- Micron-level dimensional control: Based on ISO 20457 standard, critical dimensional tolerance can be controlled within ±0.05mm, surface roughness Ra≤0.4μm, far exceeding industry average level

- Material performance optimization: Provide a wide selection of high-performance materials from PP, ABS, PC to PEEK according to different application scenarios, ensuring optimal balance between product performance and cost

- Complex structure realization: Capable of manufacturing thin-walled structures (minimum wall thickness 0.3mm), complex curved surfaces, and internal channel designs that are difficult to achieve with traditional processes

Professional Team: Engineering Team with Over 15 Years of Industry Experience

- Chief Mold Engineer Chen Gang: 20 years of plastic mold design experience, has led multiple automotive parts and medical device mold projects, proficient in Moldflow CAE analysis

- Material Expert Lin Xiaohua: 18 years of material science background, focusing on plastic material selection and performance optimization, familiar with processing characteristics of various engineering plastics

- Process Engineer Wang Jianguo: 16 years of injection molding process experience, specialized in process parameter optimization and quality problem solving, has provided technical support for many well-known enterprises

- Structural optimization suggestions: Conduct strength analysis and molding feasibility evaluation of product structure according to ISO 20457 standard

- Material selection guidance: Recommend the most suitable plastic materials based on product usage environment and performance requirements

- Mold design solution: Provide detailed mold design plan and cost estimation to ensure smooth project progress

Authoritative Standards: Strictly Following International Quality Standard Systems

Material Performance Comparison Table

|

Material Name

|

Density (g/cm³)

|

Tensile Strength (MPa)

|

Flexural Strength (MPa)

|

HDT (1.82MPa, °C)

|

Impact Strength (kJ/m²)

|

Mold Shrinkage (%)

|

Typical Applications

|

|

ABS

|

1.02-1.08

|

35-50

|

50-80

|

80-110

|

15-40 (notched)

|

0.4-0.7

|

Electronic housings, automotive parts, toys

|

|

Polypropylene (PP)

|

0.89-0.91

|

20-30

|

30-50

|

100-120

|

2-5 (notched)

|

1.5-2.5

|

Automotive components, household appliance housings, packaging

|

|

Polycarbonate (PC)

|

1.18-1.20

|

60-70

|

90-110

|

130-140

|

60-80 (unnotched)

|

0.5-0.8

|

Transparent parts, safety helmets, optical components

|

|

Nylon 6 (PA6)

|

1.13-1.15

|

60-90

|

90-120

|

70-90

|

5-20 (notched)

|

0.8-2.5

|

Gears, bearings, electrical connectors

|

|

Nylon 66 (PA66)

|

1.14-1.15

|

70-90

|

100-130

|

75-95

|

5-15 (notched)

|

1.5-2.2

|

Automotive parts, mechanical components

|

|

Acetal (POM)

|

1.41-1.43

|

60-75

|

80-100

|

110-130

|

6-10 (notched)

|

1.2-3.0

|

Precision gears, fasteners, sliding components

|

|

PEEK

|

1.30-1.32

|

90-100

|

130-150

|

340-350

|

8-15 (notched)

|

1.2-1.8

|

Aerospace components, medical implants

|

|

HDPE

|

0.94-0.96

|

20-35

|

25-40

|

60-80

|

20-100 (unnotched)

|

1.5-3.0

|

Chemical tanks, pipes, bottle caps

|

|

Rigid PVC

|

1.3-1.45

|

40-60

|

70-90

|

70-80

|

2-5 (notched)

|

0.2-0.6

|

Pipes, profiles, construction materials

|

Material Selection Guide Table

|

Application Requirement

|

Recommended Materials

|

Key Performance Features

|

Application Examples

|

|

High Strength Requirements

|

PA66, POM, PEEK

|

Tensile strength >70MPa, flexural strength >100MPa

|

Mechanical structural parts, transmission components

|

|

High Toughness Requirements

|

PC, ABS, TPU

|

Impact strength >40kJ/m², elongation at break >50%

|

Protective housings, sports equipment

|

|

High Temperature Resistance

|

PEEK, PPS, LCP

|

HDT >200°C, continuous use temperature >150°C

|

Automotive engine components, electronic parts

|

|

Chemical Resistance

|

PTFE, PP, HDPE

|

Excellent resistance to acids, alkalis, solvents, oils

|

Chemical equipment, piping systems

|

|

Transparency Requirements

|

PC, PMMA, PS

|

Light transmittance >85%, haze <2%

|

Optical components, transparent housings

|

|

Wear Resistance

|

POM, PA66, PTFE

|

Low friction coefficient, small wear rate

|

Gears, bearings, sliding components

|

|

Electrical Insulation

|

PBT, PET, PP

|

Dielectric strength >20kV/mm, volume resistivity >10¹⁴Ω·cm

|

Electronic insulation components, connectors

|

|

Food Contact

|

PP, PE, PC

|

Complies with GB 4806.7-2016, non-toxic and odorless

|

Food packaging, kitchenware, medical devices

|

1. Dimensional Accuracy Standards

- Critical dimensional accuracy: ±0.05mm (TG3 tolerance class), suitable for precision parts with high fitting requirements

