Our Resin Plastic Manufacturing Expertise

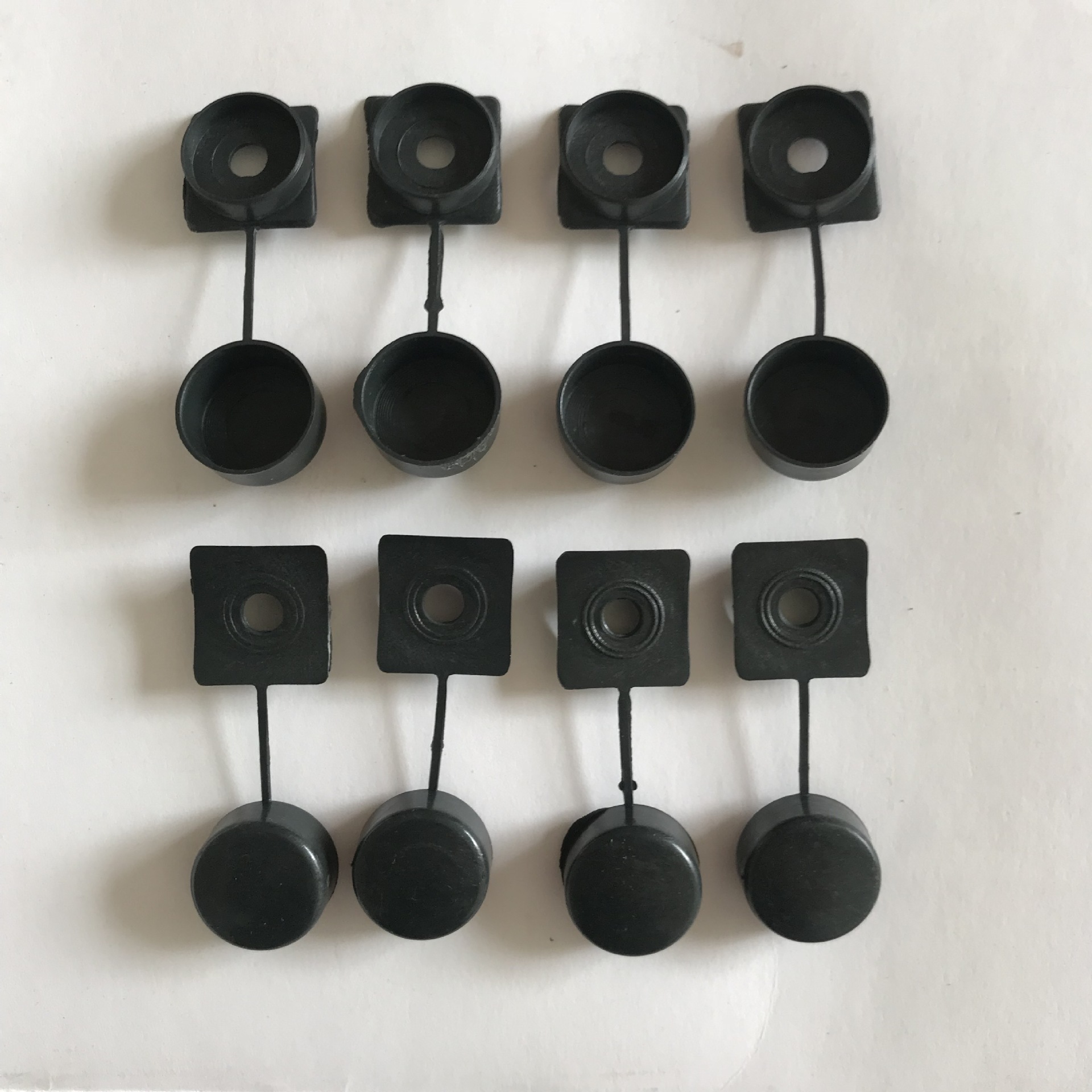

1. Resin Injection Molding & Compression Molding

- Injection Molding: Ideal for thermoset and thermoplastic resins (e.g., epoxy, modified phenolic), supporting complex geometries with tight tolerances for industrial components, electronic enclosures, and automotive parts

- Compression Molding: Specialized for high-strength thermoset resins (e.g., SMC/BMC, phenolic resin), enabling thick-wall parts, high fiber loading, and excellent dimensional stability for structural and heat-resistant applications

- Key advantages: Handles resin-specific curing requirements, minimizes shrinkage, and ensures uniform material distribution for consistent performance

