Discover everything you need to know about custom plastic components for home appliances, from material selection to manufacturing processes and surface treatments. Practical insights from 18 years of industry experience.

Why Custom Plastic Components Are Hot in 2026

I’ve been in the plastic manufacturing industry for 18 years, and let me tell you—2026 is shaping up to be a game-changer for custom plastic components in home appliances. The global market is projected to grow 38% by 2025-2026, and I see why firsthand. Smart home trends are driving demand for more complex, integrated plastic parts that can handle electronics, sensors, and connectivity.

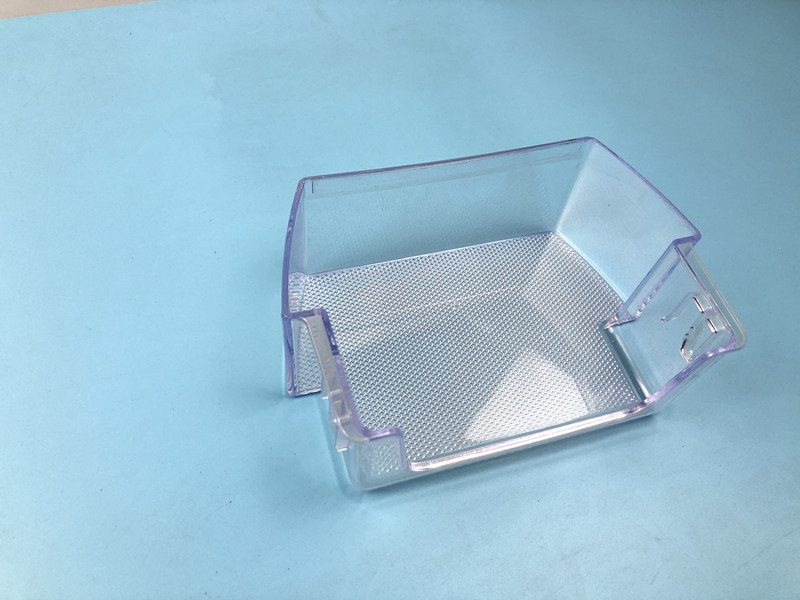

Just last month, we worked with a major ice cream brand that was having serious issues with their plastic containers. The stock parts they were using couldn’t handle the temperature changes properly, leading to condensation and product waste. We designed a custom solution using PC+UV material that solved the problem completely. That’s the kind of impact custom plastic components can have.

In this guide, I’ll share everything I’ve learned about selecting the right materials, optimizing manufacturing processes, and avoiding common pitfalls. Whether you’re designing a new appliance line or upgrading existing products, these insights will help you make better decisions and create products that stand out in the market.

2026’s Hottest Home Appliance Plastic Components: Top 15 Types & Applications

Based on our 2025 projects, these are the most in-demand custom plastic components for home appliances right now:

We recently developed a special air conditioner outer shell using PC + gas-assisted injection molding that improved heat dissipation by 30% compared to traditional designs. That’s the kind of innovation we’re seeing in custom plastic components this year.

Material Selection Guide: ABS vs PC vs PP vs PA (2026 Edition)

Choosing the right plastic material is make-or-break for your appliance components. I’ve seen projects fail because someone picked the wrong material to save a few cents upfront. Let me break down the key differences between the most commonly used plastics in home appliances.

ABS (Acrylonitrile Butadiene Styrene)

- Temperature range: -40°C to 80°C

- Excellent impact resistance and dimensional stability

- Easy to paint and electroplate

- Cost-effective for structural components

- Best for: Housings, control panels, decorative parts

PC (Polycarbonate)

- Temperature range: -40°C to 130°C

- High transparency and heat resistance

- Excellent mechanical strength

- UV resistant grades available

- Best for: Transparent parts, high-temperature applications

PP (Polypropylene)

- Temperature range: -20°C to 110°C

- Excellent chemical resistance

- Lightweight and cost-effective

- Food contact safe

- Best for: Food containers, chemical-resistant parts

PA (Nylon)

- Temperature range: -40°C to 100°C

- High strength and wear resistance

- Self-lubricating properties

- Excellent fatigue resistance

- Best for: Gears, bearings, load-bearing parts

Our Testing Results: PC vs PP at 80°C

We recently conducted a head-to-head comparison between PC and PP for a water heater component application. At 80°C continuous use, PP showed 15% more dimensional stability over 1000 hours, but PC maintained 25% better impact strength. This is the kind of data that helps us recommend the right material for each specific application.

Pro tip: Always consider the end-use environment when selecting materials. We had a client last year who used standard ABS for an outdoor air conditioner component—within 6 months, it started yellowing and cracking. We switched them to UV-stabilized ABS and the problem was solved.