- General dimensional accuracy: ±0.15mm (TG5 tolerance class), suitable for most structural parts

- Geometric tolerances: Flatness ≤0.1mm/100mm, perpendicularity ≤0.2mm/100mm, ensuring assembly accuracy

2. Material Performance Standards

- Food contact materials: Complies with GB 4806.7-2016 “Food contact plastic materials and articles”, total heavy metal migration ≤10mg/kg

- Electronic and electrical materials: Meets EU RoHS 2.0 directive, restricting the use of 6 hazardous substances including lead and mercury

- Medical-grade materials: Complies with GB/T 16886 “Biological evaluation of medical devices”, cytotoxicity grade ≤1

3. Surface Quality Standards

- Surface roughness: Ra≤0.8μm (general requirement), Ra≤0.2μm (high-gloss requirement)

- Surface defects: Short shot area ≤0.5mm², flash width ≤0.05mm, bubble diameter ≤0.3mm

- Color consistency: Color difference ΔE≤2.0 (complying with CIE LAB color space standard)

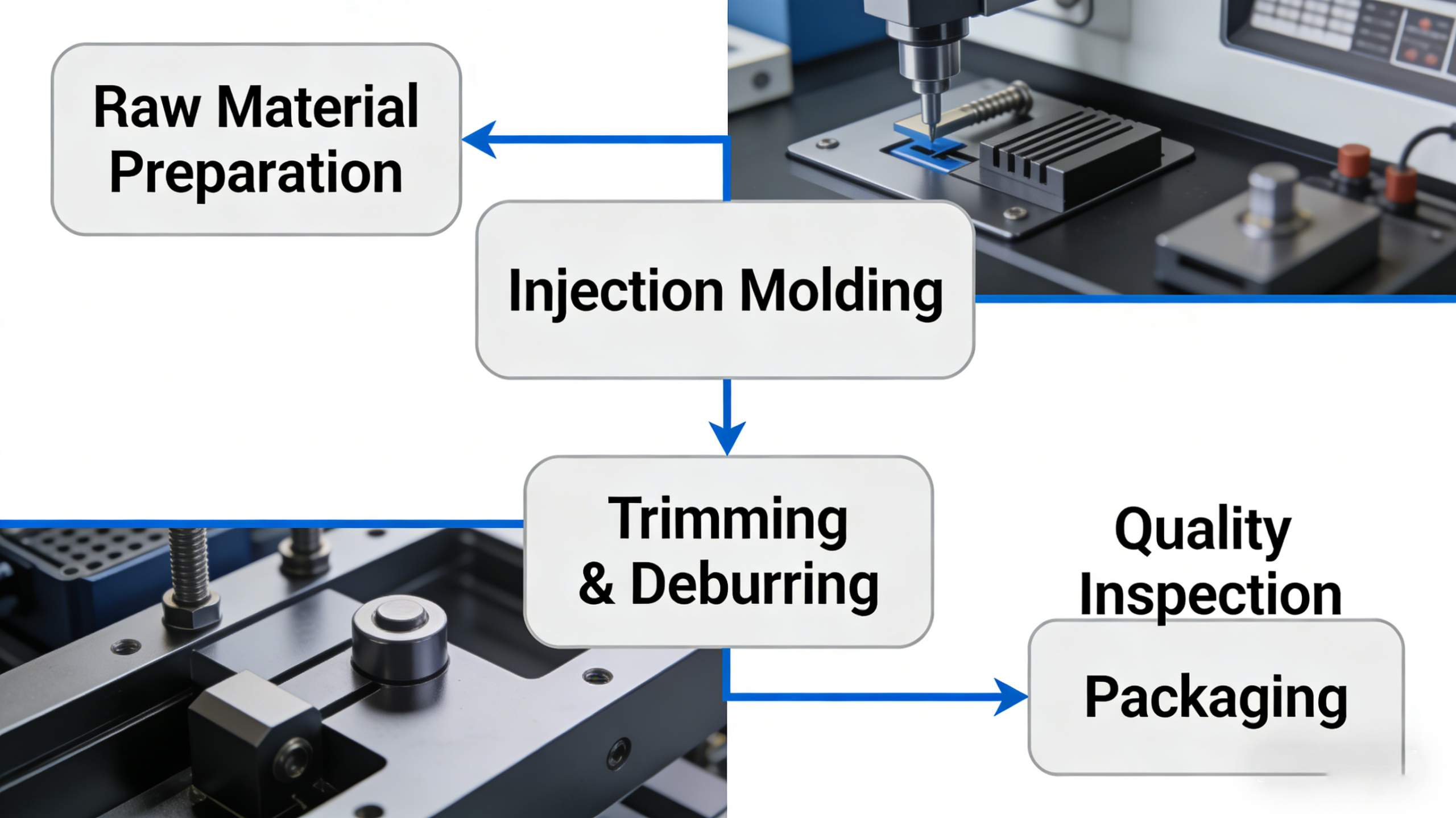

Process Flow: Standardized Six-Step Manufacturing Process

Step 1: Requirement Analysis and DFM Evaluation

- Product structure optimization to avoid molding defects

- Material selection suggestions to balance performance and cost

- Mold design solution to ensure production feasibility

Step 2: Mold Design and Manufacturing

- Design software: Using professional software such as UG, Pro/E, AutoCAD

- CAE analysis: Conducting flow, cooling, and warpage analysis through Moldflow

- Processing equipment: 5-axis machining center with positioning accuracy ≤0.005mm

