Ready to level up your brand game? Custom plastic bottles are the secret sauce for businesses looking to stand out in a crowded market! They’re not just containers—they’re a triple threat of functionality, brand vibes, and real-world usability.

Pick your perfect size, shape, material, and design to match your product’s unique needs. These bottles don’t just look good on the shelf—they’re total conversation starters that tell your brand’s story and win over customers. Whether you’re doing a small batch run or cranking out products by the truckload, these custom bottles nail that sweet spot between performance, budget, and eco-friendliness.

1. Materials: Choosing the Right Plastic for Your Custom Bottle

The material of your custom plastic bottle directly impacts its performance, safety, and suitability for your product. Each plastic type has unique traits that make it ideal for specific uses:

- PET (Polyethylene Terephthalate): A favorite for food and beverage brands, PET offers crystal-clear clarity to showcase juices, bottled water, or sauces. It’s lightweight, shatter-resistant, and 100% recyclable—perfect for eco-conscious brands wanting to reduce their footprint. Its low permeability also keeps liquids fresh, making it a top pick for shelf-stable products.

- HDPE (High-Density Polyethylene): Known for durability and chemical resistance, HDPE shines in personal care and household products. Think shampoo bottles, laundry detergent containers, or cleaning sprays—HDPE stands up to harsh ingredients without warping or leaking. It’s also opaque, which protects light-sensitive products, and easy to recycle.

- PP (Polypropylene): Heat resistance is PP’s superpower, making it ideal for hot-fill products like syrups, soups, or baby food. It’s non-toxic, moisture-resistant, and often used in medical packaging (e.g., pill bottles) due to its compliance with strict safety standards. PP is also flexible, so it works for squeeze bottles or containers with flip-top lids.

- PVC (Polyvinyl Chloride): Less common for food contact, PVC excels in industrial or cosmetic applications. It’s flexible (great for tubes of hand cream) and cost-effective, making it a choice for budget-friendly custom bottles like travel-sized toiletries or industrial chemical containers.

Selecting the right material ensures your custom bottle doesn’t just look good—it protects your product and meets your brand’s values, whether that’s sustainability, safety, or durability.

2. Techniques: Crafting Custom Bottles with Precision

Manufacturing custom plastic bottles relies on specialized techniques, each designed to bring your unique vision to life. The right method depends on your bottle’s size, shape, and intended use:

- Injection Molding: This technique starts with melting plastic resin and injecting it into a mold—ideal for creating bottle preforms (the “blank” plastic tubes used in blow molding) or small, intricate bottles (e.g., 10ml sample vials). It’s perfect for brands needing consistent, detailed designs (like embossed logos) and works with all major plastic types. For precision components, such as tamper-evident caps or custom spouts, injection molding uses computer-controlled systems to ensure every detail is exact.

- Blow Molding: The most common method for full-size custom bottles, blow molding has two key variants:

-

- Extrusion Blow Molding (EBM): Great for irregular shapes (e.g., curved bottles) or thick-walled containers (industrial chemicals). It extrudes a plastic tube (“parison”), then blows compressed air into it to fit a custom mold. EBM handles large sizes (up to 20L) and is flexible for unique designs.

-

- Stretch Blow Molding (SBM): Used exclusively for PET bottles, SBM stretches the preform before blowing it into the mold. This process enhances the plastic’s strength, clarity, and barrier properties—why your favorite soda or water bottles look so crisp and hold up to transportation.

For brands needing ultra-precise bottles (like medical-grade containers), combining these techniques with quality checks (e.g., measuring wall thickness) ensures every bottle meets your standards.

3. The Custom Plastic Bottle Production Process

Creating custom plastic bottles is a collaborative, step-by-step journey—designed to turn your ideas into a usable product:

- Needs Assessment: First, we work with you to understand your product (e.g., liquid vs. solid, hot vs. cold fill), target audience, and regulatory needs (e.g., FDA compliance for food). This ensures the bottle works for your specific use case.

- Design & Prototyping: Using 3D modeling, we draft a custom design (shape, color, logo placement) and create a physical prototype. You’ll test it for grip, pouring ease, and aesthetics—we refine until it’s perfect.

- Material Selection: Based on your product and goals, we pick the best plastic (e.g., PET for beverages, HDPE for chemicals) to balance performance and cost.