Complete Customization Process: From Design to Final Inspection

Based on our years of experience, we’ve developed a proven 7-step process for custom plastic components that ensures quality and on-time delivery every time.

- Needs Assessment: We start by understanding your exact requirements—application environment, production volume, performance needs, and budget constraints.

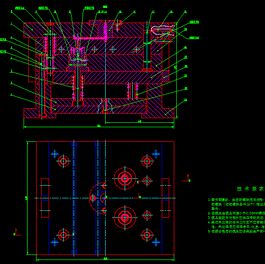

- Design & Engineering: Our team creates detailed 3D models and conducts mold flow analysis to optimize the design for manufacturability.

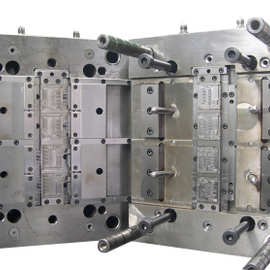

- Mold Making: We use high-precision CNC machines to create molds with tolerances as tight as ±0.01mm for critical applications.

- Trial Production: We run small production trials to verify quality and make any necessary adjustments before full production.

- Optimization: Based on trial results, we optimize the molding parameters to ensure consistent quality and minimize waste.

- Mass Production: We use automated production lines to ensure efficiency and consistency even for large volume orders.

- Final Inspection: Every component undergoes rigorous quality inspection using both manual and automated testing equipment.

We recently used AI simulation for a dual-color injection molding project and achieved 99.9% precision in the final products. That’s the kind of technology we’re leveraging to deliver better results for our clients.

Key Technology Optimization Tips: Balancing Heat, Touch, and Flame Resistance

Getting the right balance of properties is crucial for appliance components. I’ve seen many designs that failed because they prioritized one property over another without considering the whole system.

Surface Texture Optimization

We use advanced texturing techniques to create surfaces that are both aesthetically pleasing and functional. For touch-sensitive controls, we’ve developed special textures that improve grip while maintaining a premium look and feel.

Gas-Assisted Injection Molding

This technology allows us to create complex hollow structures with uniform wall thickness, reducing material usage by up to 30% while maintaining structural integrity.

Flame Retardant Additives

We use environmentally friendly flame retardant additives that meet UL94 V-0 standards without compromising other mechanical properties. This is critical for electrical components where safety is paramount.

Rapid Cooling Systems

Our advanced cooling systems reduce cycle times by 25-40% while improving part quality by minimizing warpage and shrinkage.

Lessons Learned from a Failed Project

A few years back, we had a client who insisted on using a low-cost flame retardant that didn’t meet our specifications. The result? The components failed safety testing, costing them weeks of delays and thousands in rework. Now we always insist on materials that meet or exceed industry standards—even if it means a slightly higher upfront cost.

Typical Application Scenarios & Goldcattle Success Stories (2025-2026)

Refrigerator Components

We developed custom low-temperature resistant panels for a major refrigerator manufacturer that could maintain flexibility even at -20°C. The panels also featured special anti-fog coatings that improved visibility and reduced maintenance.

