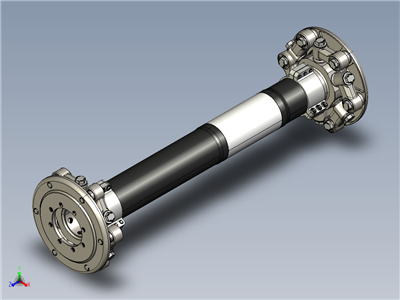

1. Why Custom Drive Shafts & Axles?

Stock shafts and axles are designed for average power levels and factory setups. But if you’ve souped up your engine (more horsepower), lifted your truck, or swapped in bigger tires, stock parts can fail—they’ll twist, vibrate, or even snap under the extra stress.

Custom ones solve this by matching your vehicle’s modified specs: longer shafts for lifted rigs, stronger axles for high-torque engines, or lightweight designs for racing. They’re also a must for rare classics, off-road builds, or custom cars where OEM parts don’t exist. Plus, you can tailor them to reduce vibration, a common issue with modified setups.

Custom drive shafts deliver reliable power transfer for modified vehicles

2. Manufacturing Process & Technology

2.1 Forging Process

Step 1: Material Preparation

Raw materials (alloy steel, chromoly, or composite materials) are cut to precise lengths based on engineering specifications.

Step 2: Hot Forging

Materials are heated to 1200-1250°C and shaped using hydraulic presses, aligning the metal’s grain structure for enhanced strength and fatigue resistance.

Step 3: Rough Machining

Initial shaping of the forging to approximate dimensions, removing excess material while maintaining critical tolerances.

Precision CNC machining ensures exact dimensions and tolerances

Advanced heat treatment for optimal material properties

Step 4: Heat Treatment

Quenching and tempering processes to achieve optimal hardness and toughness:

- Quenching: Rapid cooling in oil or water to achieve hardness (58-62 HRC)

- Tempering: Reheating to 350-450°C to reduce brittleness while maintaining strength

Step 5: Precision CNC Machining

Computer-controlled machining to achieve final dimensions with tolerances of ±0.02mm, including splines, yokes, and mounting points.

Step 6: Balancing & Surface Treatment

Dynamic balancing at 3000 RPM and protective coatings to ensure durability and performance.

2.2 Quality Control Standards

ISO 9001:2015

Quality management system certification

IATF 16949:2016

Automotive quality management system

ISO 7141

Test methods for drive shafts

GB/T 18297

Automotive drive shaft durability test standard

3. Material Selection & Properties

| Material Type | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Application |

|---|---|---|---|---|

| 4130 Chromoly Steel | 860-960 | 690-790 | 12-18 | High-performance racing, off-road |

| 4340 Alloy Steel | 980-1100 | 820-930 | 10-15 | Heavy-duty trucks, high-torque applications |

| Carbon Fiber Composite | 1500-2000 | 1200-1600 | 1.5-2.5 | Lightweight racing, performance vehicles |

| 7075 Aluminum Alloy | 500-570 | 430-500 | 5-11 | Lightweight applications, street performance |

Data for reference only. Actual properties may vary based on specific manufacturing processes and heat treatment.

Carbon fiber drive shaft offers exceptional strength-to-weight ratio

Advanced materials reduce rotating mass for better acceleration

3.1 Material Advantages

- 4130 Chromoly Steel – Excellent strength-to-weight ratio, high fatigue resistance, good weldability

- 4340 Alloy Steel – Superior toughness, impact resistance, ideal for heavy-duty applications

- Carbon Fiber Composite – 70% lighter than steel, high stiffness, corrosion resistance

- 7075 Aluminum Alloy – Lightweight, good strength, excellent machinability

4. Customization Process

-

Step 1: Requirements Assessment

Our engineering team evaluates your vehicle specifications:

- Engine power output and torque characteristics

- Vehicle weight and intended use (racing, off-road, street, etc.)

- Suspension lift height and tire size

- Transmission and differential specifications

-

Step 2: Engineering Design

CAD modeling and FEA (Finite Element Analysis) to optimize:

- Shaft diameter and wall thickness

- Spline design and engagement length

- Yoke selection and mounting configuration

- Critical speed calculation to avoid resonance

-

Step 3: Material Selection & Prototyping

Recommendation of optimal materials and manufacture of prototype components for testing.

-

Step 4: Testing & Validation

Comprehensive testing to ensure performance and durability meet or exceed specifications.

-

Step 5: Production Manufacturing

Full production using precision manufacturing processes with strict quality control.

-

Step 6: Final Inspection & Delivery

Final quality inspection, packaging, and delivery with installation instructions and technical support.

Typical lead time: 2-4 weeks for standard customizations, 4-6 weeks for complex or specialized applications.