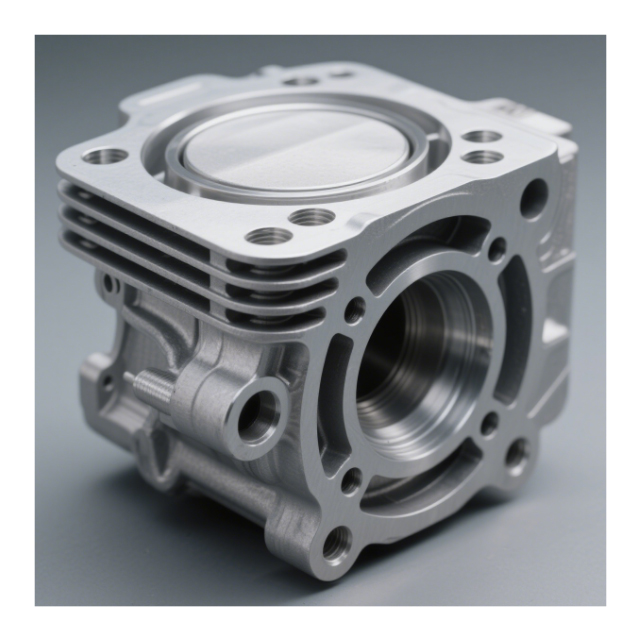

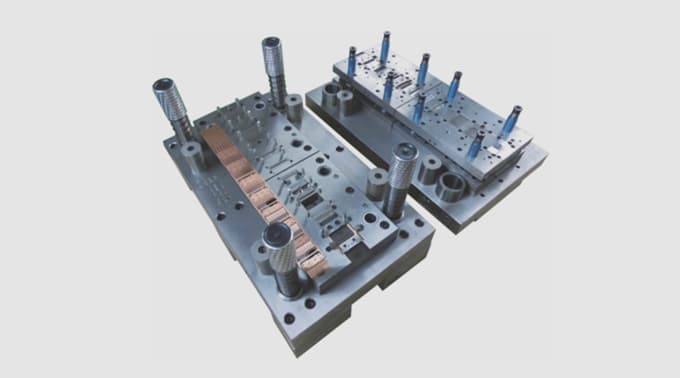

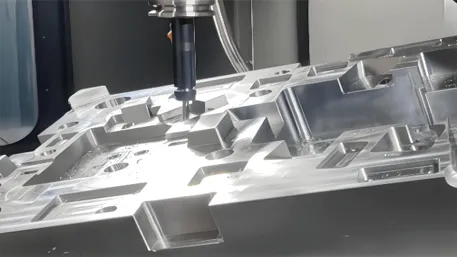

- Mold Creation: Custom molds are crafted with precision machining—every curve, thread, or logo is engraved to match your design. This step is critical for consistency in mass production.

- Production: We use injection or blow molding (whichever fits your design) to create the bottles, with real-time monitoring to avoid defects.

- Quality Testing: Bottles are checked for leaks, structural strength, and dimensional accuracy. For food/medical products, we run additional safety tests.

- Finishing & Delivery: Logos are printed (via screen, digital, or pad printing), and bottles are packaged (bulk or custom wrapping) before shipping.

This process ensures transparency—you’re involved every step of the way, so the final product matches your vision.

4. Key Features of Custom Plastic Bottles

What makes custom plastic bottles stand out from generic options? It’s all in the features tailored to your brand:

- Design Flexibility: Choose any shape (square, curved, branded silhouettes), color (matching your brand palette), or finish (matte, glossy, textured). Add embossed logos or grip indentations to make your bottle memorable.

- Durability: Depending on the material, custom bottles resist drops, chemicals, or heat. HDPE bottles handle industrial use, while PP stands up to hot fills—no more cracked or leaking containers.

- Seal Security: Custom closures (tamper-evident caps, leak-proof lids, pumps for lotions) keep contents fresh and safe. For pharmaceuticals, this means meeting strict safety regulations; for food, it means longer shelf life.

- Sustainability: Opt for recyclable materials (PET, HDPE) or post-consumer recycled (PCR) plastic to reduce waste. We also design bottles for reuse (e.g., refillable 日化 containers) to align with eco-friendly brands.

- Size Versatility: From 5ml sample bottles to 20L industrial containers, custom sizes fit your product’s usage—no more wasting space or forcing customers to buy more than they need.

