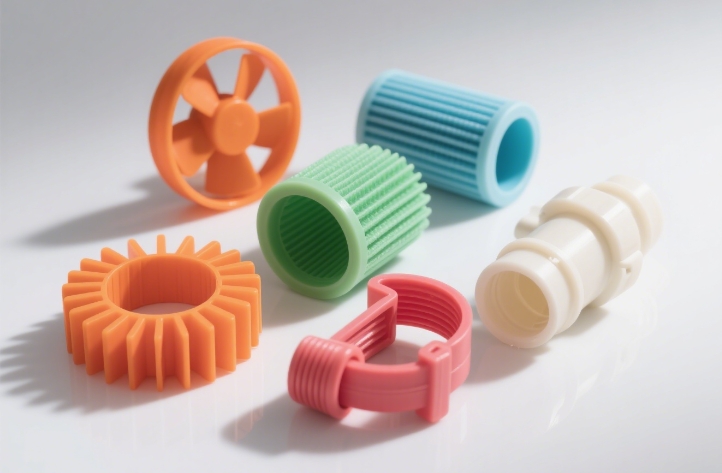

In industries such as packaging, automotive interiors, and home appliances, polypropylene (PP) has become the material of choice for injection molding due to its lightweight nature, strong chemical resistance, and low cost. However, traditional injection molding often faces issues when processing customized PP parts, such as large dimensional deviations (tolerances exceeding ±0.1mm), obvious surface sink marks, and a high warpage deformation rate (exceeding 3%). The customized PP injection – molding service, through optimized mold design, intelligent injection – molding processes, and full – process quality control, can control dimensional tolerances within ±0.05mm and reduce sink – mark depth by 80%, providing enterprises with an efficient and precise customized PP part solution.

I. Why Can’t Traditional Injection Molding Meet the Requirements of Customized PP Parts?

Q&A: What are the core advantages of the customized PP injection – molding service?

Traditional injection molding has three core pain points when dealing with customized PP parts:

Uncontrolled Dimensional Accuracy

The shrinkage rate of PP material is high (1.2% – 2.5%). Traditional mold designs do not accurately compensate for this, resulting in large dimensional deviations of parts. The fitting rate during assembly is less than 70%.

Frequent Surface Defects

Short shots are likely to occur in thin – walled parts (wall thickness ≤ 1.5mm), and sink marks are likely to occur in thick – walled parts (wall thickness ≥ 3mm). Under traditional processes, the surface defect rate is as high as 15% – 20%.

Low Production Efficiency

The injection – molding parameters are not optimized according to the characteristics of PP materials. The molding cycle is as long as 30 – 60 seconds, and the mold life is short (about 50,000 times), resulting in a 40% increase in costs.

The customized PP injection – molding service focuses on “precision, efficiency, and high quality”:

Full – process Precise Control

Dimensional Accuracy Assurance: Using mold – flow analysis (CAE) to accurately calculate the shrinkage rate, combined with high – precision molds (accuracy of ±0.02mm), the dimensional tolerance is controlled within ±0.05mm, and the fitting rate is increased to 98%.

Defect Prevention System: By optimizing the gate layout, runner design, and packing process, the sink – mark depth is reduced from 0.3mm to less than 0.05mm, and defects such as short shots and warping are reduced by 90%.

Data – driven Efficient Production

Using an intelligent injection – molding system to optimize process parameters in real – time, the molding cycle is shortened to 15 – 30 seconds, the mold life is extended to more than 100,000 times, production efficiency is increased by 50%, and costs are reduced by 30%.

II. How to Achieve Breakthroughs in the Core Processes of Customized PP Injection Molding?

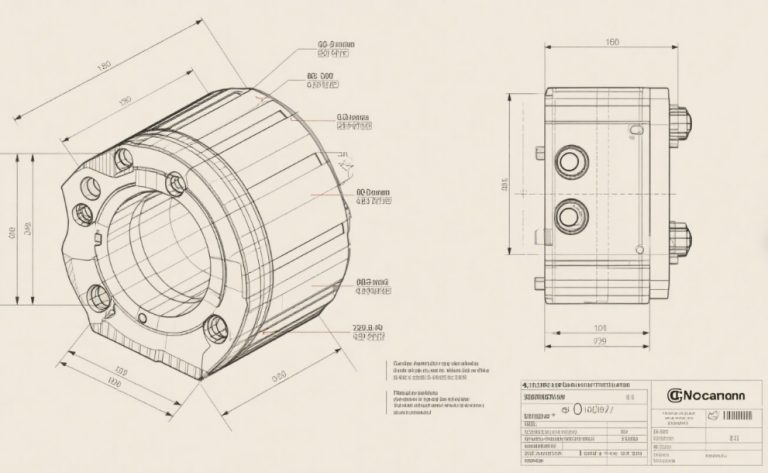

Innovation in Mold Design and Manufacturing

Intelligent Shrinkage Compensation Design: Based on the PP material grade (homopolymer / copolymer) and part wall thickness, use Moldflow to simulate the shrinkage trend. Reserve a compensation amount of 0.5% – 2% in the mold – design stage to ensure accurate molding dimensions.

Conformal Cooling Molds: Use 3D printing technology to manufacture the mold cooling water channels, which are designed to fit the complex surfaces of parts. The temperature uniformity of the mold is increased by 60%, the cooling time is shortened by 40%, and the single – piece molding cycle is reduced from 40 seconds to 24 seconds.

Wear – resistant Mold Materials: Select S136 mold steel (hardness HRC52), and the surface is treated with TD coating (thickness 3 – 5μm). The wear resistance is increased by 3 times, and the mold life is extended to more than 100,000 times, which is suitable for long – term mass – production requirements.

