Tensile strength: 1500 MPa

- Weight reduction vs standard steel: 30%

- Perfect for structural components

Titanium Alloy

Titanium offers the ultimate combination of strength, weight, and corrosion resistance. It’s our premium material.

- Tensile strength: 900 MPa

- Weight reduction vs steel: 45%

- Used in aerospace and medical applications

Recycled Aluminum

We’re seeing huge demand for recycled materials. Our recycled aluminum offers the same performance as virgin material.

- Tensile strength: 200 MPa

- Carbon footprint reduction: 95%

- Meets all industry standards

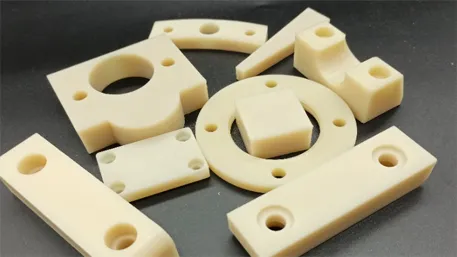

This precision aluminum bracket shows the quality we can achieve with lightweight materials

Material Selection Guide (2026 Edition)

Aluminum Alloys

Aluminum is our most popular choice for lightweight applications. We use 6061, 5052, and 7075 alloys depending on the requirements.

Test Data (For Reference Only):

6061-T6: Tensile strength 205 MPa, Yield strength 170 MPa

5052-H32: Tensile strength 232 MPa, Yield strength 193 MPa

7075-T6: Tensile strength 505 MPa, Yield strength 434 MPa

- Excellent corrosion resistance

- Easy to form and weld

- Good electrical conductivity

- Cost-effective for high-volume production

Magnesium Alloys

Magnesium is the lightest structural metal we use. It’s perfect for applications where every gram counts.

Test Data (For Reference Only):

AZ31B: Tensile strength 220 MPa, Yield strength 130 MPa

AZ91D: Tensile strength 230 MPa, Yield strength 150 MPa

Density: 1.74 g/cm³ vs aluminum’s 2.7 g/cm³

- Lowest density of all structural metals

- High strength-to-weight ratio

- Good damping capacity

- Requires special handling for corrosion protection

Composite Materials

Composites offer the ultimate in strength and weight savings. We use carbon fiber and glass fiber reinforced polymers.

Test Data (For Reference Only):

Carbon fiber: Tensile strength 3500 MPa, Modulus 230 GPa

Glass fiber: Tensile strength 1700 MPa, Modulus 70 GPa

Weight reduction vs steel: 80-90%

- Extremely high strength-to-weight ratio

- Excellent fatigue resistance

- Corrosion resistant

- Can be tailored for specific properties

Our Crash Test Results: Aluminum vs Magnesium

We tested both materials in a simulated automotive crash test. Aluminum absorbed 25% more energy than magnesium before failure. However, magnesium was 35% lighter. The choice depends on whether weight or crash performance is more critical for your application.

Customization Process: From Design to Installation

Requirement Evaluation

We start by understanding your exact requirements. What’s the part for? What environment will it operate in? What strength and weight targets do you need?

I personally meet with every new client to make sure we get this right. Last year, we saved a client $150k by identifying that they didn’t need aerospace-grade material—standard aluminum would have worked perfectly.

Design & FEA Simulation

Our design team uses FEA (Finite Element Analysis) to simulate how the part will perform under load. This helps us optimize the design for strength and weight.

We recently used our AI-powered simulation to reduce weight by 20% for a drone client while actually increasing strength by 15%. The results were impressive—they increased flight time by 25%.

Manufacturing

We use laser cutting, bending, and welding to create your parts. Our equipment can hold tolerances as tight as ±0.1mm on complex geometries.

For complex parts, we use 5-axis laser cutting machines to achieve the required precision. We can cut materials as thin as 0.1mm and as thick as 25mm.

Finishing & Testing

We apply various finishes depending on your requirements—powder coating, anodizing, painting, or just a clear protective coating.

We test every part to ensure it meets your specifications. We use CMM machines for dimensional checks and tensile testers for strength verification.

Installation & Support

We can provide installation support if needed. We also offer ongoing support to ensure your parts continue to perform as expected.

We stand behind our work. If you have any issues with our parts, we’ll work with you to resolve them quickly and efficiently.

This is our CNC press brake in action—we use it to bend complex shapes with precision

Key Technical Advantages

Wall Thickness Optimization

We optimize wall thickness throughout the part to remove unnecessary material while maintaining strength.

- Reduces weight by 15-30%

- Maintains structural integrity

- Improves cost efficiency

Reinforcement Design

We use ribs, flanges, and other reinforcement features to add strength without adding much weight.