5. Equipment: The Backbone of Quality Custom Bottles

High-quality custom plastic bottles depend on advanced equipment that ensures precision and efficiency:

- Injection Molding Machines: These use CNC systems to control temperature and pressure, producing uniform preforms or small bottles. They handle high volumes and work with all plastic types.

- Blow Molding Machines: EBM machines extrude parisons and blow them into molds, while SBM machines stretch PET preforms for clarity. Both have adjustable settings for different bottle sizes.

- Mold-Making Tools: CNC milling and EDM (Electrical Discharge Machining) create molds with intricate details—even tiny logos or thread patterns are replicated perfectly.

- Quality Control Equipment: Leak testers use air pressure to detect defects, while CMMs (Coordinate Measuring Machines) check dimensions. Visual inspection systems spot scratches or color inconsistencies.

This equipment ensures every bottle is consistent—no two are different, so your brand looks professional.

6. Production: Balancing Quality, Speed, and Sustainability

We prioritize three things in custom plastic bottle production: quality, speed, and sustainability. Here’s how:

- Quality First: We source resin from trusted suppliers and test every batch for purity. In-line checks (sampling bottles every 30 minutes) catch defects early, and final audits ensure 100% compliance.

- Efficient Timelines: Prototyping takes 1–2 weeks, mold creation 3–4 weeks, and production 2–3 weeks. For simple designs (e.g., adjusting an existing mold), we can deliver in 3–4 weeks total.

- Sustainability: We optimize material usage to reduce waste (excess plastic is recycled), use energy-efficient machines, and offer PCR plastic options. Our goal is to help you meet your sustainability targets without sacrificing quality.

7. Applications: Custom Plastic Bottles for Every Industry

Custom plastic bottles adapt to nearly every sector—their versatility makes them indispensable:

- Food & Beverage: PET bottles for juices, water, or sauces; PP for hot-fill soups or syrups. Clear designs showcase products, and food-safe materials meet FDA standards.

- Personal Care & 日化: HDPE bottles for shampoos, lotions, or cleaning products. Custom shapes (pump bottles, squeeze tubes) enhance usability, and branded colors build loyalty.

- Pharmaceuticals: PP or PET bottles for medications, vitamins, or medical supplies. Non-toxic, moisture-resistant materials protect drugs, and tamper-evident caps ensure safety.

- Industrial: Thick-walled HDPE or PVC bottles for chemicals, lubricants, or solvents. They resist leaks and harsh ingredients, keeping workers safe.

- Promotions: Small 10–50ml sample bottles with branded logos—perfect for events or product launches to attract new customers.

In every industry, the advantage is clear: custom plastic bottles don’t just package your product—they enhance it.

Frequently Asked Questions (FAQs) About Custom Plastic Bottles

- What’s the minimum order quantity (MOQ) for custom plastic bottles?

Our MOQ starts at 5,000 units for standard designs, but we offer flexible small-batch options (1,000–3,000 units) for new brands or limited-edition products. Contact us to discuss your volume needs.

- Can I get a sample before mass production?

Absolutely! We create physical prototypes (1–5 samples) so you can test design, fit, and functionality. We’ll revise the prototype until it meets your expectations.

- Are custom plastic bottles recyclable?

Yes—most materials (PET, HDPE, PP) are 100% recyclable. We also offer PCR plastic bottles (made from recycled plastic) for brands focused on sustainability.

- How do I add my logo to the bottle?

We offer screen printing (for bold, durable designs), digital printing (for full-color graphics), pad printing (for curved surfaces), and pressure-sensitive labels. Our team will help you choose the best method for your logo and material.

- Do you offer food-safe or medical-grade bottles?

Yes—we specialize in FDA-compliant (food-safe) and ISO-certified (medical-grade) bottles. All materials are tested to meet strict safety standards for contact with food, drugs, or medical supplies.

Ready to Create Your Custom Plastic Bottles?

Whether you’re launching a new product, updating packaging, or need specialized bottles for your industry, we’re here to help. Our team will guide you from design to delivery, ensuring your custom plastic bottles align with your brand, budget, and goals.

Leave us a message today with your requirements (product type, desired size, design ideas, and volume), and we’ll send a personalized quote and design proposal within 24 hours. Let’s turn your packaging vision into a product your customers will love!