Overview of CN Medical Parts

Custom medical parts service is a vital component in the development of modern medical technology. As medical technology continues to advance, the complexity and precision requirements of medical equipment have increased, making it difficult for traditional standardized parts to meet the needs of specific medical devices. Therefore, custom medical parts service emerged to provide high-precision, high-performance components for medical equipment manufacturers, ensuring the overall performance and safety of the equipment.

1. The Role of CNC in the Medical Field

CNC (Computer Numerical Control) technology plays a crucial role in the medical field, mainly reflected in the following aspects:

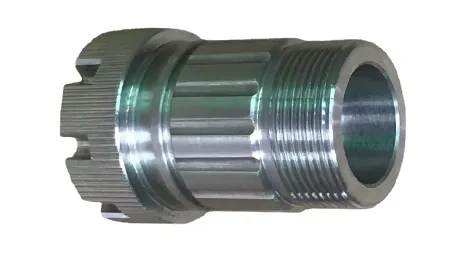

- High-Precision Manufacturing: CNC processing technology can achieve micron-level or even nanometer-level precision, which is crucial for manufacturing high-precision medical devices such as artificial joints and dental implants.

- Efficient Production: CNC processing technology enables automated production, significantly improving production efficiency and shortening product delivery cycles, meeting the high timeliness requirements of the medical industry.

- Complex Shape Processing: CNC processing technology can easily handle the processing requirements of complex shapes and structures, such as joint replacements and heart valves, improving the reliability and safety of medical devices.

- Consistency Assurance: CNC processing technology ensures product consistency and stability, reducing errors caused by human factors and improving product quality.

2. Medical Parts CNC Technology

Medical parts CNC technology mainly includes the following aspects:

- Five-Axis CNC Machining: Five-axis CNC machining technology enables precise processing of complex curved surfaces, reducing manual intervention and improving processing precision. This technology is particularly important in the manufacturing of high-precision medical devices such as artificial joints and heart valves.

- Laser Cutting and Welding: Laser cutting and welding technology is used for precision processing and joining of medical parts, such as welding endoscope modules, ensuring strong connections between parts without compromising their performance.

- Electrochemical Machining: Electrochemical machining technology is used for manufacturing micro-parts or precision surface treatment, such as the manufacture of micro-electrodes, ensuring dimensional accuracy and surface quality of parts.

3. Advantages of CNC Processing Medical Parts

CNC processing of medical parts offers numerous advantages:

- High Precision: CNC processing technology can achieve micron-level precision, meeting the strict precision requirements of medical devices.

- Efficient Production: Automated production increases production efficiency and shortens product delivery cycles.

- Complex Shape Processing Capability: Capable of processing medical device components with complex geometric shapes.

- Broad Material Adaptability: Can flexibly adjust cutting parameters and tool types based on the physical properties and processing requirements of different materials.

- Shortened Research and Development Cycle: Rapid prototyping and iterative optimization accelerate product launch speeds.

4. Materials for CNC Processed Medical Parts

| Material | Description |

|---|---|

| Stainless Steel | High corrosion resistance and biocompatibility |

| Titanium Alloy | Lightweight, high strength, and excellent biocompatibility |

| Ceramic | High hardness and wear resistance |

| Polymers | Good biocompatibility, various forms and functions |

5. Standards and Requirements for Medical Parts

The standards and requirements for medical parts are very strict, mainly including the following aspects:

- High Precision: The precision of medical equipment requires that the processing precision of parts reach micron-level or even nanometer-level.

- Biocompatibility: Parts must be non-toxic, non-irritating, and compatible with human tissue to avoid immune reactions or rejection.

- Sterilization: All parts must undergo strict cleaning, sterilization, and aseptic packaging after processing to ensure a sterile state during use.

- Reliability Testing: Rigorous reliability testing, including durability testing, environmental adaptability testing, and electrical performance testing, is required after design completion.

6. Introduction to Medical Parts Processing Equipment

Medical parts processing equipment mainly includes the following categories:

- High-Precision CNC Lathes: Used for rough, semi-finish, and finish processing of parts, ensuring dimensional accuracy and surface quality.

- Laser Cutters and Welders: Used for precision cutting and joining of parts, such as welding endoscope modules.

- Electrochemical Machining Equipment: Used for manufacturing micro-parts or precision surface treatment, such as the manufacture of micro-electrodes.

- Coordinate Measuring Machines (CMMs): Used for measuring the dimensions, shapes, positional accuracy, and surface quality of parts to ensure they meet design requirements.

8. Xiamen Goldcattle Medical Parts Evaluation

Xiamen Goldcattle enjoys a good reputation in custom medical parts services. The company possesses advanced CNC processing technology and extensive manufacturing experience, providing customers with high-precision, high-quality medical parts. Its products have the following characteristics:

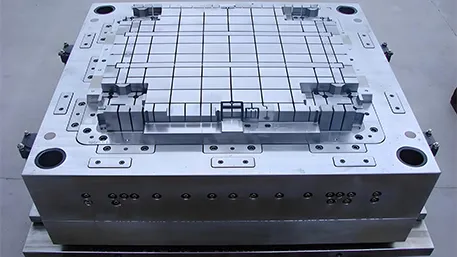

- High-Quality Materials: Uses high-quality materials such as S136, NAK80, and 718H to ensure the durability and lifespan of mold tools.

- Flexible Design: Offers single-cavity and multi-cavity mold options to meet user-specified sizes and design requirements.

- Strict Quality Control: Certified by ISO 9001:2008, ensuring products comply with international quality standards and regulations.

- Efficient Delivery: Has strong production capabilities, enabling quick response to customer needs and ensuring timely delivery of products.

Custom Medical Parts Service FAQs

Q1: What is the process for custom medical parts services?

A1: The process for custom medical parts services includes demand communication, design confirmation, material selection, processing and manufacturing, quality inspection, sterilization, and delivery.

Q2: How is the biocompatibility of custom medical parts ensured?

A2: By selecting materials that meet biocompatibility requirements, such as stainless steel and titanium alloy, and conducting rigorous biocompatibility testing after processing to ensure that the parts do not adversely affect the human body during use.

Q3: How long is the delivery time for custom medical parts services?

A3: Delivery time depends on the complexity and quantity of the parts. Generally, we can complete delivery within 1-30 days after receiving the order.

Q4: Does custom medical parts service provide after-sales support?

A4: Yes, we provide comprehensive after-sales support, including usage guidance, troubleshooting, and maintenance for the parts.

Through custom medical parts services, medical equipment manufacturers can obtain high-precision, high-performance components, thereby improving the overall performance and safety of their equipment. As medical technology continues to advance, custom medical parts services will continue to play a crucial role in driving the medical industry to higher levels of development.