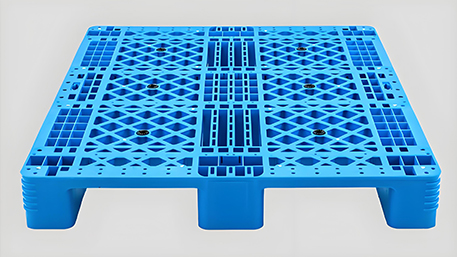

Plastic pallet inserts are key components that enhance the performance and functionality of plastic pallets by embedding them in specific materials or structures to provide greater load-bearing capacity, durability, or other special properties. They are widely used in logistics, warehousing, food processing, pharmaceutical industry and other fields, is an indispensable part of modern supply chain management.

1.Plastic pallet insert production process

Design planning: according to customer demand and pallet use environment, design the shape, size and material of the insert.

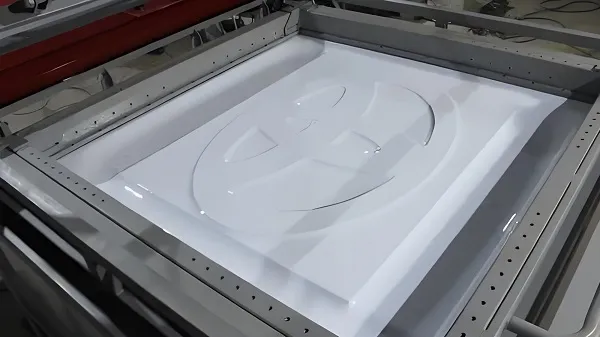

Mold manufacturing: according to the design drawings, manufacturing molds for the production of inserts.

Raw Material Preparation: Select plastic raw materials that meet the requirements, such as high-density polyethylene (HDPE), polypropylene (PP) or copolymerized polypropylene (EPS30R).

Injection/blow molding: The raw material is heated to a molten state and then injected into the mold at high pressure to be molded by the injection or blow molding process.

Cooling and shaping: The molten plastic is cooled and hardened in the mold to form the final shape of the insert.

Post-processing: The inserts are trimmed and deburred to ensure that they meet the quality requirements.

Quality Inspection: The inserts are inspected in terms of size, appearance, performance, etc. to ensure that they are qualified.

2.Plastic pallet inserts customization

Demand communication: Communicate with customers to understand the specific use of the pallet, load-bearing requirements, the use of the environment and so on.

Program development: according to customer needs, develop the design of inserts, including shape, size, material and so on.

Sample production: according to the design scheme, make samples for customers to confirm.

Mass production: After the customer confirms the samples, mass production will be carried out.

After-sales service: Provide after-sales service such as installation guidance and performance consultation of inserts.

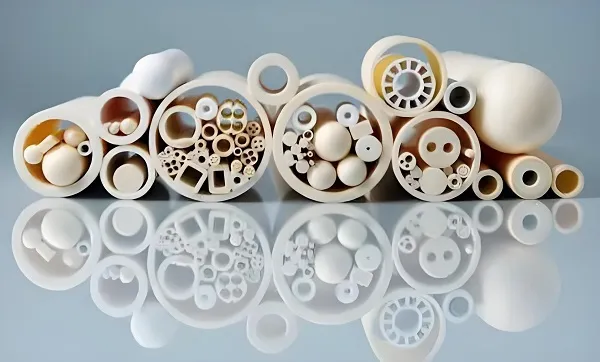

3.Plastic pallet insert material

Material:

High density polyethylene (HDPE)

Polypropylene (PP)

Copolymerized polypropylene (EPS30R)

High polymer polyethylene (UHBMPE)

Characteristics:

High density polyethylene (HDPE):

Stable chemical function, corrosion resistance.

Good insulation.

High impact strength, suitable for use in cold storage, low temperature resistance of minus 30 degrees.

Polypropylene (PP):

Translucent colorless solid, odorless and non-toxic.

Light density, is one of the lightest general-purpose plastics.

Corrosion resistance, high tensile strength.

Copolymerized Polypropylene (EPS30R):

High strength, steel, good toughness.

Better cold and weather resistance, especially excellent in low temperature conditions.

Chemically stable, not easy to age.

High polymer polyethylene (UHBMPE):

Strong load-bearing capacity, long-term use of dynamic load up to 2 tons or more.

Wear-resistant, impact-resistant.

Good chemical stability, adapt to a variety of harsh environments.

4. Characteristics of plastic pallet inserts of different materials

Product:

HDPE inserts

PP inserts

EPS30R inserts

UHBMPE inserts

Data:

HDPE insert:

Impact strength: high

Low temperature resistance: -30 ℃ below can still maintain good performance

Service life: long

PP inserts:

Density: 0.90g/cm³

Tensile strength: 30MPa

Aging resistance: general, easy to aging in outdoor environment

EPS30R inserts:

Toughness: good

Cold resistance: excellent, not easy to deform under low temperature conditions

Cost: Higher, due to material extraction process limitations

UHBMPE inserts:

Load-bearing capacity: strong, long-term use of dynamic load up to 2 tons or more

Abrasion resistance: high

Chemical stability: good, adapt to a variety of harsh environments

Customized plastic pallet inserts FAQ

Q1:How long does it take to customize plastic pallet inserts?

A: The customization time varies according to the customer’s demand and order quantity, generally it takes several weeks from design to mass production.

Q2: How to calculate the price of customized plastic pallet inserts?

A: The price is calculated according to the shape, size, material, quantity and other factors of the inserts, the specific price needs to be determined after communicating with customers.

Q3: Does customized plastic pallet inserts support return?

A: Since the customized products are customized according to the customer’s demand, so generally do not support the return of goods. However, we can provide samples for customer confirmation to ensure that the final product meets customer requirements.

Q4: What are the advantages of customized plastic pallet inserts?

A: Customized inserts can be individually designed according to customer needs to meet special usage environment and performance requirements, and improve the overall performance and durability of the pallet.

Through the above introduction, I believe you have a deeper understanding of customized plastic pallet inserts. If you have any questions or needs, please feel free to contact us.