In the relentless pursuit of powerful power, lightweight design, and high durability in the motorcycle industry, cylinder die castings, with their excellent resistance to high temperatures, high wear resistance, and complex structure forming capabilities, have become the core key components of motorcycle engines. Their performance directly affects the power output, fuel economy, and service life of motorcycles. Whether it’s high-performance sports bikes striving for ultimate speed or long-distance touring models emphasizing durability, custom motorcycle cylinder die castings play a crucial role.

Table of Contents

- Motorcycle Cylinder Die Castings: The Core Components of Motorcycle Power

- Customized Material Selection: Material Solutions for Harsh Working Conditions

- Precision Manufacturing Process: The Transformation from Liquid Metal to High-quality Cylinders

- Core Technological Breakthroughs: Conquering High Temperature, High Pressure, and High Wear Challenges

- Full-process Quality Control: Quality Assurance under High Standards

- Agile Service System: Efficient Response to Diverse Needs

- Motorcycle Cylinder Die Casting FAQs: Professional Answers to Core Customization Questions

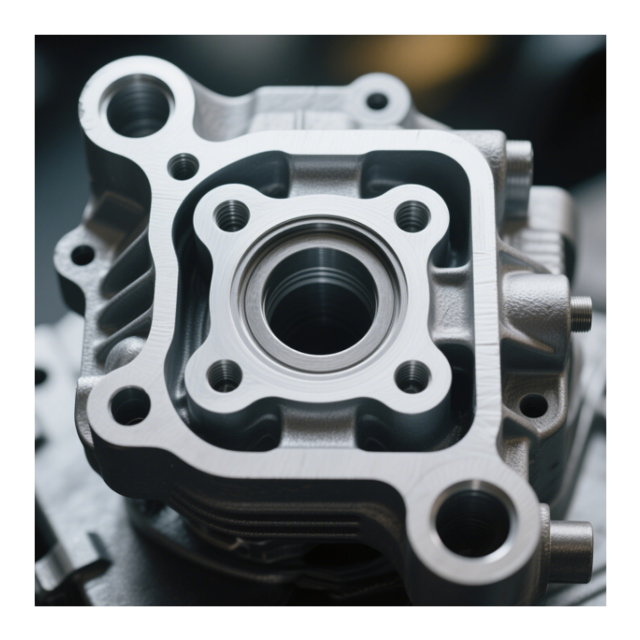

1. Motorcycle Cylinder Die Castings: The Core Components of Motorcycle Power

Motorcycle cylinder die castings undertake core functions such as gas compression, energy conversion, and heat transfer, which are crucial for the stable operation of engines:

- Adaptability to Extreme Conditions: Capable of continuous operation in a high-temperature environment of 200°C – 300°C and withstanding an explosion pressure of 12 – 18MPa, cylinder die castings require a tensile strength of ≥300MPa to ensure stable operation during high-speed driving and frequent gear shifting.

- Integration of Complex Structures: Through integrated die casting technology, precise forming of complex structures such as the inner wall of the cylinder, cooling fins, and lubricating oil channels (cylindricity tolerance of the inner wall ±0.005mm) is achieved, reducing the processing procedures by 30% and improving overall sealing and reliability.

- Lightweight Requirements: Compared with traditional cast iron cylinders, aluminum alloy die castings can achieve a weight reduction of 35% – 55%, effectively reducing the engine’s self-weight, improving the motorcycle’s acceleration performance and handling flexibility, and reducing fuel consumption by 5% – 8%.

2. Customized Material Selection: Material Solutions for Harsh Working Conditions

1. Performance and Typical Applications of Main Alloys

| Alloy Type | Typical Grade | Core Performance Indicators | Application Scenarios |

|---|---|---|---|

| Aluminum Alloy | A380 | Tensile strength ≥320MPa, high-temperature hardness retention ≥70% | Cylinders of high-performance sports bikes |

| Aluminum Alloy | ADC12 | Thermal conductivity ≥180W/(m·K), good casting fluidity | Cylinders of general-purpose motorcycles |

| Silicon-containing Aluminum Alloy | Al – Si12Cu | Excellent wear resistance, low coefficient of thermal expansion | Cylinders of high-speed engines |

2. Customized Material Design

- Reinforcement of High-performance Cylinders: Adding 0.5%Mg + 0.3%Ni to the A380 alloy increases the tensile strength by 18% at 300°C and extends the thermal fatigue life by 25%, meeting the operation requirements of high-speed and high-load for high-performance motorcycles.

- Optimization of Wear Resistance: Precisely controlling the silicon content within 11.5% – 12.5% in the silicon-containing aluminum alloy and carrying out modification treatment can enhance the wear resistance by 30%, effectively reducing the wear between the piston and the cylinder wall and extending the service life of the cylinder.