2. Precision Resin CNC Machining & Prototyping

- 5-axis machining capability with ±0.005mm tolerance for resin parts like insulators, precision gears, and aerospace components

- Expertise in machining rigid (epoxy, phenolic) and flexible (silicone resin) resin grades, with specialized tooling to prevent material chipping or cracking

- Ideal for custom resin components with intricate features, critical dimensional accuracy, or functional testing requirements

3. Resin-Specific Secondary & Finishing Services

- Surface Treatment: Polishing (for epoxy resin), coating (anti-corrosion, UV-resistant), and dielectric testing (for insulating resin parts)

- Bonding & Assembly: Adhesive bonding of resin parts with metals/plastics, insert molding (for threaded hardware), and precision assembly

- Curing Optimization: Post-curing processes to maximize resin’s mechanical strength, heat resistance, and chemical stability

- Compliance Finishing: Flame-retardant treatment, FDA-compliant finishing (for food-contact resin parts), and aerospace-grade surface preparation

Table 1: Custom Resin Manufacturing Capabilities at a Glance

|

Capability

|

Key Process

|

Best For

|

Tolerance Range

|

|

High-Volume Production

|

Resin Injection/Compression Molding

|

Structural resin parts, industrial components, electronic enclosures in large quantities

|

+/- 0.05 – 0.12mm

|

|

Prototyping & Precision

|

Resin CNC Machining

|

Low-volume batches, complex resin geometries, tight-tolerance components (insulators, gears)

|

+/- 0.001 – 0.01mm

|

|

High-Strength/Heat-Resistant

|

Thermoset Resin Molding (SMC/BMC)

|

Aerospace parts, automotive under-hood components, industrial machinery parts

|

+/- 0.06 – 0.15mm

|

|

Value-Added Finishing

|

Polishing, Coating, Bonding

|

Enhancing resin’s durability, insulation, and readiness for end-use

|

N/A

|

Resin Material Expertise: Tailored to Your Needs

Table 2: Custom Resin Material Selection Guide

|

Resin Type

|

Key Properties

|

Typical Custom Applications

|

|

Epoxy Resin

|

High strength, excellent adhesion, chemical resistance, electrical insulation

|

Electronic components, aerospace parts, structural brackets

|

|

Polyurethane (PU) Resin

|

Flexibility (from soft to rigid), wear resistance, impact absorption

|

Gaskets, seals, custom foam components, automotive bushings

|

|

Phenolic Resin

|

Exceptional heat resistance (up to 200°C), flame retardancy, low cost

|

Electrical insulators, brake pads, industrial handles

|

|

Unsaturated Polyester Resin

|

High stiffness, corrosion resistance, cost-effective

|

Boat hulls, fiberglass components, construction parts

|

|

Silicone Resin

|

Extreme temperature resistance (-50°C to 250°C), flexibility, biocompatibility

|

Medical devices, automotive gaskets, high-temperature seals

|

|

BMC/SMC Resin

|

High structural strength, dimensional stability, impact resistance

|

Automotive body panels, electrical enclosures, heavy-duty parts

|

Industries We Serve with Custom Resin Parts

Aerospace & Defense

Automotive & Transportation

Electronics & Electrical

Medical & Healthcare

Industrial & Manufacturing

The Goldcattle Advantage for Custom Resin Parts

Resin-Specific Engineering Support

Rigorous Quality Control

Efficient Global Delivery

Our Custom Resin Part Process Flow

- Consultation & DFM: Discuss your requirements, select resin type, and optimize design for manufacturability (addressing resin curing and shrinkage properties)

- Quotation & Tooling Design: Custom mold/tool design for molding or CNC programming for machining, tailored to resin characteristics

- Prototype & Approval: Produce sample resin parts for testing and validation (including heat/chemical resistance checks if needed)

- Mass Production & QC: Scale production with continuous quality checks, ensuring consistent curing and performance for resin parts

- Delivery & After-Sales Support: Timely shipping and ongoing technical assistance for resin part performance optimization

Let’s Create Your Custom Resin Plastic Parts

Company Information

- Year Established: 2014

- Plant Area: 5,000-10,000 square meters

- Key Certifications: ISO 9001:2000

- Resin Production Capacity: 800,000 pieces per month

- Export Markets: North America, Northern Europe, and beyond

- Website: https://www.xmgoldcattle.com/

- Location: Xiamen, Fujian, China

- Port: FOB Xiamen