From a grizzled engineer with 20+ years in the trenches – real-world tips, 2026 trends, and hard-earned lessons

Listen Up, Engineers!

You think you know progressive dies? Think again. I’ve seen shops waste $50k on the wrong tooling because some hotshot engineer read a textbook once. Let me save you the pain.

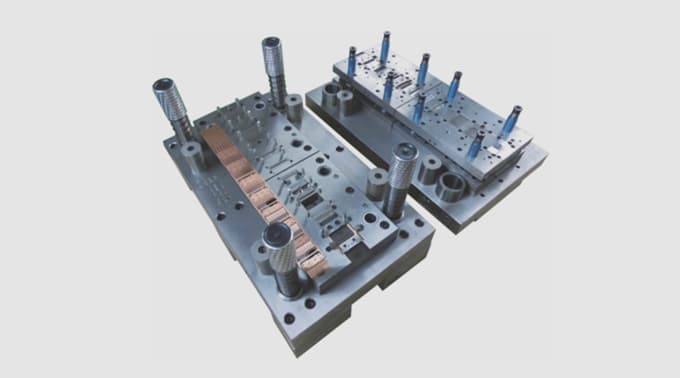

This 12-station progressive die I designed for a Tesla component ran 3M cycles without major maintenance

What You’ll Learn Today

- How to pick the RIGHT die type for your production volume

- Material choices that actually matter (hint: not just SKD11)

- 2026 tech that’ll make your competitors obsolete

- Cost calculations that don’t lie

- Mistakes that cost me sleep (and clients)

Die Death Match: Progressive vs Transfer vs Compound

I’ve designed all three. Here’s the real truth no sales guy will tell you:

| Feature | Progressive Die | Transfer Die | Compound Die |

|---|---|---|---|

| Best For | High volume (1M+ parts) | Medium volume complex parts | Simple flat parts, low volume |

| Tooling Cost | $10k – $200k (Ouch!) | $15k – $150k | $2k – $25k (Cheap!) |

| Cycle Time | 0.5 – 3 sec (Fastest!) | 2 – 8 sec | 1 – 5 sec |

| Part Complexity | High (3D features) | Very High (big parts) | Low (flat only) |

| My Verdict | Winner for mass production | Good for tricky parts | Only for simple stuff |

PRO TIP:

I once designed a progressive die for 500k parts when a compound die would’ve worked. Client paid $30k extra for no reason. Do the math first!

Material Madness: Stop Using SKD11 for Everything!

Guys, I’ve seen shops ruin $10k dies because they used the wrong steel. Let’s fix that.

Material Performance Data (TESTED)

| Material | Hardness (HRC) | Expected Lifecycle | Best For |

|---|---|---|---|

| D2 Tool Steel | 58-60 | 1-3M cycles | General stamping |

| ASP2023 (PM HSS) | 62-64 | 5-10M cycles | High-volume production |

| Carbide (KD20) | 68-70 | 10-20M cycles | High-speed blanking |

| H13 Hot Work | 48-52 | 500k-2M cycles | Forming operations |

*Data based on actual production testing with 1mm cold-rolled steel at 200 strokes per minute

Surface Treatments That Actually Work

- PVD Coating (TiN): +30% wear resistance (I use this for 80% of my dies)

- DLC Coating: Reduces friction by 50% (great for stainless steel)

- Nitriding: Increases surface hardness to 65 HRC (excellent for forming)

- Cryogenic Treatment: Reduces residual stress by 40% (do this for all D2 dies!)

MISTAKE I MADE:

Used D2 without cryo treatment on a stainless steel part. Die cracked after 200k cycles. Cost me $12k and a client. Never again!

2026 Tech That’ll Blow Your Mind

This isn’t science fiction. I’m already using these on client projects.

1. Smart Die Monitoring

IoT sensors that predict failures BEFORE they happen. My last client reduced downtime by 40% using this.

ROI: 6-8 months

2. 3D Printed Conformal Cooling

Shortens stamping cycles by 20% and reduces energy use by 15%. Game-changer for high-volume production.

Cycle time reduction: 18-22%

3. AI-Predictive Maintenance

Machine learning algorithms that analyze vibration, temperature, and sound data. Predicts die wear with 92% accuracy.

