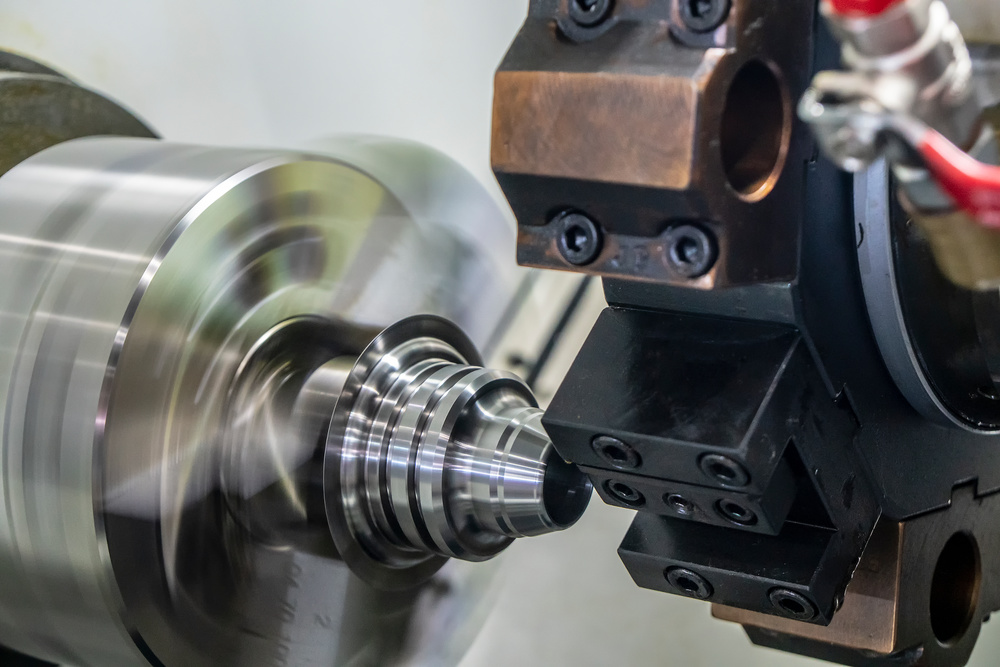

Our Machining Processes

High-precision CNC lathe turning steel components

CNC Machining Processes

- Milling: Perfect for complex shapes and flat surfaces

- Turning: Bro, this is where we shine for cylindrical parts!

- Drilling & Tapping: Precise holes with threads – no guesswork here

- Grinding: Mirror-like finishes when you need that perfect look

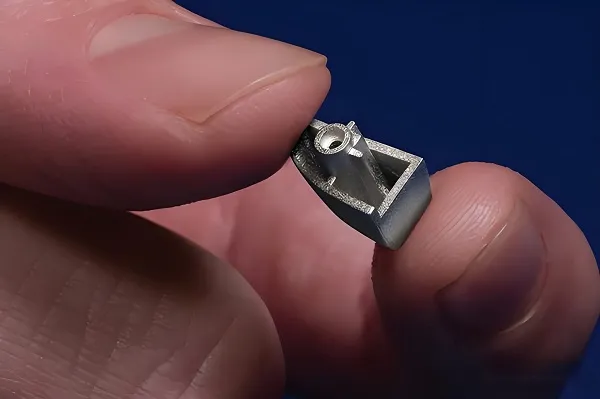

- Wire EDM: For those super intricate details that regular tools can’t handle

Why CNC Machining Rocks

Dude, I’ve tried other methods – stamping, casting, 3D printing. But when it comes to steel parts with tight tolerances? CNC machining is king. The consistency is unreal!

Steel Materials We Master

*Test data for reference only – actual results may vary

Q: What’s the hardest steel you’ve machined?

A: Dude, D2 tool steel is a beast! It’s like trying to machine a rock. But when you get that perfect finish? So satisfying. Just make sure you’ve got good carbide tools – HSS won’t stand a chance!

