Core Processing Technologies: Engineering for Machinery Durability

1. High-Precision CNC Machining

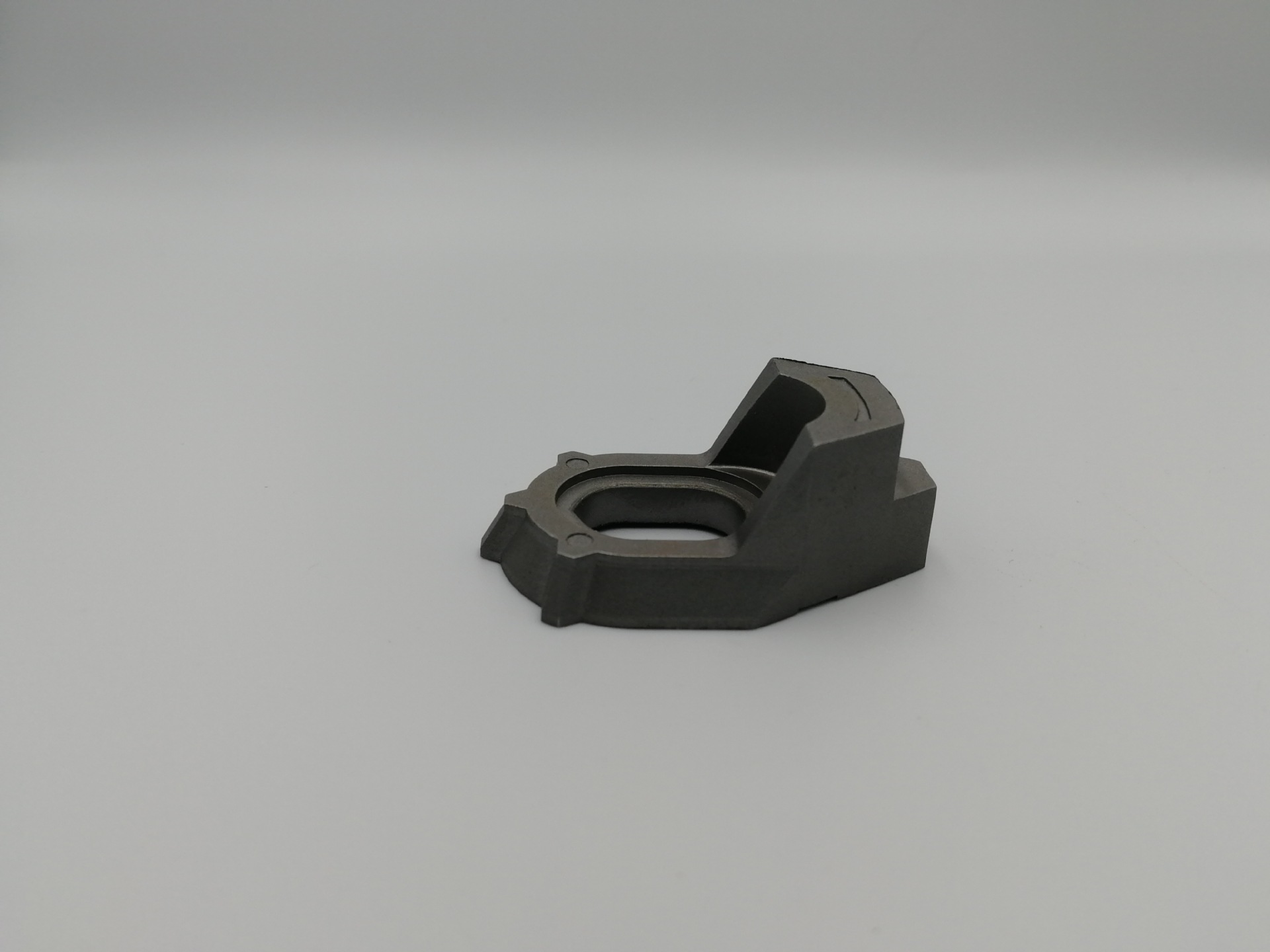

- 5-axis CNC milling: Shapes complex components (e.g., hydraulic manifolds with multi-axis ports) with ±0.005mm accuracy, ensuring fluid flow efficiency (pressure loss ≤5%). A 6-inch hydraulic manifold for industrial presses achieved 0.01mm port alignment, eliminating leaks.

