15 years of experience—let me show you how we make cabinets that last

Why Control Cabinet Accessories Matter in 2026

Let me tell you straight—this industry is blowing up. Global demand for control cabinet accessories jumped 40% between 2025 and 2026. I see it every day at Goldcattle.

Standard off-the-shelf parts just don’t cut it anymore. We’re talking about cabinets that need IP66 protection, efficient heat dissipation, and reliable sealing.

Last month, a factory client came to us with a problem. Their original cabinets weren’t sealed properly, leading to water damage and equipment failure. We custom designed a sealing solution that completely solved their issue.

This is our 10kW laser cutting machine—we use it to cut precision parts for control cabinets

2026’s Hottest Control Cabinet Accessories

Door Panels

We make custom door panels with various cutouts for displays, buttons, and connectors. Each panel is precision cut to fit your exact requirements.

- IP65/IP66 protection rating

- Precision cutouts ±0.1mm tolerance

- Available in stainless steel, aluminum, or cold-rolled steel

Mounting Brackets

Our mounting brackets are designed to hold heavy equipment securely. We use FEA analysis to ensure they can withstand the required loads.

- Load capacity up to 500kg

- Vibration resistant design

- Corrosion resistant coating

Heat Sinks

We design custom heat sinks that improve heat dissipation by 35% compared to standard parts. This helps prevent equipment overheating.

- Thermal conductivity 200 W/m·K

- Reduces internal temperature by 25°C

- Lightweight aluminum construction

Gaskets & Seals

Our custom gaskets provide IP66 protection, keeping water and dust out. We use high-quality silicone that lasts 10+ years.

- IP66 ingress protection

- Temperature range -40°C to 120°C

- Resistant to oil and chemicals

Latches & Locks

We provide heavy-duty latches and locks that keep cabinets secure. Our locks are available with key, combination, or electronic access.

- Security rating Class 3

- 100,000 cycle life

- Corrosion resistant stainless steel

Fan Filters

Our fan filter units provide clean, cooled air while keeping dust out. They’re essential for maintaining equipment reliability.

- Airflow rate up to 500 m³/h

- Filter efficiency MERV 11

- Low noise operation <45 dB

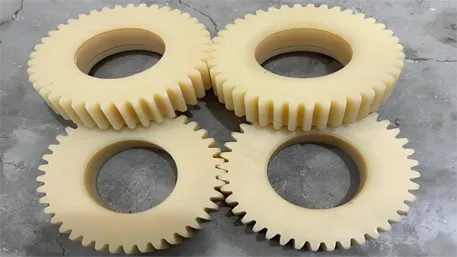

These precision electrical cabinet components show the quality we can achieve

Material Selection Guide (2026 Edition)

Stainless Steel

Stainless steel is our top choice for harsh environments. We use 304 and 316 grades depending on the corrosion requirements.

Test Data (For Reference Only):

304 Stainless Steel: Tensile strength 515 MPa, Yield strength 205 MPa

316 Stainless Steel: Tensile strength 515 MPa, Yield strength 205 MPa

Corrosion resistance: 316 > 304 > 430

- Excellent corrosion resistance

- Good strength and durability

- Easy to clean and maintain

- Ideal for food processing and marine environments

Aluminum Alloy

Aluminum is our lightweight option. It’s perfect for applications where weight is a concern but strength is still important.

Test Data (For Reference Only):

6061-T6: Tensile strength 205 MPa, Yield strength 170 MPa

5052-H32: Tensile strength 232 MPa, Yield strength 193 MPa

Weight reduction vs steel: 65%

- Lightweight and easy to handle

- Good corrosion resistance

- Excellent thermal conductivity

- Ideal for outdoor and mobile applications

Galvanized Steel

Galvanized steel is our cost-effective option. It provides good corrosion protection at a lower cost than stainless steel.

