Silicone and plastic molds are essential tools in the manufacturing industry, enabling the production of intricate and precise components across various sectors. These molds combine the flexibility and durability of silicone with the versatility and strength of plastic, making them ideal for a wide range of applications.

1. Production Process of Silicone and Plastic Molds

Design Conceptualization: Begins with the creation of a detailed design, often using CAD software, to ensure precision and accuracy.

Mold Material Selection: Based on the desired outcome, appropriate silicone and plastic materials are chosen for the mold.

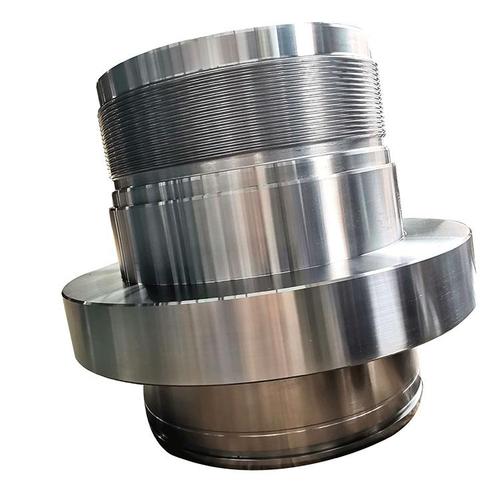

Mold Construction: The mold is constructed through precision machining and molding processes, ensuring all dimensions and specifications are met.

Quality Control: Rigorous inspections are conducted to verify the mold’s integrity and functionality before it enters the next stage.

Final Assembly: Once approved, the mold is assembled and prepared for the molding process.

2. Processing Steps of Silicone and Plastic Molds

Mold Preparation: The mold surface is cleaned and treated to ensure optimal bonding with the molding material.

Material Injection: The selected silicone or plastic material is injected into the mold under controlled conditions.

Cooling and Solidification: The mold is allowed to cool, allowing the material to solidify into the desired shape.

Ejection: The molded part is carefully ejected from the mold, ensuring no damage occurs.

Post-Processing: Final touch-ups, such as trimming and polishing, may be required to meet product specifications.

3. Custom Silicone and Plastic Mold Services

Consultation: We offer personalized consultations to understand your specific needs and requirements.

Design Customization: Our design team can tailor the mold design to match your exact specifications.

Prototyping: We provide prototype services to allow for testing and refinement before full-scale production.

Production Management: Comprehensive production management ensures timely delivery and quality assurance.

After-Sales Support: Our support team is available to assist with any issues or modifications post-production.

4. Materials for Making Silicone and Plastic Molds

{Materials}

Silicone

Plastic Resins

{Characteristics}

Heat Resistance: Both materials can withstand high temperatures without deformation.

Flexibility: Silicone offers excellent flexibility, allowing for intricate designs.

Durability: Plastic resins provide long-lasting durability and resistance to wear and tear.

Precision: Both materials can be molded with high precision, ensuring accuracy in final products.

Chemical Resistance: Resistant to various chemicals, making them suitable for a wide range of applications.

5. Materials that Can be Processed with Silicone and Plastic Molds

{Materials}

Thermoplastics

Elastomers

Composites

Metals (through injection molding with special techniques)

{Characteristics}

Versatility: Suitable for a variety of shapes and sizes.

Cost-Effective: Efficient production methods reduce overall costs.

Strength: Capable of producing parts with high tensile and compressive strengths.

Aesthetic Appeal: Can achieve smooth finishes and vibrant colors.

Environmental Compatibility: Many materials are recyclable and eco-friendly.

6. Processing Techniques for Silicone and Plastic Molds

Injection Molding: A widely used technique for producing parts in high volumes.

Compression Molding: Suitable for larger, thicker parts requiring high pressure.

Transfer Molding: Used for small, intricate parts with tight tolerances.

Blow Molding: Ideal for hollow, thin-walled parts like bottles and containers.

Vacuum Forming: A cost-effective method for producing large, flat sheets into three-dimensional shapes.

7. Equipment for Silicone and Plastic Mold Production

Injection Molding Machines: Equipped with precision control systems for accurate material injection and mold clamping.

Compression Molding Presses: Capable of applying high pressures to ensure proper mold filling.

CNC Machines: Used for mold construction and intricate machining processes.

Material Handling Equipment: Ensures efficient and safe movement of materials throughout the production process.

Quality Control Equipment: Including calipers, micrometers, and coordinate measuring machines (CMMs) for precise measurements and inspections.

Custom Silicone and Plastic Mold Services FAQ

Q: Can I get a custom mold design?

A: Yes, our design team can create a custom mold based on your specific requirements.

Q: What is the lead time for mold production?

A: Lead times vary based on complexity and volume. We will provide a detailed timeline during consultation.

Q: Can I test a prototype before full production?

A: Absolutely. We offer prototype services to ensure your design meets expectations before committing to full-scale production.

Q: What materials can you process?

A: We can process a wide range of materials, including thermoplastics, elastomers, composites, and certain metals.

Q: Do you offer after-sales support?

A: Yes, our support team is available to assist with any issues or modifications post-production.

By leveraging our expertise in silicone and plastic mold production, we can help you bring your innovative designs to life, ensuring precision, quality, and cost-effectiveness throughout the entire process.