Introduction: Why Complex Stainless Steel Parts Are Challenging to Machine

As a procurement manager, you know that finding a reliable supplier for complex-shaped stainless steel parts can be frustrating. Stainless steel itself presents unique challenges – its high strength and toughness demand specialized tools and techniques. Add complex geometries into the mix, and suddenly many suppliers fall short.

The reality is that most manufacturers struggle with:

- Inconsistent precision and tolerances

- Unreliable delivery schedules

- Higher than expected costs due to machining difficulties

- Limited capability for truly complex designs

At XiaMenGoldCattle, we’ve spent over a decade perfecting the art of machining complex stainless steel components. We understand these challenges firsthand and have developed specialized processes to overcome them.

Machinable Stainless Steel Grades: Matching Your Industry Needs

We work with a comprehensive range of stainless steel grades, each selected for specific performance characteristics:

Standard Austenitic Grades:

- 304/304L: Excellent corrosion resistance, good machinability, and cost-effective. Ideal for food processing equipment, chemical containers, and architectural components.

- 316/316L: Superior corrosion resistance with molybdenum addition. Perfect for marine environments, medical devices, and pharmaceutical equipment.

- 303: Enhanced machinability with sulfur additions, making it suitable for intricate parts with complex geometries.

Specialty Grades:

- 17-4PH: Precipitation-hardening stainless steel offering high strength and good corrosion resistance. Used in aerospace components and high-performance applications.

- 420: Martensitic stainless steel that can be heat-treated for high hardness. Excellent for cutting tools and medical instruments requiring sharp edges.

Each grade responds differently to machining processes. Our engineers carefully select the optimal material based on your application requirements, balancing performance, machinability, and cost.

Complex Structures We Specialize In

Our advanced equipment and expertise allow us to machine even the most challenging geometries:

Asymmetrical & Irregular Shapes

Parts with non-uniform profiles that require multi-axis machining to achieve precision.