Where Our Parts Shine

Aerospace

Engine components, landing gear parts, structural brackets – we hit those tight tolerances that keep planes in the sky!

Automotive

Transmission parts, brake components, engine blocks – we make parts that handle the heat and stress of daily driving.

Medical

Surgical instruments, implant components, device housings – biocompatible and precise down to the micron.

Industrial

Gearboxes, pumps, valves, machine frames – parts that keep factories running 24/7.

Energy

Oil drilling components, wind turbine parts, power generation equipment – tough parts for tough environments.

Defense

Weapons components, vehicle parts, communication equipment – precision that can mean the difference between success and failure.

Why Choose Our Custom Steel Parts?

Check out those sparks – this is what precision machining looks like!

- Unmatched Precision: Tolerances down to ±0.005mm – your parts will fit like a glove

- Consistency: Every part is identical – no more “close enough” from manual machining

- Complex Geometry: We make shapes that other shops say are “impossible”

- Fast Turnaround: Bro, we’ve got the machines and the skills to get it done quick

- Quality Control: 100% inspection before shipping – we catch the mistakes so you don’t have to

- Cost Effective: Less material waste, less labor, more efficient production

Real Talk

I’ve been machining steel for 15 years. The difference between a good part and a great part? It’s in the details. And we sweat those details like nobody’s business!

Standards We Live By

ISO 9001:2015

Quality management system certification – we’ve got processes that work!

AS9100D

Aerospace quality standard – when lives depend on your parts, you need this

ISO 13485:2016

Medical device quality standard – biocompatibility and traceability

Q: Why should I care about these standards?

A: Dude, standards matter! They’re not just pieces of paper. When we say we meet AS9100D, that means your aerospace parts are made to the same standards as what goes on commercial jets. Peace of mind, right?

2026 Trends in Steel Machining

AI-Powered Machining

Bro, our new AI system adjusts feeds and speeds in real-time. It’s like having a master machinist watching every cut!

Closed-Loop Systems

We measure while we cut and automatically correct. No more guessing if parts are in spec!

Sustainable Machining

We’re using eco-friendly coolants and recycling 95% of our steel chips. Green manufacturing isn’t just a trend – it’s the future!

5-Axis Machining

Our new 5-axis machines mean we can make complex parts in one setup. Faster, more accurate, less expensive!

Frequently Asked Questions

Q: What’s the smallest tolerance you can hold?

A: Dude, we regularly hold ±0.002mm on critical features. That’s like the thickness of a human hair! But it depends on the material and part size.

Q: How long does a typical custom part take?

A: Simple parts? A few days. Complex parts with multiple operations? Maybe a couple weeks. But we’ll give you a real quote – no BS!

Q: Do you work with startups or only big companies?

A: We love startups! Some of our best clients started in garages. Whether you need 1 prototype or 10,000 production parts, we’re here for you.

Q: What file formats do you accept?

A: STEP, IGES, SolidWorks, Fusion 360, AutoCAD – we take it all. Just send us what you’ve got, and we’ll make it work.

Q: Can you help with design for manufacturability?

A: Absolutely! We’ll look at your design and suggest ways to make it cheaper to produce without sacrificing quality. It’s like getting free engineering advice!

How To Get Your Custom Steel Parts

- 1

Send Us Your Design: Email us your CAD files or even just a sketch – we’ll work with what you’ve got! - 2

Get a Quote: We’ll review your design and send you a detailed quote with lead time – usually within 24 hours! - 3

Approve & Pay: Once you approve the quote, we’ll start production. We accept all major payment methods. - 4

We Manufacture: Our team gets to work making your parts with our state-of-the-art CNC machines. - 5

Quality Inspection: Every part gets inspected to ensure it meets your specifications. No junk leaves our shop! - 6

Fast Delivery: We ship your parts anywhere in the world. Fast, secure, and tracked!

Ready to Get Started?

Send us your design today and let’s make your custom steel parts a reality! Whether you need one prototype or 10,000 production parts, we’ve got you covered.