In the era of automotive personalization and premium driving experience upgrades, the steering wheel, as the core interface between driver and vehicle, directly influences driving feel. Traditional standardized steering wheels fall short in ergonomic adaptation, material customization, and functional integration. Custom steering wheels, however, leverage data-driven design, advanced manufacturing, and personalized functionality to transform from “generic control” to “exclusive driving experiences.” This article explores how to create ergonomic, aesthetically superior, and highly functional custom steering wheels through customization value, core processes, and innovative features.

1. Why Standard Steering Wheels Fail to Meet Premium Driving Needs

Q: What Defines the Core Advantages of Custom Steering Wheels?

Standard steering wheels, mass-produced with uniform molds and processes, face three critical limitations:

- Ergonomic Mismatch: Fixed dimensions (typically 360-380mm diameter, 32-35mm grip circumference) and arc designs fail to accommodate diverse hand sizes and gripping habits, causing hand fatigue during long drives.

- Generic Materials & Tactility: Common plastics and ordinary leather lack premium texture, with unstable friction coefficients (0.4-0.6 dry, 0.2 wet), increasing slip risks during emergency maneuvers.

- Limited Functionality: Difficulty integrating advanced features like heating, ventilation, or haptic feedback, coupled with poorly optimized button layouts, undermines driving safety.

Custom steering wheels prioritize “driver-specific experiences”:

- Full-Dimension Personalization:

- Size Tailoring: Hand 3D scanning data adjusts diameter (340-400mm), grip circumference (30-38mm), and curvature, improving palm fit by 60% and reducing grip fatigue by 30%.

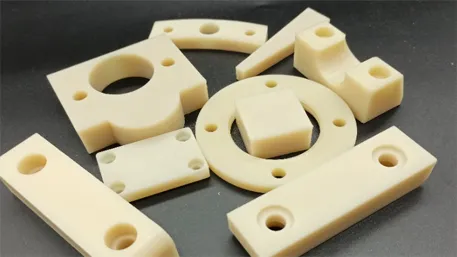

- Material Selection: Offers 10+ premium materials like Alcantara (0.7 dry/0.5 wet friction), carbon fiber (40% weight reduction), and Nappa leather (Shore A 20-30 softness) for diverse scenarios.

- Data-Driven Optimization: Analyzes driving behaviors (steering force, grip position) to optimize button layouts and multifunctional zones, enhancing reach efficiency by 40% and reducing misoperation rates by 50%.

2. Core Processes for Enhanced Driving Experience

1. Digital Design & Ergonomic Validation

- 3D Scanning & Modeling: Handheld laser scanners (±0.1mm precision) capture hand contours, combining with seat adjustment data to create CAD models of custom steering wheel surfaces.

- Ergonomic Simulation: AnyBody software simulates hand force distribution across driving postures, optimizing surface textures (0.3-0.5mm depth) and grip arcs for uniform pressure dispersion.

- Rapid Prototyping: 3D-printed (SLS, 0.05mm layer thickness) 1:1 models enable real-world testing, shortening design iteration from 20 to 7 days.

2. Premium Manufacturing: Crafting Perfection from Material to Finish

- Carbon Fiber Weaving: Pre-preg layering with T700 carbon fiber (≥4900MPa tensile strength), cured in an autoclave (180°C, 8bar), creates 2-3mm lightweight structures with torsional stiffness ≥500N·m/deg.

- Leather/Alcantara Wrapping:

- Laser Cutting: CO₂ lasers (50W, ±0.2mm precision) cut materials to ensure grain alignment and stitching accuracy.

- Hand Stitching: Artisans use saddle stitching (3-4mm pitch) with ultrasonic welding (40kHz) for critical areas, achieving 200N/5cm tensile strength and 3x durability.

- Surface Treatments:

- Anodizing: Hard anodizing (25μm thickness, HV≥500) on aluminum parts enhances wear and corrosion resistance.

- Micro-Arc Oxidation: Ceramic coatings (30μm, >10MΩ insulation) on magnesium alloys balance lightweighting and functionality.

