Our PP Plastic Manufacturing Expertise

1. High-Efficiency PP Injection Molding

- Excels in thin-wall PP molding (down to 0.6mm) for lightweight packaging, automotive components, and consumer goods

- Supports copolymer PP (impact-resistant) and homopolymer PP (high stiffness) molding, with consistent dimensional stability

- Enables high-speed production (up to 1,500,000 pieces/month) for cost-sensitive, large-quantity orders

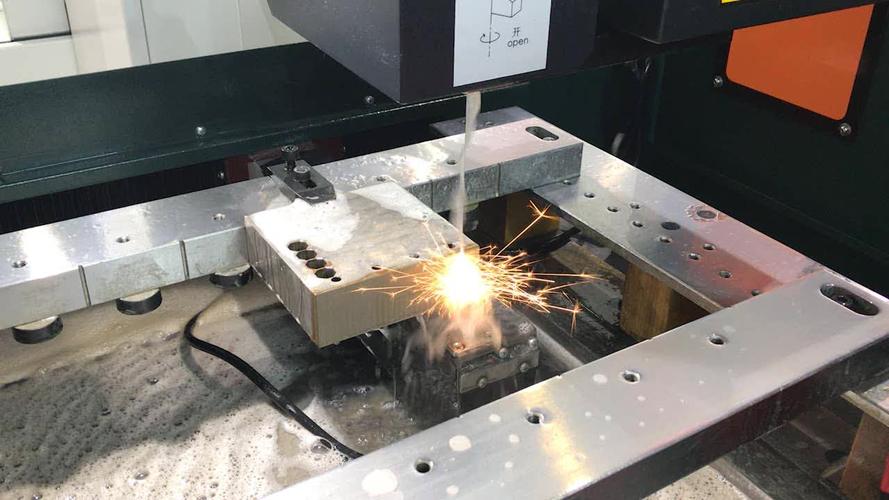

2. Precision PP CNC Machining

- 5-axis machining capability with ±0.005mm tolerance for PP parts like living hinges, custom fittings, and mechanical components

- Expertise in machining filled PP grades (e.g., talc-filled PP for enhanced rigidity, glass fiber-filled PP for structural strength)

- Minimizes material waste with optimized tool paths, ensuring cost-effectiveness for small-batch PP projects

3. PP-Specific Secondary & Finishing Services

- Overmolding: Combine PP with TPE/TPR for soft-grip surfaces (e.g., tool handles, consumer device casings)

- Surface Treatment: Corona treatment (to improve adhesion for printing/painting), flame treatment, and anti-static coating

- Assembly: Integration of PP parts with hardware (threaded inserts, snap fits) and ultrasonic welding for seamless joints

- Packaging Compatibility: Food-grade PP finishing (compliant with FDA/EFSA standards) for packaging and kitchenware

Table 1: Custom PP Manufacturing Capabilities at a Glance

|

Capability

|

Key Process

|

Best For

|

Tolerance Range

|

|

High-Volume Production

|

PP Injection Molding

|

Lightweight, cost-sensitive PP parts (packaging, automotive interiors, household items) in large quantities

|

+/- 0.05 – 0.15mm

|

|

Prototyping & Low-Volume

|

PP CNC Machining

|

PP prototypes, complex geometries, tight-tolerance components (e.g., living hinges)

|

+/- 0.001 – 0.01mm

|

|

Enhanced Rigidity

|

Filled PP Molding (Talc/Glass Fiber)

|

Structural PP parts (automotive brackets, industrial fittings) requiring higher stiffness

|

+/- 0.06 – 0.12mm

|

|

Value-Added Finishing

|

Overmolding, Corona Treatment, Assembly

|

Improving PP’s adhesion, functionality, and readiness for end-use

|

N/A

|

PP Material Expertise: Tailored to Your Needs

Table 2: Custom PP Material Selection Guide

|

PP Grade

|

Key Properties

|

Typical Custom Applications

|

|

Homopolymer PP (HPP)

|

High stiffness, good heat resistance, low cost

|

Food containers, industrial fittings, automotive trim

|

|

Copolymer PP (CPP)

|

Excellent impact resistance (even at low temperatures), flexibility

|

Living hinges, automotive bumpers, consumer device casings

|

|

Talc-Filled PP (20-40%)

|

Enhanced rigidity, dimensional stability, reduced shrinkage

|

Automotive dashboards, appliance housings, structural brackets

|

|

Glass Fiber-Filled PP (10-30%)

|

High strength, load-bearing capacity, heat resistance

|

Industrial machinery components, under-hood automotive parts

|

|

Food-Grade PP

|

Non-toxic, chemical-resistant, compliant with FDA/EFSA standards

|

Food packaging, kitchenware, beverage containers

|

|

Flame-Retardant PP

|

UL94 V0 rating, fire resistance, retained mechanical properties

|

Electronic enclosures, electrical components

|

Industries We Serve with Custom PP Parts

Automotive & Transportation

Packaging & Food Industry

Home Appliance & Hardware

Industrial & Manufacturing

Consumer Electronics

The Goldcattle Advantage for Custom PP Parts

PP-Specific Engineering Support

Rigorous Quality Control

Efficient Global Delivery

Our Custom PP Part Process Flow

- Consultation & DFM: Discuss your requirements, select PP grade, and optimize design for manufacturability (addressing PP’s shrinkage and surface properties)

- Quotation & Tooling Design: Custom mold design for injection molding or CNC programming for machining

- Prototype & Approval: Produce sample PP parts for testing and validation (including food safety or chemical resistance checks if needed)

- Mass Production & QC: Scale production with continuous quality checks, ensuring consistency for high-volume orders

- Delivery & After-Sales Support: Timely shipping and ongoing technical assistance for PP part performance optimization

Let’s Create Your Custom PP Plastic Parts

Company Information

- Year Established: 2014

- Plant Area: 5,000-10,000 square meters

- Key Certifications: ISO 9001:2000

- PP Production Capacity: 1,500,000 pieces per month

- Export Markets: North America, Northern Europe, and beyond

- Website: https://www.xmgoldcattle.com/

- Location: Xiamen, Fujian, China

- Port: FOB Xiamen