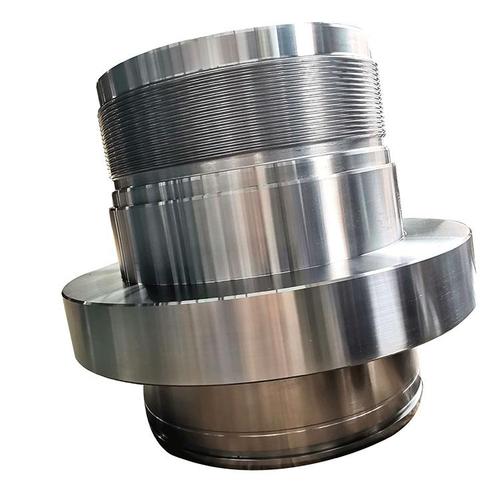

- CNC turning with live tooling: Produces shafts, bushings, and collars with tight concentricity (≤0.002mm), critical for high-speed rotating parts. A 30mm drive shaft for conveyor systems maintained balance at 3,000 RPM, reducing vibration by 60%.

- Wire EDM cutting: Creates precision gears and keyways (tolerance ±0.003mm) in hardened steel, ensuring mesh accuracy (backlash ≤0.05mm) for gearboxes.

2. Heat Treatment & Material Strengthening

- Carburizing & quenching: Hardens gear teeth and bearing surfaces to 58-62 HRC, with a ductile core (30-35 HRC) for impact resistance. A 40-tooth industrial gear treated this way endured 10 million cycles without wear.

- Nitriding: Enhances surface hardness of hydraulic components (e.g., valve spools) to 1,000HV, reducing friction and extending service life by 3x in oil-rich environments.

- Stress relief annealing: Eliminates internal stresses in large parts (e.g., 1m-long conveyor frames), preventing warpage under continuous load (≤0.02mm/m deformation).

3. Surface Coating & Corrosion Resistance

- Hard chrome plating: Applied to hydraulic rods and piston shafts, providing 0.05-0.1mm thick wear layers (65 HRC) and corrosion resistance (500 hours salt spray).

- Powder coating: For structural parts (e.g., machine frames), offers 80-120μm thick layers with UV resistance, ideal for outdoor agricultural machinery.

- PTFE coating: Reduces friction on sliding components (e.g., linear guide rails) by 40%, ensuring smooth operation in food processing equipment (compliant with FDA 21 CFR 177.1550).

4. Quality Testing for Industrial Reliability

- Dimensional inspection: CMMs verify critical features—bearing seat tolerance (H7), gear pitch (±0.01mm), and shaft straightness (≤0.05mm/m).

- Mechanical testing: Tensile strength (≥600MPa for structural parts), impact resistance (-40℃, ≥27J), and fatigue testing (10 million cycles at 80% load) ensure durability.

- Pressure testing: Hydraulic manifolds and valves undergo 3x working pressure tests (e.g., 300bar for industrial hydraulics) with zero leakage.

