Core Manufacturing Technologies: Engineering for Thermal & Pressure Resistance

1. Advanced Material Formulation

- EPDM rubber compounding: Blends EPDM with carbon black and plasticizers to achieve -40℃ to 135℃ temperature resistance, 300kPa burst pressure, and 50% elongation at break. A truck radiator hose with 6mm wall thickness maintained flexibility at -40℃ and showed no cracking after 1,000 thermal cycles, exceeding SAE J20R4 standards.

- Silicone rubber engineering: Formulates high-temperature silicone (VMQ) with ceramic fillers for 150-180℃ continuous operation, ideal for racing and turbocharged engines. A performance car radiator hose with 4-ply reinforcement withstood 180℃ coolant temperature (30℃ higher than EPDM) without hardening, maintaining 250kPa pressure stability.

- Textile reinforcement integration: Embeds polyester or aramid fibers (Kevlar) in hose walls, increasing burst pressure by 80% vs. unreinforced hoses. A 50mm diameter industrial radiator hose with 4-ply polyester reinforcement achieved 600kPa burst pressure, suitable for heavy machinery cooling systems.

2. Precision Extrusion & Molding

- Continuous extrusion: Produces straight hoses (10-150mm ID) with ±0.5mm diameter tolerance and uniform wall thickness (±0.3mm), ensuring consistent flow rates (±5% variation). A 25mm ID automotive radiator hose maintained 90L/min flow across 10,000 units, minimizing pressure drop in cooling circuits.

- Mandrel molding for complex shapes: Creates curved, branched, or multi-port hoses (e.g., Y-shaped heater hoses) with precise bend radii (≥3× ID) and ±1mm dimensional accuracy. A tractor radiator hose with 3 bends (90°/45°/120°) maintained 0.1mm wall thickness uniformity, preventing kinking during installation.

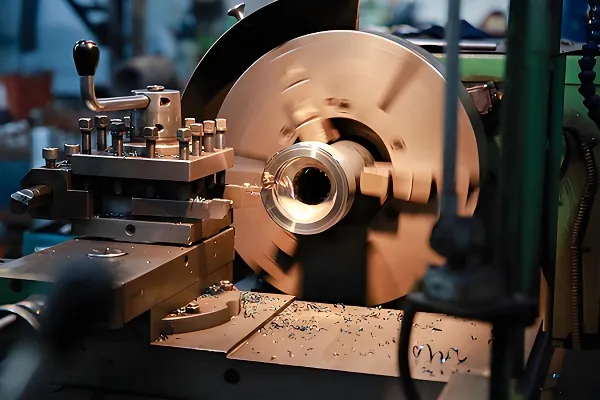

- Crimping technology: Uses CNC-controlled crimping machines to attach metal fittings (aluminum/steel) with 0.05mm precision, ensuring leak-proof seals (≤0.1cc/min leakage at 300kPa). A construction machinery radiator hose with crimped ends passed 5,000 pressure cycles without loosening.

3. Surface Treatment & Protection

- Abrasion-resistant coating: Applies polyurethane outer layers (0.2mm thickness) to prevent hose wear from contact with engine components, extending service life by 30% in tight engine bays. A compact car radiator hose with this coating showed minimal wear after 100,000km road testing.

- UV stabilization: Adds UV inhibitors to EPDM/silicone compounds, preventing surface cracking and color fading (ΔE <3 after 3,000 hours UV exposure). A agricultural machinery radiator hose with UV protection maintained flexibility in direct sunlight, unlike standard hoses that hardened after 12 months.

- Fluid compatibility treatment: Treats inner surfaces with anti-aging additives, ensuring resistance to ethylene glycol, propylene glycol, and water-glycol mixtures (no swelling after 1,000 hours immersion).

4. Performance Testing & Validation

- Pressure cycling: Tests hoses through 100,000 cycles (0-300kPa) at 120℃, ensuring no leaks or reinforcement separation. A heavy-duty truck radiator hose maintained 250kPa pressure stability, withstanding the equivalent of 500,000km of engine operation.

- Thermal shock testing: Subjects hoses to rapid temperature changes (-40℃ to 135℃ in 5 minutes) for 500 cycles, verifying flexibility and seal integrity. A silicone radiator hose for racing cars showed no cracks or fitting loosening after 500 thermal shocks, exceeding FIA standards.