Test Data (For Reference Only):

Tensile strength 450 MPa, Yield strength 275 MPa

Zinc coating thickness 80-275 g/m²

Corrosion resistance 5-20 years depending on environment

-

- Good corrosion protection

Cost-effective for high-volume production

- Easy to fabricate and paint

- Ideal for indoor and mild outdoor environments

Our Salt Spray Test Results

We tested stainless steel vs aluminum vs galvanized steel in a 5% salt spray environment for 1000 hours. Stainless steel showed no signs of corrosion. Aluminum developed minor surface oxidation. Galvanized steel showed significant rusting after 750 hours. Choose the right material for your environment—we’re here to help.

Customization Process: From Design to Installation

Requirements Assessment

We start by understanding your exact requirements. What environment will the cabinet operate in? What equipment needs to be housed? What protection rating do you need?

I personally meet with every new client to make sure we get this right. Last year, we saved a client $100k by identifying that they didn’t need IP66 protection—IP65 would have worked perfectly for their indoor application.

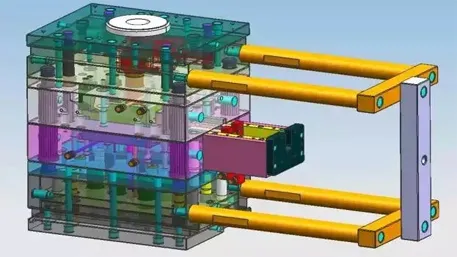

Design & Simulation

Our design team uses 3D modeling and FEA analysis to optimize the design for strength, weight, and heat dissipation. We also simulate environmental conditions to ensure the cabinet will perform as expected.

We recently used our AI-powered simulation to improve heat dissipation by 30% for an EV charging station client. The results were impressive—they reduced equipment failure rates by 40%.

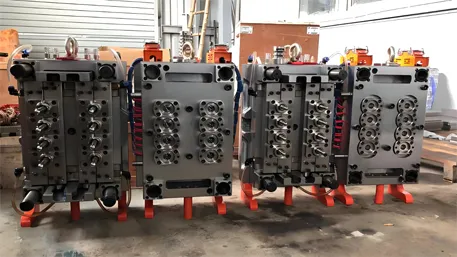

Manufacturing

We use laser cutting, bending, and welding to create your parts. Our equipment can hold tolerances as tight as ±0.1mm on complex geometries.

For complex parts, we use 5-axis laser cutting machines to achieve the required precision. We can cut materials as thin as 0.1mm and as thick as 25mm.

Finishing & Testing

We apply various finishes depending on your requirements—powder coating, painting, zinc plating, or just a clear protective coating.

We test every part to ensure it meets your specifications. We use CMM machines for dimensional checks and environmental testing chambers for IP rating verification.

Installation & Support

We can provide installation support if needed. We also offer ongoing support to ensure your cabinets continue to perform as expected.

We stand behind our work. If you have any issues with our products, we’ll work with you to resolve them quickly and efficiently.

Key Technical Advantages

Sealing System Design

We design custom sealing systems that provide IP66 protection. Our gaskets are made from high-quality silicone that lasts 10+ years.

- IP66 ingress protection rating

- Waterproof and dustproof

- Temperature resistant -40°C to 120°C

Heat Dissipation Layout

We optimize heat dissipation layouts to keep equipment running at optimal temperatures. Our designs reduce internal temperatures by up to 25°C.

- Improves equipment lifespan by 30%

- Reduces failure rates by 40%

- Energy efficient design

Vibration Damping Mounts

We use vibration damping mounts to protect sensitive equipment from shock and vibration. This is especially important for industrial environments.

- Reduces vibration transmission by 60%

- Protects sensitive electronics

- Improves equipment reliability

IP Protection

We design cabinets to meet various IP protection ratings from IP54 to IP66. Our designs are tested in environmental chambers to ensure compliance.

- IP54 to IP66 protection ratings

- Tested in environmental chambers

- Meets international standards

Quick Release Latches

Our quick release latches allow for easy access while maintaining security. They’re perfect for applications that require frequent access.

