Custom plastic spray bottles are versatile solutions for various needs. For beauty brands, they create fine-mist toner bottles; cleaning companies can design leak-proof disinfectant sprays, and gardeners get gentle plant misting containers. These bottles aren’t just containers—they’re engineered for specific spraying functions, like ultra-fine mists for skincare, steady streams for cleaning, and ergonomic shapes for comfort.

1. Materials: Choosing Plastics That Handle Your Spray’s Contents

The right material for custom plastic spray bottles depends entirely on what you’ll put inside it—chemicals, oils, serums, or water-based solutions. Here are the top picks, tailored to performance:

- HDPE (High-Density Polyethylene): The workhorse for cleaning and industrial sprays. HDPE is resistant to most household chemicals (bleach, ammonia, degreasers) and solvents, so it won’t crack or leach toxins into your formula. It’s opaque (hides colored cleaners) and durable—perfect for heavy-duty use, like garage degreasers or bathroom cleaners.

- PET (Polyethylene Terephthalate): A favorite for beauty and personal care sprays. PET’s crystal clarity lets customers see your product (think clear toner or hair mist), and it’s lightweight enough for on-the-go use (travel-sized perfume sprays). It’s also resistant to water-based formulas and mild oils, plus 100% recyclable—ideal for eco-conscious beauty brands.

- PP (Polypropylene): Great for heat-sensitive or thick formulas. PP handles moderate heat (safe for kitchen sprays stored near stovetops) and works with thicker liquids, like hair styling mists or plant nutrient sprays. It’s flexible (easy to squeeze for manual pumps) and chemical-resistant, making it a versatile choice for both home and professional use.

- LDPE (Low-Density Polyethylene): Perfect for squeeze-to-spray bottles (e.g., kids’ craft paints or gentle plant mists). LDPE is soft and pliable—users can squeeze the bottle to control mist intensity—while still being resistant to water-based solutions. It’s also BPA-free, so it’s safe for products used around children or pets.

Avoid PVC or polystyrene—they’re not chemical-resistant and can break down when exposed to cleaners or oils, ruining your product.

2. Techniques: Crafting Sprays That Work (No Drips, No Clogs)

Custom plastic spray bottles live or die by their spray performance. These techniques ensure every mist, stream, or spritz is consistent and reliable:

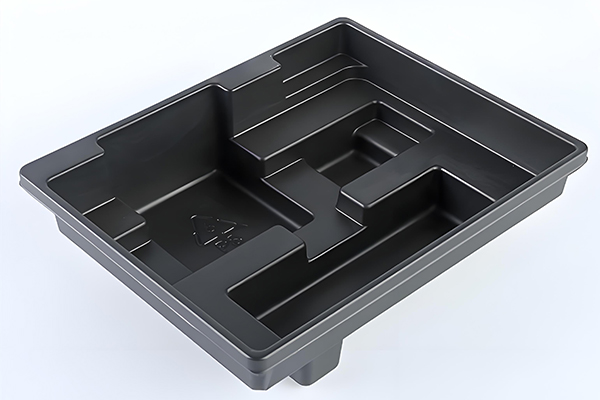

- Blow Molding (for Bottle Bodies): Used to create spray bottle bodies in any shape—slim for purse-friendly beauty and makeup bottles, wide-base for stable cleaning sprays. For HDPE or PP bottles, we use extrusion blow molding (EBM) to make thick, durable walls that hold up to squeezing. For PET bottles (clear beauty sprays), stretch blow molding (SBM) enhances clarity and strength, so the bottle looks premium on shelves.

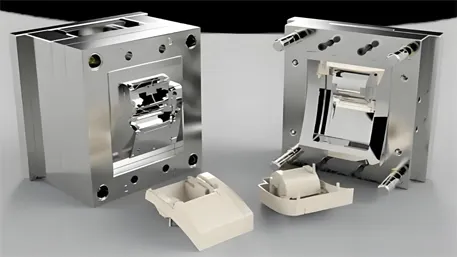

- Injection Molding (for Sprayer Components): The key to leak-free, consistent sprays. We use injection molding to make precision parts:

-

- Nozzles: Tiny, calibrated holes (0.1–0.5mm) that control mist size—smaller holes for fine skincare mists, larger ones for cleaning streams.

-

- Valves & Pumps: Sealed components that prevent leaks and ensure every press delivers the same amount of product. For pressurized sprays (like hairspray), we add airtight gaskets to keep propellants contained.