3. Precision Manufacturing Process: The Transformation from Liquid Metal to High-quality Cylinders

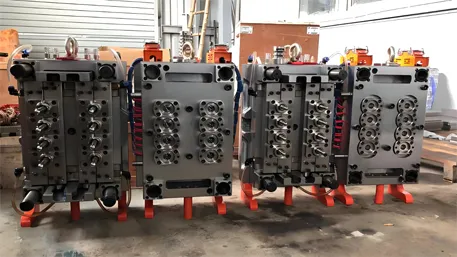

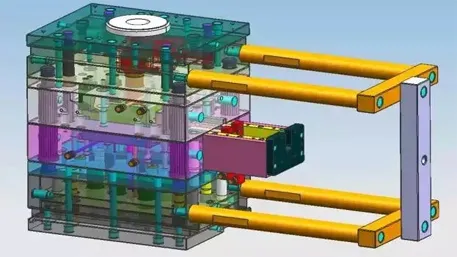

1. Mold Design: Micron-level Precision Control

- Optimization of Hot Runner and Cooling System: Using Moldflow for mold flow analysis, optimizing the gate position and the layout of the cooling water channel, reducing the filling time by 20%, and improving the cooling uniformity of the cylinder wall, with the deformation controlled within ±0.02mm.

- Mold Processing Technology:

- Using slow wire electrical discharge machining to process the high-precision mold cavity, with an accuracy of ±0.003mm, ensuring the cylindricity of the inner wall of the cylinder ≤0.005mm;

- The mold surface is treated with TD coating (film thickness 3 – 5μm), increasing the hardness to 3200HV, effectively reducing the sticking phenomenon and extending the mold life by 40%.

2. Die Casting: Exclusive Process for Motorcycle Cylinders

- Vacuum High-pressure Die Casting: Controlling the vacuum degree at ≤60mbar, with a three-stage pressure boost technology (initial pressure 80MPa → intermediate pressure 120MPa → final pressure 160MPa), achieving an internal density of cylinders ≥99.6%, and an X-ray flaw detection defect rate <0.1%.

- Intelligent Temperature Control System: Real-time monitoring and precise control of the mold temperature (aluminum alloy mold 180±3°C), ensuring that key dimensions of the cylinder fluctuate ≤±0.015mm, meeting high-precision assembly requirements.

3. Post-processing: Double Improvement of Performance and Precision

- Precision Machining:

- Using a CNC honing machine to process the inner wall of the cylinder, with a surface roughness Ra≤0.2μm and a cylindricity ≤0.003mm, effectively reducing the piston running resistance and improving the engine efficiency;

- Precision milling of the cooling fins, with the fin thickness tolerance controlled within ±0.1mm, ensuring uniform and stable heat dissipation.

- Surface Treatment Process:

- The inner wall of the cylinder is treated with hard chromium plating (film thickness 0.03 – 0.05mm), with a hardness ≥800HV, increasing the wear resistance by 5 times;

- The outer wall of the cylinder is anodized to form a 20μm thick oxide film, enhancing corrosion resistance and providing personalized appearance options.

4. Core Technological Breakthroughs: Conquering High Temperature, High Pressure, and High Wear Challenges

1. High-temperature Strength and Thermal Fatigue Technology

- Grain Refinement Treatment: Adding 0.2%Ti + 0.15%B to the aluminum alloy, refining the grain size to below 40μm, increasing the high-temperature fatigue strength by 30%, and being able to withstand 120,000 thermal cycles without cracks.

- Optimized Structure Design: Using finite element analysis technology, carrying out lightweight design for the cylinder, adding reinforcing ribs (thickness 1.5mm) in stress concentration areas, increasing the knock resistance by 35%.

2. Precision Wear Resistance and Lubrication System Forming

- Application of Micro-texture Technology: Processing micron-level textures (depth 5 – 10μm) on the inner wall of the cylinder to form oil storage spaces, reducing the friction coefficient between the piston and the cylinder wall by 15% and reducing wear.

- Reinforcement of Lubricating Oil Channel Sealing: Combining laser welding and helium leak detection technology to ensure the sealing of the lubricating oil channel, with a leakage rate ≤0.5cc/min, 30% better than the industry standard.

3. Upgrade of Non-destructive Testing Technology

- CT Three-dimensional Detection: Using high-precision CT scanning technology to perform full-size three-dimensional reconstruction of the cylinder, with a detection accuracy of 0.05mm, capable of detecting tiny internal defects, and a miss rate <0.02%.

- Ultrasonic Phased Array Detection: Performing ultrasonic phased array detection on key parts of the cylinder, increasing the detection sensitivity by 40%, ensuring 100% qualified cylinder quality.