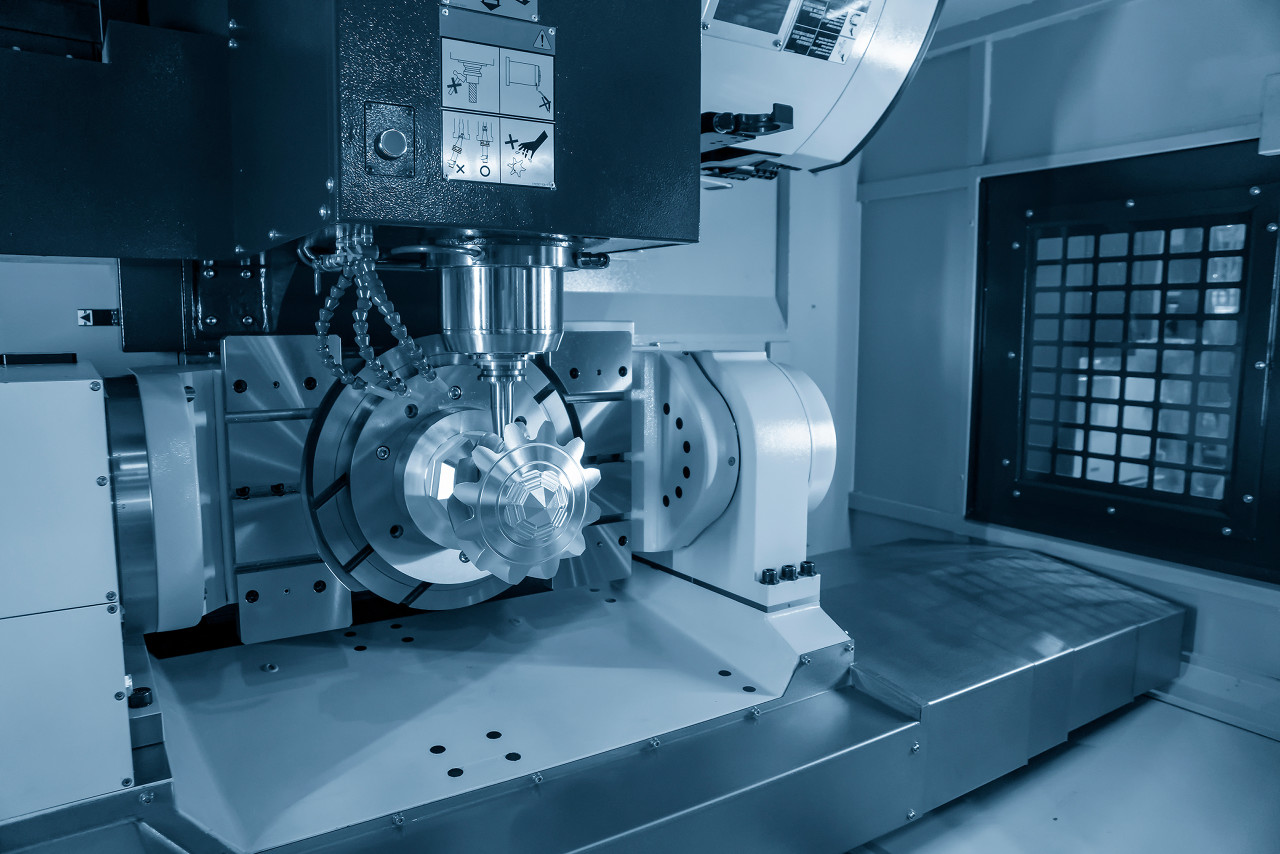

Multi-Surface & Angled Features

Utilizing 5-axis machining centers to create parts with complex angles and intersecting surfaces.

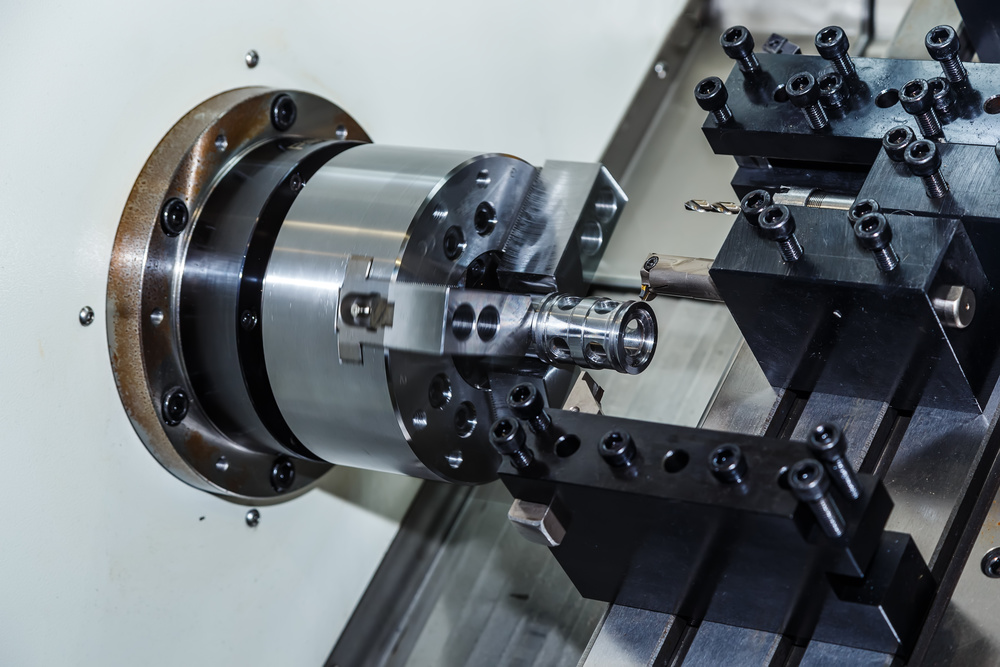

Deep Cavities & Blind Holes

Specialized tooling and techniques to machine deep features without compromising accuracy.

Thin-Wall Structures

Capable of machining walls as thin as 0.5mm while maintaining dimensional stability.

Micro Components

From intricate medical devices to robust industrial components, our capabilities extend to the most demanding designs.

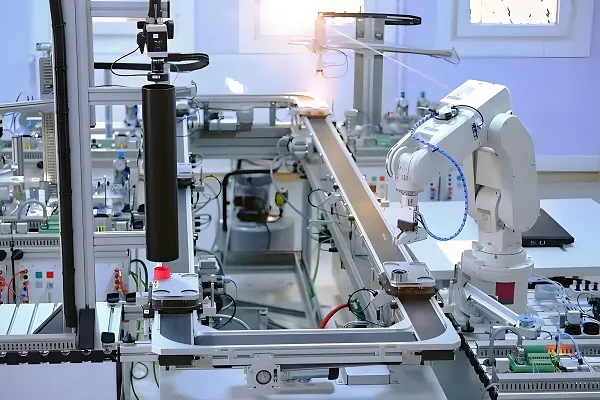

Advanced Machining Capabilities & Equipment

Our manufacturing facility is equipped with state-of-the-art equipment to handle complex stainless steel machining:

Precision CNC Turn-Mill Centers

Combining turning and milling operations in a single setup for increased efficiency and accuracy.

5-Axis Machining Centers

Simultaneous 5-axis movement allows for complex geometries and reduced setup times.

EDM (Electrical Discharge Machining)

Ideal for extremely small or intricate internal features that conventional machining can’t reach.

Laser Cutting & Welding

Precision cutting and joining of stainless steel components with minimal heat affected zones.