3. Smart Function Integration & Data Control

- Multifunctional Modules:

- Capacitive Buttons: Embedded sensors (response time <10ms) support customizable functions (voice control, drive mode switching).

- Heating/Ventilation: Nano-carbon heating films (5°C/min heating) and micro-fans (noise <25dB) with PID temperature control (±1°C precision).

- Production Monitoring: Real-time tracking of 30+ parameters (wrapping tension 5-8N, welding temp 120-150°C) with AI-driven compensation, boosting yield from 82% to 97%.

- Testing & Calibration: CMM (±0.03mm precision) verifies mounting holes, torque testers (100N·m range) ensure steering column strength, with data uploaded to MES for digital twin records.

3. Innovative Features: Redefining Driving Interaction

1. Health Monitoring & Intelligent Feedback

- Heart Rate Sensing: PPG sensors (100Hz sampling) in the grip monitor heart rate variability (HRV), triggering vibrations (2-5Hz) and lights to warn of fatigue (HRV drop >30%).

- Force Feedback: Magnetorheological dampers (<1ms response) adjust steering resistance for scenarios like curves or wet roads, simulating realistic road feel.

2. Personalized Interaction Design

- Programmable Lighting: RGB strips (0-1000cd/m² brightness) on spokes support custom colors and breathing patterns, visualizing drive modes (red flash for sport, blue gradient for comfort).

- Voice-Touch Integration: Pressure-sensitive touch zones (0.1N resolution) combined with voice recognition enable hands-free commands (e.g., “navigate to destination”).

4. Quality Control: Rigorous Standards from Material to Finished Product

1. Multi-Dimensional Testing

- Material Screening:

- Leather: Martindale test (50,000 cycles without damage), formaldehyde ≤0.05mg/m³ (OEKO-TEX 100 compliant).

- Carbon Fiber: Ultrasonic C-scan (porosity <1%), interlaminar shear strength ≥80MPa.

- Finished Product Testing:

- Fatigue Life: 2 million steering cycles (±90° angle, 3N·m torque) with no structural cracks.

- Environmental Resistance: -40°C to 85°C testing for 24 hours each, with no deformation or brittleness.

- Safety Compliance: Passes FMVSS 203 crash tests (12.8km/h impact) with no sharp fragments and compliant crumple performance.

2. Intelligent Defect Prevention

- First-Article 12-Check System: Engineers verify 40+ metrics (material batch, module assembly, surface flaws) to intercept defects.

- AI Visual Inspection: Line-scan cameras (12,000dpi) detect stitching deviations (>0.5mm) or scratches (>1mm) in 0.5 seconds, with a miss rate <0.002%.

5. Small-Batch Customization: Balancing Efficiency and Cost

Q: Does High-Precision Customization Mean High Costs?

Three innovations achieve 50% shorter lead times and 30% cost reduction:

- Modular Function Library: 15+ standardized modules (heating, touch, monitoring) with 75% reuse, cutting development costs by 40%.

- Flexible Production Lines: Robotized quick-change systems (<3-minute mold swaps) and AGV logistics enable small-batch (10-500 units) production, with 88% equipment utilization.

- Virtual Validation: Digital twin simulations reduce physical prototyping by 80%, shortening R&D from 45 to 22 days.

6. Key Considerations for Choosing Custom Steering Wheels

- Data Acquisition Capability: Suppliers must have professional 3D scanners and driving behavior analysis systems for precision customization.

- Process Complexity: Full-spectrum capabilities in carbon fiber processing, smart module integration, and premium wrapping to meet diverse needs.

- Certifications & Compliance: ISO 9001, IATF 16949, and regional safety certifications (e.g., ECE R12) for regulatory compliance.

Conclusion

Custom steering wheels embody “personalized control through data” and “human-vehicle synergy through craftsmanship.” As automobiles evolve toward intelligence and individuality, custom solutions with “data-driven design and premium manufacturing” are key to elevating driving quality. From track-ready precision feedback to daily comfort, custom steering wheels redefine every turn with “millimeter-level precision and intelligent interaction,” setting new standards for driving pleasure and safety.

(Contact us today for your exclusive custom steering wheel solution and free 3D simulation experience)