-

- Trigger Handles: Ergonomic designs that reduce hand fatigue (critical for cleaning bottles used for big jobs).

- Atomization Calibration: A step unique to spray bottles. After assembling, we test each sprayer to adjust mist pattern—whether you need a “cloud” of fine mist (for toners) or a targeted stream (for spot-cleaning). We use laser tools to measure droplet size, ensuring consistency across every bottle in your order.

- Surface Finishing: For both style and function. Matte coating on PET beauty bottles prevents fingerprints; ribbed textures on HDPE cleaning bottles improve grip when hands are wet; and embossed logos (raised designs) add a premium feel without interfering with squeezing.

3. The Custom Plastic Spray Bottle Production Process

Creating a custom spray bottle means aligning the bottle, sprayer, and formula. Here’s how we make sure everything works in harmony:

- Formula & Use Case Check: First, we ask: What’s in your spray? (Chemical cleaner? Skincare serum? Plant mist?) How will users hold it? (One-handed for travel, two-handed for big jobs?) This tells us the right material, sprayer type, and bottle shape—e.g., a thick HDPE bottle for industrial cleaners, a slim PET bottle for pocket-sized perfumes.

- Design & Prototyping: Using 3D modeling, we draft the bottle (shape, size, grip points) and sprayer (nozzle type, trigger design). We then make a physical prototype so you can test: Does the mist feel right? Is the bottle easy to squeeze? Does the sprayer leak when stored upside down? We tweak until every detail works.

- Material & Sprayer Selection: Based on your formula, we pick the plastic (HDPE for chemicals, PET for beauty) and sprayer (manual pump, trigger spray, pressurized). We also test compatibility—we’ll fill the prototype with your actual formula to ensure the plastic doesn’t react or the sprayer doesn’t clog.

- Mold Creation: We craft custom molds for the bottle body (blow molding) and sprayer parts (injection molding). For sprayers, molds are made with ultra-precise tools to ensure nozzle holes and valves are identical across all parts—no “dud” sprayers.

- Hygienic Production: For beauty or food-related sprays (e.g., edible oil sprays), we run production in cleanrooms to avoid contamination. Bottle bodies are washed and dried before assembly, and sprayers are sealed in sterile packaging until use.

- Performance Testing: Every batch goes through 3 tests:

-

- Leak Test: We fill bottles with water, shake them, and store them upside down for 24 hours—no drips allowed.

-

- Spray Consistency Test: We press the sprayer 50 times and measure how much product comes out each time (variation must be under 5%).

-

- Clog Test: For thick formulas (e.g., hair mists), we run the product through the sprayer 100 times to ensure no clogs.

- Finishing & Assembly: We print your logo (food-safe inks for edible sprays, scratch-resistant inks for cleaners), add labels (waterproof for bathroom sprays), and assemble the bottle and sprayer. Finally, we package them—individual boxes for retail, bulk packs for commercial use.

4. Key Features of Standout Custom Plastic Spray Bottles

Great custom spray bottles don’t just look good—they solve problems. These features make them user-loved:

- Consistent Atomization: No “first spray dribble” or “last spray sputter”—every press delivers the same mist or stream. Critical for beauty brands (users hate uneven toner application) and cleaning companies (inconsistent sprays mean missed spots).

- Leak-Proof Seals: A must for travel-sized sprays (no ruined makeup bags!) and cleaning bottles stored under sinks. Our precision valves and gaskets keep liquid inside, even when bottles are tossed in backpacks or tipped over.

- Ergonomic Design: Spray bottles used for 5+ minutes (e.g., cleaning a kitchen) need comfortable triggers. We design handles that fit most hand sizes and reduce pressure—no more sore fingers after a big clean.

- Formula Compatibility: The bottle and sprayer work with your product, not the other way around. For example, we’ll add chemical-resistant gaskets for bleach sprays or anti-clog nozzles for thick hair products.

- Brand Alignment: Custom colors (match your brand palette), finishes (matte, glossy, metallic), and logo placements (front, side, or even on the trigger) turn the bottle into a marketing tool. A sleek PET spray bottle with a gold trigger, for example, feels luxury—perfect for high-end skincare.

5. Equipment: Tools for Reliable Spray Performance

The right equipment ensures every spray bottle works as intended—no shortcuts, no defects:

- Extrusion/Stretch Blow Molding Machines: For bottle bodies. EBM machines make thick-walled HDPE/PP bottles; SBM machines create clear, strong PET bottles. Both have adjustable settings to make bottles of any size (10ml travel sprays to 1L cleaning bottles).