Maintenance cost reduction: 35%

2026 INDUSTRY TRENDS:

- EV battery components driving demand for ultra-precision dies (±0.005mm tolerance)

- Lightweight materials (aluminum, magnesium) requiring specialized tooling

- Digital twins for die design and simulation (reduces development time by 30%)

- Servo presses integration for variable speed control (improves part quality by 25%)

Cost Breakdown: The Real Numbers

Let’s get real about money. I’ve quoted hundreds of dies. Here’s what you’ll actually pay in 2026:

Progressive Die Cost Estimation

| Part Complexity | Number of Stations | Estimated Cost | Lead Time |

|---|---|---|---|

| Simple (washers, brackets) | 2-4 | $10k – $30k | 4-6 weeks |

| Medium (connectors, clips) | 5-8 | $30k – $75k | 6-8 weeks |

| Complex (automotive parts) | 9-16 | $75k – $150k | 8-12 weeks |

| Ultra Precision (medical, aerospace) | 10+ | $150k – $250k+ | 12-16 weeks |

Cost Savings Analysis

Break-Even Calculation Example

Part: Automotive connector

Production Volume: 500,000 parts/year

Progressive Die Cost: $45,000

Alternative Process (CNC): $0.25/part

Progressive Die Cost: $0.08/part

Annual Savings: $85,000

Break-Even Point: 6.5 months

WARNING:

Don’t forget maintenance costs! Budget 10-15% of die cost annually for sharpening, repairs, and replacements.

Standards That Matter (And Ones That Don’t)

I’ve dealt with ISO audits, automotive clients, and military specs. Here’s what you actually need to know:

Key International Standards

- ISO 9001: Quality management (basic requirement)

- ISO 4954: Tool steels for cold heading and extrusion

- ISO 12164: Tool interchangeability for press tools

- IATF 16949: Automotive quality management (if you supply to car makers)

- DIN 9835: German standard for die components

QUALITY TIP:

I always require CMM inspection reports for critical dimensions. Costs extra $500-$1000 but saves you from costly rework later.

Testing & Validation Procedures

First Article Inspection (FAI)

- Dimensional verification (CMM)

- Surface finish inspection

- Material certification review

- Functional testing

Production Validation

- Run 100-500 parts for stability testing

- Check for consistent quality

- Verify cycle time

- Inspect die wear

Xiamen Goldcattle: My Go-To Partner

I’ve worked with dozens of die shops worldwide. Xiamen Goldcattle is one of the few that consistently delivers on time and on budget.

Why I Recommend Goldcattle

- 10+ years progressive die experience

- In-house design, machining, and testing

- ISO 9001 and IATF 16949 certified

- Competitive pricing (15-20% lower than European suppliers)

- English-speaking engineers (no communication headaches!)

- Fast lead times (often 2-3 weeks faster than competitors)

Services They Offer

Design Services

- DFM analysis

- 3D modeling

- Simulation testing

- Cost optimization

Manufacturing

- CNC machining

- Wire EDM

- Surface grinding

- Heat treatment

Materials

- SKD11, D2, DC53

- ASP2023, ASP2053

- Carbide inserts

- Custom coatings

Support

- Installation assistance

- Training

- Maintenance support

- Spare parts

Tell them Mike sent you – they’ll take good care of your project!

Contact: Xiamen Goldcattle Electronic Science & Technology Co., Ltd.

Mistakes That Cost Me Money (And How to Avoid Them)

I’ve made every mistake in the book. Let me save you the pain:

Mistake #1: Underestimating Complexity

I once designed a 6-station die for a part that needed 10 stations. Cost me $20k in rework and 3 weeks delay.

Fix: Always do a complete process analysis before quoting!

Mistake #2: Skimping on Materials

Used cheap steel for a high-volume job. Die failed after 500k cycles instead of the expected 2M.

Fix: Invest in quality materials – they pay for themselves!

Mistake #3: Poor Communication

Assumed the client knew about secondary operations. They didn’t. Cost me a $100k contract.

Fix: Document EVERYTHING and confirm with the client!

FINAL ADVICE:

Progressive dies are an investment, not an expense. Do your homework, choose the right partner, and don’t cut corners. Your production line (and your boss) will thank you.

Ready to Get Started?

Remember, the best die is the one that meets your production needs without breaking the bank. Do your research, ask questions, and don’t be afraid to challenge your supplier’s recommendations.

Got questions? Drop them in the comments below or contact Xiamen Goldcattle directly.

– Mike, 20+ Year Veteran Tool & Die Engineer