Material Expertise: Matching Metals to Machinery Needs

|

Material

|

Key Properties

|

Application

|

Advantages

|

|

Alloy Steel (4140, 4340)

|

High tensile strength (800-1,200MPa), wear resistance

|

Gearboxes, drive shafts, hydraulic cylinders

|

Withstands high torque; ideal for heavy machinery.

|

|

Stainless Steel (304, 316)

|

Corrosion resistance, hygiene compliance

|

Food processing equipment, marine machinery

|

500+ hours salt spray resistance; easy to clean.

|

|

Cast Iron (Gray, Ductile)

|

Vibration damping, low cost

|

Bearing housings, machine bases

|

Absorbs 30% more vibration than steel; economical for large parts.

|

|

Aluminum Alloy (6061-T6)

|

Lightweight, high thermal conductivity

|

Conveyor components, precision manifolds

|

30% lighter than steel; reduces energy consumption in moving parts.

|

Machinery Parts Machining Technologies

- Multi-axis CNC machining: 5-axis mills produce complex hydraulic manifolds with intersecting ports (±0.01mm position tolerance), eliminating assembly leaks in industrial presses.

- Precision grinding: Cylindrical grinding achieves Ra 0.02μm surface finish on bearing seats, reducing friction and extending bearing life by 50%.

- Automated production cells: Robotic loading/unloading and in-line CMM inspection ensure 99.9% consistency for high-volume parts (e.g., 10,000 conveyor rollers/month).

Custom Machinery Parts Manufacturing Process

- Design & DFM: Engineers analyze client CAD files (STEP/IGS) to optimize for load distribution—e.g., adding fillets to gear teeth to prevent fatigue failure.

- Material selection: Choose alloy steel for high-torque parts (e.g., 4140 for drive shafts) or 316 stainless for corrosive environments (e.g., chemical processing equipment).

- CNC machining: Milling/turning creates base features; wire EDM adds precision details (keyways, gear teeth); grinding refines bearing surfaces.

- Heat treatment: Carburizing/quenching enhances surface hardness, followed by stress relief to prevent warping under load.

- Surface coating: Chrome plating or powder coating applied per environment (e.g., food-grade coatings for 304 parts).

- Quality validation: CMM inspection, pressure testing, and fatigue trials ensure compliance with ISO 9001 and client specs.

Custom Machinery Parts Application Fields

- Industrial machinery: Gearboxes, hydraulic manifolds, and bearing housings for injection molding machines, presses, and robotics (alloy steel, 4140).

- Agricultural equipment: wear-resistant steel plow components, stainless steel irrigation system parts (resistant to fertilizer corrosion).

- Food processing: 304 stainless steel conveyor belts, hydraulic cylinders with FDA-compliant coatings (easy to sanitize).

- Construction machinery: Ductile iron bearing housings, high-strength steel bucket teeth (withstand 500+ hours of rock impact).

- Medical equipment: Aluminum alloy precision manifolds for diagnostic machines (lightweight, corrosion-resistant).

Customization Capabilities: From Prototype to Production

- Design optimization: FEA analysis ensures parts (e.g., crane hooks) withstand 2x working load without deformation, meeting OSHA standards.

- Low-volume flexibility: 1-1,000 units via CNC machining for prototype testing (e.g., agricultural gearbox prototypes in 5 days).

- High-volume production: 10,000+ units/month with multi-cavity tooling and automated lines (e.g., 50,000 conveyor rollers for logistics systems).

Common Processing Questions

- Q: How to ensure gearboxes handle 10,000Nm torque without failure?

- Q: What’s the lead time for 500 hydraulic manifolds (4140 steel)?

- Q: Can parts withstand -40℃ temperatures (e.g., cold storage machinery)?

- Q: How to reduce vibration in high-speed machinery (3,000 RPM)?

Why Choose Goldcattle?

- Industrial expertise: 26 years in machinery parts, with 200+ designs meeting ISO 9001/OSHA standards for heavy equipment.

- Quality assurance: 100% CMM inspection, pressure testing, and fatigue trials; full material traceability (heat codes, certificates).

- Cost efficiency: Design-to-cost engineering (e.g., integrating 3 parts into 1) reduces assembly time by 40% for clients.

- Global compliance: Parts meet EU CE, US OSHA, and food-grade FDA standards, suitable for multinational machinery brands.