- Precision Injection Molding Machines: For sprayer parts. These machines use computer-controlled systems to make nozzles with exact hole sizes and valves with tight seals. We use stainless steel molds to avoid contamination, critical for beauty or food sprays.

- Atomization Testing Tools: Laser particle analyzers measure droplet size (ensuring fine mists stay fine) and flow meters check how much product is released per press. This equipment catches inconsistencies before bottles leave the factory.

- Leak Testing Machines: We use two methods:

-

- Vacuum Testing: For pressurized sprays—bottles are placed in a vacuum chamber to detect tiny leaks.

-

- Immersion Testing: For manual sprays—bottles are filled with colored water, pressed 100 times, and checked for drips.

- Ergonomic Testing Rig: A device that simulates 1,000+ trigger presses to test handle comfort and durability. We adjust trigger tension until it’s easy to press but not so loose that it leaks.

6. Production: Balancing Performance, Safety, and Speed

Making custom plastic spray bottles means juggling three priorities: the spray works, it’s safe, and it’s ready on time. Here’s how we do it:

- Material Compatibility Testing: Before production, we soak plastic samples in your formula for 72 hours. If the plastic swells, discolors, or leaches chemicals, we switch to a more suitable material—no surprises after production.

- Waste Reduction: We recycle excess plastic from blow/injection molding (e.g., HDPE scraps from cleaning bottles) back into the process. For PET bottles, we offer post-consumer recycled (rPET) options to cut down on plastic waste.

- Batch Consistency: We use automated systems to monitor every step—temperature during blow molding, pressure during injection molding, and spray performance during testing. This ensures the first bottle in a batch is identical to the last.

- Fast Turnaround: For urgent orders (e.g., a cleaning company needing bottles for a new product launch), we offer expedited production (2–3 weeks for small batches). We never skip safety tests—we just optimize our workflow to meet your deadline.

7. Applications: Where Custom Plastic Spray Bottles Shine

Custom spray bottles are versatile—here’s how different industries use them to solve unique problems:

- Beauty & Skincare: Slim PET bottles with fine-mist nozzles for toners, facial mists, or hair serums. Matte finishes and metallic triggers add luxury, while travel-sized (30ml) options fit TSA rules—perfect for on-the-go touch-ups.

- Household Cleaning: Wide-base HDPE bottles with trigger handles for all-purpose cleaners, glass sprays, or degreasers. Waterproof labels and grip textures (to prevent slipping when wet) make them practical for daily use.

- Gardening & Plant Care: Soft LDPE squeeze bottles or PP trigger sprays for plant mists, fertilizers, or pest repellents. Gentle mist nozzles won’t damage delicate leaves, and clear bodies let users see how much product is left.

- Industrial & Professional: Thick PP or HDPE bottles with heavy-duty triggers for industrial cleaners, lubricants, or rust inhibitors. Chemical-resistant gaskets and leak-proof seals ensure safety in workshops or job sites.

- Food & Beverage: BPA-free PET or PP bottles for edible oil sprays, cooking mists, or fruit glazes. Food-safe inks and clear bodies let customers see the product, while precise nozzles control portion sizes.

FAQs: Your Custom Plastic Spray Bottle Questions Answered

Q1: Can custom spray bottles handle thick formulas (like hair styling mists)?

Yes! We’ll use larger nozzle holes (0.3–0.5mm) and adjust the sprayer’s pump pressure to prevent clogs. We also test your formula in the prototype to ensure smooth spraying.

Q2: Are the bottles safe for chemical cleaners (like bleach or ammonia)?

Absolutely—we use HDPE or PP, which are resistant to most household and industrial chemicals. We also add chemical-resistant gaskets to the sprayer to prevent leaks.

Q3: Can I order small batches (e.g., 50 bottles) for a product test?

Yes! We support small-batch orders starting at 50 units. This is great for startups testing a new spray product or brands wanting to sample different designs.

Q4: How do I choose between a trigger spray and a manual pump?

Trigger sprays are better for large jobs (e.g., cleaning a room) — they deliver more product with less effort. Manual pumps (squeeze or press-top) are better for small, precise applications (e.g., facial mists) or travel-sized bottles.

Ready to Design Your Custom Plastic Spray Bottle?

Whether you need a luxury beauty mist bottle or a durable cleaning spray container—we’ll tailor every detail to your formula and users. Leave us a message below with your needs (formula type, size, spray pattern, or deadline), and our team will send you a free design mockup and compatibility test. Let’s create a spray bottle that works as hard as your product does!