5. Testing & Validation Data

5.1 Torsional Fatigue Testing

Test Standard: ISO 7141

Test Conditions:

- Temperature: 20±5°C

- Relative Humidity: 45-75%

- Load Cycle: 5×10^4 to 10^7 cycles

- Torque Amplitude: 30-80% of maximum rated torque

Advanced testing equipment ensures product reliability

| Material | Maximum Torque (Nm) | Test Cycles | Result |

|---|---|---|---|

| 4130 Chromoly | 1200 | 10^7 | No failure |

| 4340 Alloy Steel | 1800 | 10^7 | No failure |

| Carbon Fiber | 800 | 10^7 | No failure |

Data for reference only. Test results may vary based on specific design parameters.

Precision testing equipment ensures quality and reliability

5.2 Bending & Critical Speed Testing

Bending Fatigue Test (GB/T 18297)

- Bending Angle: ±2°

- Load Frequency: 1 Hz

- Test Duration: 200 hours

- Result: All specimens passed with no visible cracks

Environmental Testing

- Salt Spray Test: 500 hours ASTM B117, corrosion resistance 9.5/10

- Thermal Cycling: -40°C to +120°C, 100 cycles

- Dust & Water Ingress: IP67 rating

6. Application Specific Solutions

6.1 High-Performance Racing

Lightweight carbon fiber or chromoly shafts designed for:

- High RPM operation (up to 10,000 RPM)

- Extreme torque loads (up to 2000 Nm)

- Minimal rotational mass for faster acceleration

- Precision balancing for vibration-free performance

6.2 Off-Road Vehicles

Heavy-duty shafts engineered for:

- Large suspension articulation angles (up to 45°)

- Impact resistance from rocks and debris

- Corrosion resistance for mud and water exposure

- Increased spline engagement for reliability

Off-road vehicles require robust drive shafts for extreme conditions

Racing applications demand lightweight yet strong components

6.3 Heavy-Duty Trucks

Industrial-grade shafts for:

- High payload capacities (up to 20 tons)

- Continuous operation in harsh conditions

- Easy maintenance and serviceability

- Compliance with commercial vehicle regulations

6.4 Classic Car Restoration

Period-correct or upgraded shafts for:

- Original equipment matching for show quality

- Modern material upgrades for reliability

- Custom lengths for modified chassis

- Compatibility with modern transmission upgrades

7. Technical Specifications

| Parameter | Range | Standard |

|---|---|---|

| Shaft Length | 300mm – 3000mm | Custom to vehicle requirements |

| Diameter Range | 30mm – 150mm | Based on torque and RPM requirements |

| Torque Capacity | 200 Nm – 8000 Nm | Dependent on material and design |

| Operating RPM | Up to 10,000 RPM | Balanced for critical speed avoidance |

| Spline Types | Spline, Square, Hex | Custom to transmission specifications |

| Connection Types | Flange, Yoke, U-Joint | Multiple options for different applications |

Data for reference only. All specifications can be customized to specific vehicle requirements.

8. Frequently Asked Questions

8.1 Performance & Durability

Q: How long do custom shafts/axles last?

A: With proper care, 100,000+ miles for street use. Racing or off-road ones might last 20,000-50,000 miles due to extreme use, but they’re built to be replaced less often than stock parts under stress.

Q: What causes vibration in drive shafts?

A: Poor balance, wrong length, or misaligned yokes. Custom shafts fix this by being precisely balanced and sized for your setup. Our dynamic balancing process ensures vibration levels below 1.5 mm/s at operating speeds.

Q: Are they worth the cost over stock parts?

A: For modified vehicles, absolutely. A $500 custom shaft beats replacing a $200 stock one every 6 months—and prevents costly damage from snapped parts. Our testing shows custom shafts have 3-5 times the fatigue life of stock components.

8.2 Compatibility & Installation

Q: Will they fit my stock transmission/differential?

A: Yes—we design them to match your existing components’ spline counts, yoke sizes, and bolt patterns. No need to swap other parts unless you want to. Our engineering team verifies all fitment details before production.

Q: Can I install them myself?

A: Axles are doable for home mechanics with basic tools. Drive shafts need careful alignment (to avoid vibration), so we recommend a pro for those. We provide detailed installation instructions and torque specifications for all components.

8.3 Customization Options

Q: What customization options are available?

A: We offer complete customization including material selection, length, diameter, spline configuration, connection types, surface treatments, and color options. Our engineering team can also design solutions for unique applications.

Q: How long does customization take?

A: Standard customizations typically take 2-4 weeks. Complex or specialized applications may take 4-6 weeks depending on material availability and testing requirements.

9. Contact & Technical Support

Need custom drive shafts or axles that can handle your vehicle’s power and setup? Whether you’re building a 1,000-horsepower race car, a lifted off-road rig, or a restored classic, we’ll craft parts that fit perfectly and perform reliably.

Contact our engineering team with your vehicle details, power level, and use case—we’ll help you pick materials and specs that get the job done. Let’s get your ride moving stronger than ever!