- Increases stiffness by 50-100%

- Minimal weight penalty

- Improves fatigue life

Laser Welding

We use laser welding for precise, strong welds with minimal heat input. This reduces distortion and improves quality.

- Weld strength 95% of base material

- Minimal heat-affected zone

- High precision and repeatability

Vibration Damping Structures

We design structures that minimize vibration, which is especially important for precision equipment and aerospace applications.

- Reduces vibration by 40-60%

- Improves precision and performance

- Extends component life

Strength & Lightweight Balance

We use advanced design techniques to find the perfect balance between strength and weight for each application.

- Maximizes strength-to-weight ratio

- Optimizes for specific load cases

- Reduces material usage and cost

Anti-Vibration Design

We incorporate anti-vibration features into our designs to ensure parts perform well in high-vibration environments.

- Improves stability and precision

- Reduces noise and wear

- Enhances overall performance

Application Scenarios & Our Real Cases

Automotive (EV Lightweighting)

We produce lightweight structures for EV manufacturers. Last year, we developed a battery tray that reduced weight by 35% while improving crash safety.

- Material: Aluminum alloy 6061-T6

- Weight reduction: 35% vs steel

- Crash test: Passed all regulatory requirements

- Production volume: 100,000 parts/year

Drones (Payload Optimization)

We manufacture drone frames that are both lightweight and strong. Our designs help drones carry heavier payloads and fly longer.

- Material: Magnesium alloy AZ31B

- Weight reduction: 40% vs aluminum

- Payload capacity: Increased by 25%

- Flight time: Extended by 30 minutes

Aerospace (High-Temperature Components)

We produce high-temperature components for aerospace applications. Our parts can withstand temperatures up to 600°C while maintaining strength.

- Material: Titanium alloy Ti-6Al-4V

- Operating temperature: Up to 600°C

- Weight reduction: 45% vs steel

- Certifications: AS9100, NADCAP

These precision automotive components show the quality we can achieve with lightweight materials

2026 Trends & Risk Warning

AI Design Optimization

AI is revolutionizing how we design lightweight structures. We’re using AI to optimize every aspect of the design process.

- Reduces design time by 50%

- Finds optimal designs humans might miss

- Improves performance by 20-30%

Sustainable Materials

We’re seeing huge demand for sustainable materials. Our recycled aluminum and biodegradable composites are gaining popularity.

- Recycled aluminum reduces carbon footprint by 95%

- Biodegradable composites available for non-structural parts

- Meets increasing regulatory requirements

Smart Manufacturing

We’re integrating sensors and data analytics into our manufacturing processes to improve quality and efficiency.

- Real-time quality monitoring

- Predictive maintenance reduces downtime

- Process optimization improves yield

Risk Warning

We’ve seen some clients make the mistake of choosing the lightest material without considering other factors. Last year, a client insisted on using magnesium for an outdoor application without proper corrosion protection. The parts failed within 6 months.

Always consider the entire application environment—corrosion, temperature, load conditions, and cost—when selecting a material. We’re here to help you make the right choice.

FAQ (We Get These Questions Every Day)

How do you measure part quality?

We use a combination of CMM machines, vision systems, and manual inspection. For critical parts, we inspect 100% of production. For high-volume parts, we use statistical process control with sampling rates based on risk.

What’s the typical lead time for custom parts?

It depends on complexity and quantity. Simple parts can be done in 4-6 weeks. Complex parts with tooling can take 12-16 weeks. We always provide a detailed timeline before starting any project.

Do you work with aerospace and medical industries?

Absolutely. We’re AS9100 certified for aerospace and ISO 13485 certified for medical devices. We understand the strict requirements for these industries.

What about environmentally friendly materials?

We offer several sustainable options including recycled aluminum, biodegradable composites, and materials with low carbon footprints. Each has its own advantages and limitations.

How do you prevent defects like warping and distortion?

We use FEA simulation to predict and prevent distortion before manufacturing. We also use specialized fixturing and process techniques to minimize warping during production.

What strength calculations do you perform?

We perform a variety of strength calculations including static strength, fatigue analysis, buckling analysis, and vibration analysis. The specific calculations depend on the application requirements.

Start Your Lightweight Sheet Metal Journey

Share your application scenarios and requirements with us. We’ll provide a free evaluation and quote. With 15 years of experience, we’re ready to help you achieve extreme lightweighting for your products.

Important Notice

All technical data and recommendations in this article are based on our 15 years of experience and actual production results. However, every project is unique. Always conduct proper testing and validation before full production. Results may vary depending on specific materials, equipment, and process parameters.