Intelligent Injection – molding Processes

Precise Injection – molding Equipment: Equip servo – hydraulic injection – molding machines (clamping force 500 – 2000T), with an injection – speed control accuracy of ±1mm/s and a pressure control accuracy of ±0.5MPa, to ensure that the PP melt fills the cavity quickly and evenly.

Multi – stage Injection Control: Use pressure sensors (accuracy ±0.5MPa) and displacement sensors (accuracy ±0.05mm) to monitor the melt flow in real – time. Control the injection speed (0.1 – 1m/s) and pressure (80 – 180MPa) in stages to avoid problems such as jetting and short shots, and the filling success rate is over 99%.

Dynamic Mold – temperature Regulation: Use an oil – water – cooled hybrid temperature – control system to accurately control the mold temperature at 40 – 60℃, reducing the internal stress of PP materials caused by temperature differences. The warpage deformation rate is reduced from 3% to less than 0.8%.

Digital Production Control System

Mold – flow Analysis and Pre – research: Use Moldflow software to simulate the flow state of the PP melt in the mold, optimize the number of gates (usually 1 – 3), runner diameter (8 – 15mm), and cooling – circuit layout, and predict and solve more than 85% of molding defects in advance.

Intelligent Process Regulation: Real – time collect more than 60 parameters such as mold temperature, melt pressure, and screw speed. The AI algorithm automatically adjusts the process curve to compensate for material batch differences and environmental temperature changes. The good – product rate is increased from 82% to 95%.

Digital Twin Monitoring: Create a digital – twin model for each set of molds, simulate the production process in real – time, predict mold wear and part – deformation trends, and carry out maintenance and process optimization in advance, reducing unplanned downtime by 40%.

III. Quality Control: Stringent Verification from Mold to Finished Product

Multi – dimensional Performance Testing System

Dimensional Testing: Use a coordinate measuring machine (accuracy ±0.03mm) to detect key dimensions and geometric tolerances (flatness ≤ 0.1mm); for small – diameter holes, use an image – measuring instrument (accuracy ±0.01mm) for high – precision detection.

Appearance Testing: The AI visual – inspection system (resolution 20 million pixels) completes surface inspection in 0.8 seconds, identifying scratches at the 0.1mm level and depressions below 1mm², with a missed – detection rate of less than 0.003%.

Function Testing: Conduct drop tests (free – fall from a height of 1m) on packaging parts, and wear – resistance tests (no wear after 5000 frictions) on automotive interior parts to verify actual performance.

Component Analysis: Use Fourier – transform infrared spectroscopy (FT – IR) to detect the purity of PP materials, ensure that the content of additives (such as antioxidants and flame retardants) meets the GB/T 12670 standard, and the impurity content is less than 0.1%.

Physical Property Testing: Measure indicators such as melt flow index (2 – 40g/10min), heat – deflection temperature (HDT 50 – 120℃), and tensile strength (≥20MPa), and control the error from the standard value within ±3%.

Raw – material Testing

Finished – product Testing

Intelligent Defect – prevention Technology

First – piece Twelve – inspection System: The engineering team strictly inspects 40 indicators of the first – piece product, such as mold status, material batch, and process parameters, to intercept potential defects.

Real – time Process Monitoring: Through pressure sensors and temperature sensors embedded in the mold, the melt – filling and cooling processes are monitored in real – time. In case of abnormal conditions, an alarm is automatically triggered and the machine stops to prevent batch – quality problems.

IV. How Does Customized PP Injection Molding Balance Efficiency and Cost?

Q&A: Does customized production mean high costs and low efficiency?

Through three innovative models, customized PP injection molding achieves a 30% – 40% cost reduction and a 50% efficiency increase:

Mold Optimization Strategy

Adopt modular mold design and quick – mold – change technology (mold – change time < 15 minutes), reducing mold – development costs by 35% while meeting the needs of multi – variety and small – batch production.

Energy – management System

Intelligently regulate the servo – motor power of the injection – molding machine and the cooling – water temperature of the mold. Combine with waste – heat recovery technology to reduce energy consumption by 25% and the single – piece production cost by 18%.

Shared Manufacturing Platform

Integrate the customized order requirements of multiple customers, schedule production centrally, and share injection – molding equipment resources. The equipment utilization rate is increased from 50% to 80%, further reducing costs.

V. Core Considerations for Choosing Customized PP Injection – molding Services

Equipment and Technical Strength

The supplier should have high – precision injection – molding machines, mold – flow analysis software, and core technologies such as conformal cooling molds and multi – stage injection.

Industry Certification Qualifications

Possess certifications such as ISO 9001, ISO 14001, and food – grade material certifications (such as FDA) to ensure that products meet industry standards.

Digital Capabilities

Have mold – flow analysis, intelligent production – management systems, and digital – twin technologies to achieve full – process data – driven production and ensure efficient and controllable production.

Conclusion

The customized PP injection – molding service, driven by innovative technologies and intelligent management, overcomes the technical bottlenecks of traditional injection molding, providing efficient and precise customized part solutions for industries such as packaging, automotive, and home appliances. In the trend of the manufacturing industry towards intelligence and personalization, customized services with “advanced mold technology + intelligent molding process + full – chain quality control” are becoming the key support for enterprises to enhance their competitiveness and achieve innovative development. From food – packaging containers to automotive interior components, the customized PP injection – molding service will continue to assist enterprises in achieving efficient production and innovative development with excellent precision and efficiency.

(Contact us immediately to obtain a customized PP injection – molding solution and a free mold – flow analysis service)