Size Capabilities: From 0.5mm micro-components up to 600mm large parts.

Precision & Tolerance Capabilities

Standard Tolerances: ±0.01mm for most components

High-Precision Tolerances: ±0.005mm for critical applications

Ultra-Precision Options: ±0.002mm for specialized requirements

Surface Finish Options:

- Ra 3.2: Standard machining finish

- Ra 1.6: Fine machining finish

- Ra 0.8: Precision grinding finish

We maintain dimensional consistency through advanced fixture design, optimized tool paths, and real-time process monitoring.

Post-Processing & Surface Treatment Options

Proper surface treatment is essential for stainless steel components to ensure corrosion resistance and functionality:

Mechanical Finishing:

- Deburring and edge rounding

- Sandblasting for matte finishes

Chemical Treatments:

- Passivation to enhance corrosion resistance

- Electropolishing for improved surface finish and cleanliness

Specialized Finishes:

- Mirror polishing for aesthetic applications

- Medical-grade surface treatments for implantable devices

Streamlined Customization Process

We’ve developed a straightforward process to make custom stainless steel machining easy for our clients:

Step 1: Design Submission

Submit your 2D drawings, 3D models, or CAD files in STEP, PDF, or other common formats.

Step 2: Engineering Analysis

Our experienced engineers perform a comprehensive DFM (Design for Manufacturability) analysis to optimize your design.

Step 3: Quotation

We provide a detailed quote based on part complexity, material selection, precision requirements, and production volume.

Step 4: Prototyping

Rapid prototyping allows for design verification before full production.

Step 5: Production & Quality Control

Precision manufacturing with rigorous quality inspection at every stage.

Step 6: Global Delivery

Secure packaging and reliable shipping to destinations worldwide.

Comprehensive Quality Control System

Quality is the foundation of everything we do at XiaMenGoldCattle:

Advanced Inspection Equipment:

- Coordinate Measuring Machines (CMM) for 3D dimensional analysis

- 2.5D projectors for precision measurement

- Surface roughness testers

- Hardness testing equipment

Quality Documentation:

- First Article Inspection (FAI) reports

- Complete dimensional inspection reports

- Material certificates with full traceability

- ISO 9001:2015 certification

Process Controls:

- Statistical Process Control (SPC)

- Batch consistency monitoring

- Regular equipment calibration

- Operator training and certification

Industry Applications: Solutions We’ve Delivered

Our custom stainless steel machining services serve a wide range of industries:

Automotive & Transportation:

- Complex metal brackets and mounting systems

- Sensor housings and precision components

- Exhaust system parts requiring high-temperature resistance

Medical & Pharmaceutical:

- 316L stainless steel surgical instruments

- Implantable medical devices

- Pharmaceutical processing equipment components

Industrial Machinery:

- High-strength fasteners and connectors

- Gear components and transmission parts

- Hydraulic and pneumatic system components

Marine & Offshore:

- Corrosion-resistant structural components

- Valve bodies and fluid handling parts

- Marine hardware and fittings

Cost Factors: Understanding Your Investment

Part Complexity: Intricate designs with multiple features require more machining time and specialized tooling.

Material Selection: Premium grades like 316L or 17-4PH cost more than standard 304 stainless steel.

Precision Requirements: Tighter tolerances and finer surface finishes increase production time and costs.

Surface Treatments: Specialized coatings or treatments add to the overall cost but provide valuable performance benefits.

Production Volume: Economies of scale apply – larger production runs typically reduce unit costs.

Lead Time: Rush orders may incur additional charges for expedited production.

Our quoting team works closely with you to balance performance requirements with budget considerations, offering value engineering suggestions when appropriate.

26+ Years of Specialized Experience

Decades of focused expertise in stainless steel machining ensures consistent quality and reliability.

Small Batch to Mass Production

We excel at both rapid prototyping and high-volume production, with flexible capacity to meet your needs.

Advanced 5-Axis Machining Capabilities

Our multi-axis equipment handles the most complex geometries with precision.

Engineering Support & DFM Analysis

Our team provides valuable design insights to optimize manufacturability and reduce costs.

Global Project Experience

We’ve successfully delivered projects to clients worldwide, understanding international standards and requirements.

Strict Confidentiality

We offer comprehensive NDA agreements to protect your intellectual property.

Get Your Custom Quote Today

Ready to start your complex stainless steel machining project? We make it easy:

Submit Your Design: We accept STEP, PDF, 3D models, and CAD files.

Fast Response: Our team provides quotes within 24 hours for most projects.

At XiaMenGoldCattle, we’re committed to delivering precision stainless steel components that meet your exact specifications. Contact us today to discuss your project requirements and experience the difference that specialized expertise makes.

.jpg)

.jpg)

.jpg)