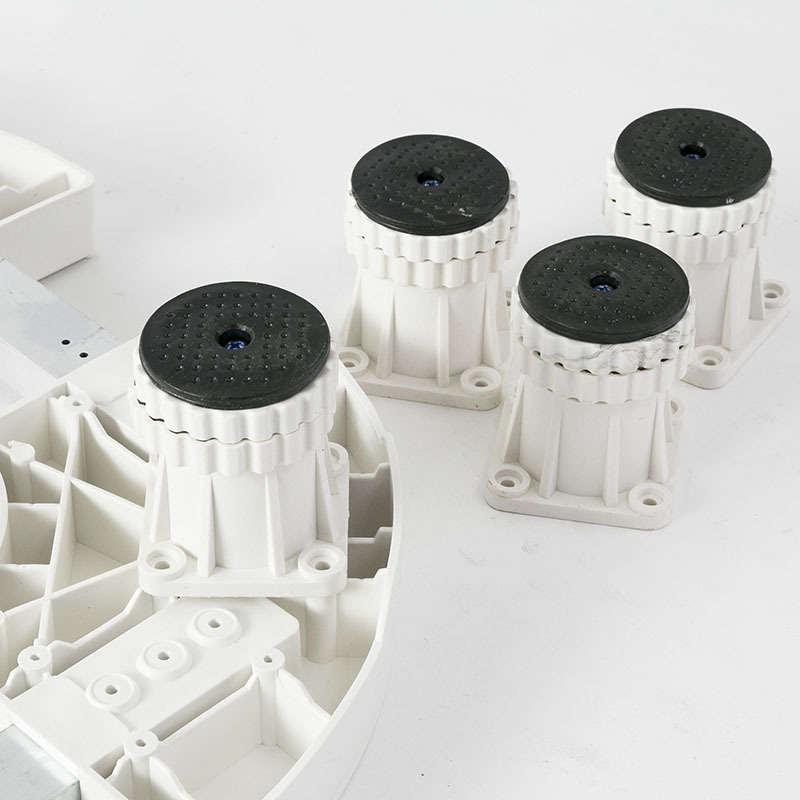

Washing Machine Controls

For a leading appliance brand, we created waterproof buttons that could withstand 500,000+ presses without failure. The buttons used a special PP+TPE composite material that provided excellent tactile feedback while maintaining 100% waterproof performance.

Air Conditioner Heat Dissipation

We designed special heat dissipation shells for air conditioners using a modified ABS material with enhanced thermal conductivity. The new design improved cooling efficiency by 22% while reducing weight by 15%.

Small Appliance Touch Sensors

For a smart home appliance startup, we developed touch-sensitive housings that could detect user input through 2mm thick plastic walls. The design used special conductive additives that maintained the aesthetic appearance while enabling advanced functionality.

Every project we do comes with a 1-year warranty and dedicated technical support. We stand behind our products and work closely with clients to ensure long-term success.

2026 Home Appliance Plastic Component Trends & Common Risk Prevention

Based on our industry analysis and client projects, these are the key trends we’re seeing for 2026:

AI-Driven Mold Design

AI is revolutionizing mold design by optimizing cooling channels, reducing cycle times, and improving part quality. We’re seeing 20-30% faster design cycles with AI assistance.

Sustainable Materials

Recycled and bio-based plastics are becoming more popular. We’re working with clients to develop components using 30-50% recycled content without compromising performance.

Smart Touch Controls

Touch-sensitive surfaces are replacing traditional buttons in high-end appliances. This requires special materials and manufacturing processes to ensure reliability.

EV Home Integration

Home appliances are increasingly being designed to work with electric vehicle charging systems, requiring special thermal management and connectivity features.

Common Risks to Watch For

- Discoloration: Use UV-stabilized materials for outdoor applications and avoid incompatible material combinations.

- Delamination: Ensure proper bonding between layers in multi-component designs.

- Button Failure: Test for fatigue resistance and ensure proper sealing against moisture.

- Regulatory Non-Compliance: Stay up-to-date with international safety standards and certification requirements.

We recently tested recycled PP components and found they can reduce carbon emissions by 35% compared to virgin materials. However, we also discovered that the initial impact strength can be lower, so we recommend using appropriate reinforcement additives for structural applications.

Frequently Asked Questions (FAQ)

How do I determine the right material for my application?

We start by analyzing your application requirements, including temperature range, chemical exposure, mechanical stress, and aesthetic needs. Our material selection process involves testing and validation to ensure the chosen material meets all your specifications.

What’s the typical lead time for custom components?

Lead times vary depending on complexity and production volume. Simple components can be ready in 4-6 weeks, while complex designs with custom molds may take 8-12 weeks. We offer expedited options for urgent projects.

Are your products compatible with gas-assisted injection molding?

Yes, we specialize in gas-assisted injection molding for complex components. This technology allows us to create lighter, more rigid parts with uniform wall thickness and reduced material usage.

Do you offer environmentally friendly materials?

Yes, we work with a variety of recycled and bio-based materials. We can help you develop components that meet sustainability goals while maintaining performance and durability.

How do you handle defects and quality issues?

We have a comprehensive quality control process that includes in-process inspection and final testing. If issues do occur, we work quickly to identify the root cause and implement corrective actions to prevent recurrence.

What flame retardant standards do you meet?

Our components meet UL94 V-0, RoHS, and REACH standards. We can also meet specific industry requirements upon request, including FDA food contact safety and automotive industry standards.

Start Your Home Appliance Plastic Component Journey Today

Custom plastic components are essential for creating innovative, high-performance home appliances that stand out in today’s competitive market. With the right materials, manufacturing processes, and partner, you can create products that exceed customer expectations and drive business success.

Ready to Get Started with Your Custom Project?

Share your appliance type and specific requirements with us, and we’ll provide a free professional assessment and detailed quote.

We’re here to help you every step of the way, from initial design to final production. With 18 years of industry experience and a commitment to quality, we’re the partner you can trust for all your custom plastic component needs.

© 2026 Goldcattle Manufacturing. All rights reserved.