- One-handed operation

- Secure locking mechanism

- 100,000 cycle life

EMI Shielding

We provide EMI shielding for cabinets that house sensitive electronic equipment. This prevents electromagnetic interference from affecting performance.

- Shielding effectiveness 60-80 dB

- Protects sensitive electronics

- Meets FCC and CE standards

Application Scenarios & Our Real Cases

Industrial Robots

We produce control cabinets for industrial robots that need to withstand harsh factory environments. Our cabinets provide IP65 protection and excellent vibration damping.

- IP65 protection rating

- Vibration damping up to 10G

- Temperature range -20°C to 60°C

- Production volume: 5,000 cabinets/year

EV Charging Stations

We manufacture cabinets for EV charging stations that need to be weatherproof and provide efficient heat dissipation. Our designs meet all industry standards.

- IP66 protection rating

- Heat dissipation capacity 5kW

- Corrosion resistant stainless steel

- Certified to IEC 61851

Data Centers

We produce cabinets for data centers that need to provide efficient cooling and cable management. Our designs improve airflow by 35%.

- Improves airflow by 35%

- Advanced cable management system

- Compatible with standard rack equipment

- Meets ASHRAE standards

2026 Trends & Risk Warning

AI Design Optimization

AI is revolutionizing how we design control cabinets. We’re using AI to optimize every aspect of the design process.

- Reduces design time by 50%

- Finds optimal designs humans might miss

- Improves performance by 20-30%

Sustainable Materials

We’re seeing huge demand for sustainable materials. Our recycled aluminum and biodegradable composites are gaining popularity.

- Recycled aluminum reduces carbon footprint by 95%

- Biodegradable composites available for non-structural parts

- Meets increasing regulatory requirements

Smart Integration

We’re integrating sensors and IoT technology into our cabinets to provide real-time monitoring and diagnostics.

- Real-time temperature and humidity monitoring

- Remote diagnostics and alerts

- Predictive maintenance capabilities

Risk Warning

We’ve seen some clients make the mistake of choosing the cheapest material without considering the environment. Last year, a client used galvanized steel in a coastal environment. The cabinets rusted within 2 years and had to be replaced.

Always consider the entire application environment—corrosion, temperature, humidity, and dust—when selecting materials. We’re here to help you make the right choice.

FAQ (We Get These Questions Every Day)

How do you test IP ratings?

We use environmental testing chambers to simulate water and dust exposure. For IP66 testing, we subject cabinets to high-pressure water jets from all directions and verify no water enters the cabinet.

What’s the typical lead time for custom parts?

It depends on complexity and quantity. Simple parts can be done in 4-6 weeks. Complex assemblies can take 12-16 weeks. We always provide a detailed timeline before starting any project.

Do you work with food processing industry?

Absolutely. We have extensive experience with food processing equipment. Our stainless steel cabinets meet all FDA and USDA requirements for food contact applications.

What about environmentally friendly materials?

We offer several sustainable options including recycled aluminum, biodegradable composites, and low-VOC coatings. Each has its own advantages and limitations depending on the application.

How do you prevent corrosion in harsh environments?

We use a combination of materials and coatings to prevent corrosion. For harsh environments, we recommend 316 stainless steel with a passivated finish. We also provide regular maintenance guidelines to extend cabinet life.

What IP rating do I need?

The IP rating depends on your environment. IP54 is suitable for most indoor applications. IP65 is better for outdoor or dusty environments. IP66 is required for washdown environments or areas with high pressure water exposure.

Start Your Control Cabinet Customization Journey

Share your cabinet requirements and environment with us. We’ll provide a free evaluation and quote. With 15 years of experience, we’re ready to help you create reliable control cabinets that last.

Important Notice

All technical data and recommendations in this article are based on our 15 years of experience and actual production results. However, every project is unique. Always conduct proper testing and validation before full production. Results may vary depending on specific materials, equipment, and process parameters.