5. Full-process Quality Control: Quality Assurance under High Standards

1. Raw Material Control

- Spectral Analysis: Conducting full-element spectral detection on each batch of alloys (accuracy 0.005%), strictly controlling the Si content in A380 alloy at 11.8% – 13.0%, and Fe content ≤0.9%.

- Mechanical Property Testing: Conducting multiple mechanical property tests such as tensile, impact, and hardness on raw materials, with a batch qualification rate ≥99.8%.

2. Process Monitoring

- Intelligent Manufacturing System: Real-time collection of data such as pressure, temperature, and speed during the die casting process through IoT sensors, achieving precise control of production parameters, with an abnormal response time ≤6 seconds.

- First Article Three-inspection System: Conducting full-size inspection (measurement points ≥60), metallographic analysis, and non-destructive testing on the first article, ensuring 100% qualification before mass production.

3. Finished Product Inspection

| Inspection Item | Inspection Method | Standard Requirements | Compliance Rate |

|---|---|---|---|

| Dimensional Accuracy | Coordinate Measuring Machine | Key dimensions ±0.01mm | 99.8% |

| Internal Defects | CT Scanning + Ultrasonic Testing | 0 tolerance for defects ≥0.1mm | 100% |

| Airtightness Test | Helium Mass Spectrometer | Leakage rate ≤0.5cc/min | 99.7% |

| Wear Resistance | Friction and Wear Tester | Wear amount ≤0.01mm/100 hours | 99.5% |

6. Agile Service System: Efficient Response to Diverse Needs

1. Collaborative R&D

- Early Intervention in Design: Providing DFM (Design for Manufacturability Analysis) services during the customer’s product development stage, optimizing the cylinder structure design, reducing the mold development cost by 25%, and shortening the development cycle by 18%.

- Joint Technical Research: Collaborating with customers on the research and development of new materials and processes, developing high thermal conductivity and low-noise aluminum alloy materials for the cylinders of electric motorcycles, increasing the thermal conductivity efficiency by 28%.

2. Rapid Delivery

- Rapid Prototyping Service: Combining 3D printing and simple molds, the first sample can be delivered within 5 days, shortening the prototyping cycle by 65% compared with traditional methods.

- Flexible Production Capacity: Equipped with 300 – 600T die casting machines, with a monthly production capacity of 150,000 pieces, shortening the delivery cycle of conventional cylinders by 32% compared with the industry average.

3. After-sales Guarantee

- Full Lifecycle Service: Providing a full-process service from product design, manufacturing to after-sales maintenance, establishing a product quality traceability system to achieve rapid positioning and resolution of problems.

- Technical Support Team: The professional technical team responds to customer needs 24 hours a day, providing on-site technical guidance, assisting customers in solving problems such as assembly and performance optimization, with a customer satisfaction rate of 98%.

7. Motorcycle Cylinder Die Casting FAQs: Professional Answers to Core Customization Questions

Q1: What are the commonly used aluminum alloy grades for motorcycle cylinder die castings?

A: Commonly used grades include A380 (high strength, high temperature resistance), ADC12 (high thermal conductivity, good fluidity), and Al – Si12Cu (high wear resistance). The most suitable material can be recommended according to the type and performance requirements of the motorcycle.

Q2: How to ensure the wear resistance of motorcycle cylinders?

A: Using silicon-containing aluminum alloy and carrying out modification treatment, and at the same time, performing hard chromium plating treatment (hardness ≥800HV) on the inner wall of the cylinder. In addition, micro-texture technology is used to reduce friction, ensuring high wear resistance of the cylinder.

Q3: What is the mold life of custom motorcycle cylinder die castings?

A: The standard mold life is 500,000 – 700,000 cycles. Using high-performance mold steel combined with TD coating treatment, the mold life can be increased to more than 1 million cycles, and mold maintenance services are provided.

Q4: How long does it take from drawing confirmation to mass production?

A: The standard cycle is: requirement confirmation 3 days → mold design 10 days → mold processing 28 days → trial casting 6 days → production preparation 4 days, totaling about 51 days; for urgent projects, it can be compressed to within 38 days through concurrent engineering.

Get an Exclusive Customized Solution Now

The powerful power and excellent performance of motorcycles start with the precision quality of cylinder die castings. Whether you are a motorcycle OEM or an enterprise focusing on high-performance modifications, customized motorcycle cylinder die castings can provide you with a comprehensive solution from materials to processes. Leave your requirements now – please specify the type of motorcycle, performance requirements, and annual demand, and we will customize an exclusive technical solution and efficient delivery plan for you within 24 hours.

(Message area: Please specify the type of motorcycle, performance requirements, and annual demand in detail, and we will reply within 24 hours)