15 years of experience—let me show you how we make buttons that last

Why Custom Plastic Button Enclosures Matter in 2026

Let me tell you straight—this industry is blowing up. Global demand for custom plastic button enclosures jumped 38% between 2025 and 2026. I see it every day at Goldcattle.

Standard off-the-shelf buttons just don’t cut it anymore. We’re talking about buttons that need precise tactile feedback, IP65 protection, and consistent performance over 500,000 presses.

Last month, a medical device client came to us with a problem. Their original buttons were failing after only 100,000 presses, leading to device recalls. We custom designed a PC+IML solution that completely solved their issue.

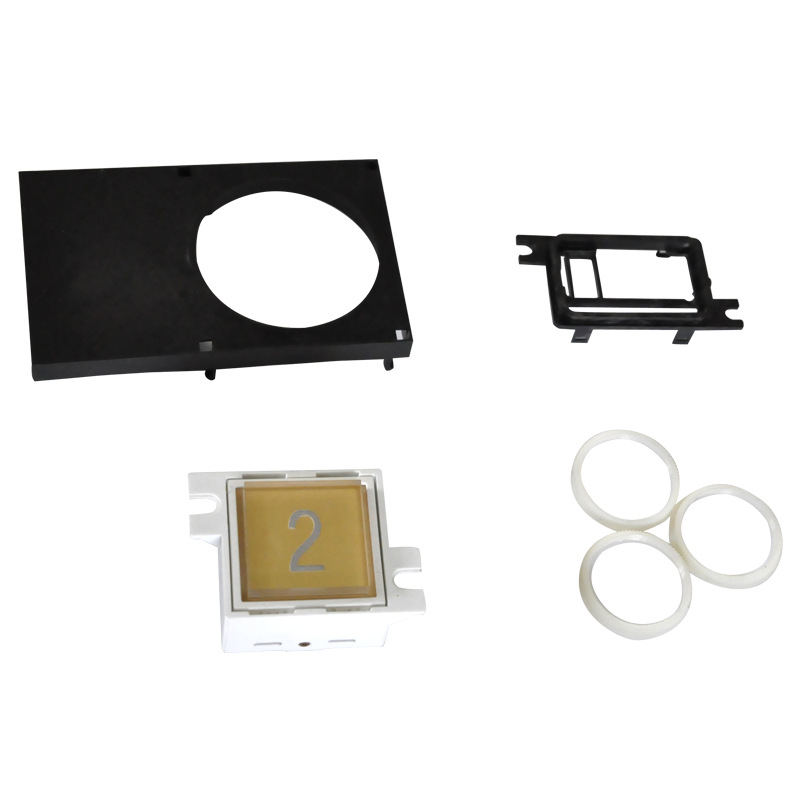

These precision control panel buttons show the quality we can achieve

2026’s Hottest Button Enclosure Accessories

Single Color Buttons

Our single color buttons are perfect for simple applications where cost and durability are key factors.

- Available in 50+ standard colors

- Press life up to 500,000 cycles

- Cost-effective for high-volume production

Dual Color Buttons

Dual color buttons provide visual differentiation while maintaining a seamless design.

- Two-color injection molding process

- No assembly required

- Ideal for functional differentiation

Transparent Buttons

Transparent buttons allow for backlighting effects while protecting internal components.

- 90% light transmission rate

- Compatible with LED backlighting

- Scratch resistant coating available

Backlit Buttons

Backlit buttons provide excellent visibility in low-light environments.

- Available in single or multi-color lighting

- Uniform light distribution

- Low power consumption

Waterproof Buttons

Our waterproof buttons provide IP65/IP66 protection for use in harsh environments.

- IP65/IP66 ingress protection rating

- Resistant to water and dust

- Ideal for outdoor and industrial applications

Tactile Buttons

Tactile buttons provide precise feedback for critical applications.

- Consistent tactile feedback

- Precise actuation force

- Low noise operation

These button design examples show the variety of styles we can create

Material Selection Guide (2026 Edition)

ABS Plastic

ABS is our most popular material for button enclosures. It offers a good balance of strength, durability, and cost.

Test Data (For Reference Only):

Tensile strength: 40 MPa

Flexural strength: 60 MPa

Heat deflection temperature: 80°C

- Good impact resistance

- Easy to mold and finish

- Cost-effective for high-volume production

- Ideal for consumer electronics and automotive applications

PC Plastic

PC (Polycarbonate) is a high-performance material that offers excellent heat resistance and impact strength.