- Mold materials: Selecting high-quality mold steels such as Cr12MoV, S136, H13 according to production volume

Step 3: Mold Testing and Process Optimization

- Injection molding equipment: Equipped with Haitian, Chen Hsong and other brand injection molding machines with clamping force 50-2000 tons

- Process control: Precisely control temperature, pressure, speed and other parameters to ensure stable product quality

- Quality inspection: Conduct full-dimensional inspection and performance testing on mold test samples

Step 4: Mass Production and Process Control

- Production management: Implement ISO 9001 quality management system with clear operating specifications for each process

- Process monitoring: Real-time monitoring of injection molding parameters, sampling inspection every 2 hours

- Quality traceability: Record production data through MES system to achieve full traceability of product quality

Step 5: Post-Processing and Surface Decoration

- Surface treatment: Polishing, sandblasting, texture, etching, etc.

- Coating processes: Spraying, silk-screen printing, pad printing, hot stamping, etc.

- Assembly services: Provide product assembly and packaging services

Step 6: Quality Inspection and Delivery

- Dimensional inspection: Coordinate measuring machine, projector and other precision testing equipment

- Performance testing: Mechanical property tests such as tensile strength, impact strength, heat distortion temperature

- Environmental testing: Environmental adaptability tests such as high-low temperature cycling, damp heat, salt spray

Quality Assurance: Comprehensive Quality Control System

1. Raw Material Control

- Supplier evaluation: Select high-quality raw material suppliers and establish long-term cooperative relationships

- Incoming inspection: Conduct appearance, density, melt index and other index tests on each batch of raw materials

- Material traceability: Record raw material batch information to achieve quality traceability

2. In-Process Quality Control

- First article inspection: Conduct first article inspection before each batch production to ensure correct process parameters

- Patrol inspection system: Conduct quality checks every 2 hours during production

- Statistical process control: Adopt SPC technology to monitor production process and timely detect and solve problems

3. Finished Product Quality Inspection

- Full-dimensional inspection: 100% inspection for critical dimensions, sampling according to AQL 1.0 for general dimensions

- Appearance inspection: Conduct appearance inspection under standard light source to ensure surface quality

- Performance testing: Conduct corresponding performance tests according to product requirements

Application Cases: Successfully Serving Well-Known Enterprises in Multiple Industries

Case 1: Automotive Component Customization

- Project background: Customizing plastic components around the engine for a well-known automobile manufacturer

- Technical challenges: High temperature resistance (120°C), high strength, complex structure

- Solution: Using PA66+30% glass fiber material, optimizing mold cooling system

- Quality indicators: Dimensional accuracy ±0.1mm, high temperature resistance 150°C, impact strength ≥80kJ/m²

Case 2: Medical Device Components

- Project background: Customizing surgical instrument handles for a medical device company

- Technical challenges: Medical-grade materials, high precision, surface antibacterial treatment

- Solution: Using ABS medical-grade material, mold surface coated with antibacterial coating

- Quality indicators: Complies with GB/T 16886 standard, cytotoxicity grade 1

Case 3: Electronic Device Housings

- Project background: Customizing smartphone housings for a consumer electronics enterprise

- Technical challenges: Thin-walled structure, high-gloss surface, drop performance

- Solution: Using PC+ABS alloy material, optimizing injection molding process parameters

- Quality indicators: Wall thickness 0.8mm, surface roughness Ra≤0.05μm, drop test 1.5m without burst.

Service Commitment: Professional, Efficient, and Reliable

1. Technical Support Commitment

- Provide free DFM analysis services

- 7×24 hour technical consultation support

- Professional design optimization suggestions

2. Quality Assurance Commitment

- All products comply with relevant international and national standards

- Provide detailed quality inspection reports

- 1-year quality guarantee period, lifetime technical support

3. Delivery Time Commitment

- Mold design and manufacturing: 15-30 working days

- Sample production: 5-7 working days

- Mass production: Negotiable according to order quantity

4. After-Sales Service Commitment

- Provide product usage and maintenance guidance

- Support product improvement and optimization services

- Establish customer files and provide long-term technical support

Contact Us: Start Your Custom Plastic Component Journey

- Website: www.xmgoldcattle.com

- ISO 9001:2015 Quality Management System Certification

- ISO 13485:2016 Medical Device Quality Management System Certification

- IATF 16949:2016 Automotive Industry Quality Management System Certification

- National High-tech Enterprise Certification

- ISO 20457:2018 Plastics – Tolerances and acceptance conditions for moulded parts

- GB/T 14486-2019 Dimensional tolerances for plastic moulded parts

- GB 4806.7-2016 Food contact plastic materials and articles

- GB/T 16886 Biological evaluation of medical devices

- RoHS 2.0 Restriction of Hazardous Substances Directive