- Ozone resistance: Exposes hoses to 50pphm ozone at 40℃ for 100 hours (ASTM D1149), ensuring no surface cracking—a critical test for hoses in urban or industrial environments with high ozone levels.

Material Expertise: Matching Materials to Radiator Hose Requirements

|

Material

|

Key Properties

|

Application

|

Advantages

|

|

EPDM Rubber

|

-40℃ to 135℃, 300kPa burst pressure, ELR coolant resistance

|

Automotive, light trucks, standard machinery

|

Cost-effective; balances flexibility and durability; meets SAE J20R4.

|

|

Silicone (VMQ)

|

-60℃ to 180℃, 400kPa burst pressure, high flexibility

|

Racing, turbocharged engines, high-heat industrial

|

Withstands 30% higher temperatures than EPDM; resistant to oil contamination.

|

|

EPDM + Aramid Reinforcement

|

-40℃ to 150℃, 600kPa burst pressure

|

Heavy machinery, off-road vehicles

|

2x stronger than standard EPDM; ideal for high-vibration environments.

|

|

Neoprene (CR)

|

-40℃ to 120℃, oil resistance

|

Marine engines, hydraulic cooling systems

|

Resists petroleum-based fluids; suitable for saltwater environments.

|

Custom Radiator Hose Manufacturing Process

- Design & DFM Validation: Engineers optimize hose designs for:

-

- Bend radii (≥3× ID to prevent kinking)

-

- Wall thickness (4-8mm, based on pressure rating)

-

- Fitting compatibility (barb, flange, or quick-connect designs with ±0.1mm tolerance)

- Material preparation:

-

- Compounding rubber (EPDM/silicone) with additives for temperature/pressure resistance

-

- Preparing reinforcement layers (polyester/aramid fabric, steel wire helix for large diameters)

- Extrusion & molding:

-

- Continuous extrusion for straight hoses (10-150mm ID)

-

- Mandrel molding for complex shapes (bends, branches, reducers)

-

- Vulcanization (160℃ for 10 minutes) to cross-link rubber molecules

- Assembly & finishing:

-

- Crimping metal/plastic fittings (stainless steel, aluminum) with CNC precision

-

- Trimming to length (±1mm tolerance)

-

- Leak testing (100% pressure testing at 150% of rated pressure)

- Quality validation:

-

- Dimensional inspection (ID, OD, wall thickness)

-

- Thermal cycling and pressure testing

-

- Fluid compatibility testing (immersion in coolant for 1,000 hours)

Custom Radiator Hose Application Fields

- Automotive: EPDM radiator hoses for passenger cars (10-50mm ID), silicone hoses for performance vehicles (180℃ rating), and heater core hoses with integrated check valves.

- Heavy Machinery: Aramid-reinforced EPDM hoses for excavators and bulldozers (30-100mm ID), withstanding 250kPa pressure and -40℃ cold starts.

- Industrial Cooling: Large-diameter silicone hoses (80-150mm ID) for generator sets and industrial chillers, resistant to thermal cycling between ambient and 160℃.

- Marine & Off-Road: Neoprene hoses for boats (resistant to saltwater) and off-road vehicles (with steel wire helix to prevent collapse under vacuum).

Customization Capabilities: From Prototype to Production

- Design customization:

-

- Shape complexity (Y-branches, 90° bends, reducers from 20mm to 50mm ID)

-

- Length variation (300mm-3m, with custom cutting to ±1mm)

-

- Reinforcement options (2-6 ply fabric, steel wire helix for suction applications)

- Performance tuning:

-

- Temperature ratings (-40℃ to 180℃)

-

- Pressure ratings (150-600kPa)

-

- Fluid compatibility (ethylene glycol, propylene glycol, water)

- Fitting integration:

-

- Barb fittings (aluminum, brass, stainless steel)

-

- Quick-connect couplings (OEM-compatible with Ford, GM, Cummins)

-

- Flange connections (for industrial machinery)

- Production scalability: 100-5,000 units for prototypes/small batches, 10,000-50,000+ units/year for mass production, with consistent quality across runs.

Common Customization Questions

- Q: What’s the lead time for 1,000 custom Y-shaped radiator hoses?

- Q: How to prevent hose collapse in vacuum applications (e.g., turbocharger cooling)?

- Q: Can hoses be color-coded for fleet maintenance?

- Q: What’s the service life of custom radiator hoses?

-

- EPDM hoses: 5-7 years/150,000km in automotive applications

-

- Silicone hoses: 3-5 years/100,000km in high-temperature environments