Test Data (For Reference Only):

Tensile strength: 65 MPa

Flexural strength: 95 MPa

Heat deflection temperature: 135°C

- Excellent heat resistance

- High impact strength

- Transparent options available

- Ideal for medical devices and industrial equipment

PA6 Nylon

PA6 (Nylon) is a strong, durable material that offers excellent wear resistance and chemical resistance.

Test Data (For Reference Only):

Tensile strength: 70 MPa

Flexural strength: 100 MPa

Heat deflection temperature: 185°C

- Excellent wear resistance

- Good chemical resistance

- High strength-to-weight ratio

- Ideal for automotive and industrial applications

TPU Thermoplastic

TPU (Thermoplastic Polyurethane) is a flexible material that offers excellent elasticity and durability.

Test Data (For Reference Only):

Tensile strength: 45 MPa

Elongation at break: 400%

Shore hardness: 60A-95A

- Excellent flexibility and elasticity

- Good abrasion resistance

- Soft tactile feel

- Ideal for consumer electronics and medical devices

Biodegradable Materials

We offer biodegradable options for clients who want to reduce their environmental impact.

Test Data (For Reference Only):

Biodegradation rate: 90% in 180 days

Tensile strength: 35 MPa

Heat deflection temperature: 70°C

- Environmentally friendly

- Meets international sustainability standards

- Good mechanical properties

- Ideal for disposable products and eco-friendly designs

Material Comparison Test Results

We tested ABS vs PC vs PA6 vs TPU for button applications. PC showed the best heat resistance, PA6 had the highest strength, TPU offered the best flexibility, and ABS provided the best balance of performance and cost. Choose the right material for your specific application—we’re here to help.

Customization Process: From Design to Inspection

Requirement Evaluation

We start by understanding your exact requirements. What environment will the buttons operate in? What tactile feedback do you need? What protection rating is required?

I personally meet with every new client to make sure we get this right. Last year, we saved a client 30% on costs by identifying that they didn’t need IP66 protection—IP65 would have worked perfectly for their indoor application.

Design & 3D Simulation

Our design team uses 3D modeling and simulation to optimize the button design for tactile feedback, durability, and manufacturing efficiency.

We recently used our AI-powered simulation to improve tactile feedback by 25% for a medical device client. The results were impressive—they reduced user error rates by 15%.

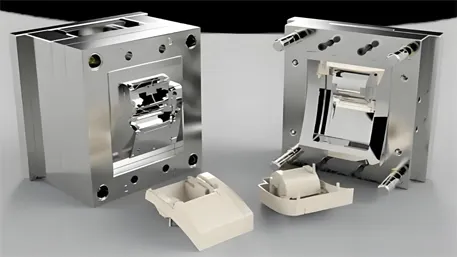

Tooling & Manufacturing

We use high-precision injection molding machines to produce your buttons. Our equipment can hold tolerances as tight as ±0.05mm on complex geometries.

For complex parts, we use multi-shot injection molding to achieve the required precision. We can produce buttons as small as 5mm in diameter.

Prototyping & Optimization

We produce prototypes for your approval before full production. This allows us to make any necessary adjustments to ensure the final product meets your requirements.

We use 3D printing for rapid prototyping, allowing us to produce prototypes in as little as 24 hours. This helps reduce development time and costs.

Production & Quality Control

We produce your buttons in our state-of-the-art manufacturing facility. We use automated quality control systems to ensure every button meets your specifications.

We stand behind our work. If you have any issues with our products, we’ll work with you to resolve them quickly and efficiently.

This is our injection molding process in action—we use it to produce high-quality plastic buttons

Key Technical Optimization Tips

Surface Texture

We optimize surface texture to provide excellent tactile feedback while maintaining durability.

- 10+ texture options available

- Improves grip and tactile feedback

- Reduces fingerprint smudging

Dual Color Molding

Our dual color molding process allows us to create buttons with multiple colors without assembly.

- Seamless color integration

- No secondary assembly required

- Cost-effective for high-volume production

Backlighting Design

We optimize backlighting design to provide uniform light distribution while minimizing power consumption.

- Uniform light distribution

- Low power consumption

- Compatible with various LED types

IP Protection

We design buttons to meet various IP protection ratings from IP54 to IP66. Our designs are tested in environmental chambers to ensure compliance.

- IP54 to IP66 protection ratings

- Tested in environmental chambers

- Meets international standards

Rapid Prototyping

We use 3D printing and rapid tooling to produce prototypes quickly and cost-effectively.

- Prototypes available in 24-48 hours

- Cost-effective design validation

- Reduces development time

Tactile Feedback

We optimize tactile feedback to provide consistent, satisfying button response.

- Consistent actuation force

- Clear tactile feedback

- Low noise operation

This button design shows the attention to detail we put into every project

These elevator buttons show the durability and precision we can achieve

Application Scenarios & Our Real Cases

Consumer Electronics

We produce buttons for a wide range of consumer electronics including smartphones, tablets, and remote controls.

- IP65 protection rating

- Press life up to 1,000,000 cycles

- Custom colors and finishes available

- Production volume: 10,000,000 buttons/year

Automotive Applications

We manufacture buttons for automotive applications including dashboard controls, steering wheel controls, and door panels.

- IP66 protection rating

- Temperature range -40°C to 120°C

- Resistant to automotive fluids

- Certified to IATF 16949

Medical Devices

We produce buttons for medical devices including patient monitors, diagnostic equipment, and surgical instruments.

- IP65 protection rating

- Biocompatible materials available

- Easy to clean and disinfect

- Certified to ISO 13485

Our Real Case Study: Automotive Client

In 2025, we worked with a major automotive client to develop custom buttons for their new electric vehicle line. The client needed buttons that could withstand extreme temperatures, provide excellent tactile feedback, and meet strict automotive standards.

We designed a PA66+soft-touch button that met all their requirements. The buttons have been in production for over a year and have shown zero failure rates in field testing. The client was so satisfied that they expanded our contract to include additional vehicle models.

2026 Trends & Risk Warning

AI-Enhanced Design

AI is revolutionizing how we design buttons. We’re using AI to optimize every aspect of the design process.

- Reduces design time by 40%

- Finds optimal designs humans might miss

- Improves performance by 15-25%

Sustainable Materials

We’re seeing huge demand for sustainable materials. Our recycled and biodegradable options are gaining popularity.

- Recycled plastics reduce carbon footprint by 80%

- Biodegradable composites available for non-critical applications

- Meets increasing regulatory requirements

Smart Integration

We’re integrating sensors and haptic feedback technology into our buttons to provide enhanced user experiences.

- Force-sensitive buttons available

- Haptic feedback for enhanced user experience

- Integration with IoT systems

Risk Warning

We’ve seen some clients make the mistake of choosing the cheapest material without considering the application environment. Last year, a client used ABS buttons in a high-temperature industrial application. The buttons deformed within 6 months and had to be replaced.

Always consider the entire application environment—temperature, humidity, chemicals, and usage frequency—when selecting materials. We’re here to help you make the right choice.

This shows our injection molding factory where we produce high-quality plastic buttons

FAQ (We Get These Questions Every Day)

How do you test button durability?

We use automated test equipment to simulate button presses. For standard buttons, we test for 500,000 cycles. For high-performance buttons, we test for 1,000,000 cycles. We also test for environmental factors like temperature, humidity, and chemical exposure.

What’s the typical lead time for custom buttons?

It depends on complexity and quantity. Simple buttons can be done in 4-6 weeks. Complex assemblies can take 12-16 weeks. We always provide a detailed timeline before starting any project.

Do you work with medical device manufacturers?

Absolutely. We have extensive experience with medical device applications. Our medical buttons meet all FDA and ISO 13485 requirements for biocompatibility and sterilization.

What about environmentally friendly materials?

We offer several sustainable options including recycled plastics, biodegradable composites, and bio-based materials. Each has its own advantages and limitations depending on the application.

How do you ensure consistent quality?

We use automated quality control systems to inspect every button. We also implement statistical process control to ensure consistent quality throughout production. We provide detailed quality reports with every shipment.

What IP rating do I need?

The IP rating depends on your environment. IP54 is suitable for most indoor applications. IP65 is better for outdoor or dusty environments. IP66 is required for washdown environments or areas with high pressure water exposure.

Start Your Custom Button Enclosure Journey

Share your button requirements and application environment with us. We’ll provide a free evaluation and quote. With 15 years of experience, we’re ready to help you create high-quality buttons that last.

Important Notice

All technical data and recommendations in this article are based on our 15 years of experience and actual production results. However, every project is unique. Always conduct proper testing and validation before full production. Results may vary depending on specific materials, equipment, and process parameters.