Automotive steering tie rods are the unsung heroes of your car’s steering system. These metal rods connect your steering rack to the wheel hubs, translating every turn of your steering wheel into precise movement of the front wheels. Think of them as the “link” that makes sure your car goes exactly where you point it. Custom tie rods are built to fit specific vehicles or driving needs, ensuring better control, durability, and reliability than one-size-fits-all parts.

1. Why Custom Steering Tie Rods?

Stock tie rods work fine for regular cars and daily driving, but they fall short if you’ve modified your ride or have specific needs. Maybe you’ve lifted your truck, lowered your sports car, or built a race car—stock rods just won’t match the new geometry. Custom rods fix that by fitting perfectly with your modified suspension.

They’re also a lifesaver for older or rare vehicles where OEM parts are discontinued. Plus, if you want better performance—like stiffer rods for sharper handling or corrosion-resistant ones for off-roading—custom options let you pick features that stock parts can’t offer.

2. How Custom Tie Rods Are Made

Forging: Heating metal (like a blacksmith, but high-tech) and hammering it into shape. This makes the rod super strong, able to handle the stress of tight turns and rough roads.

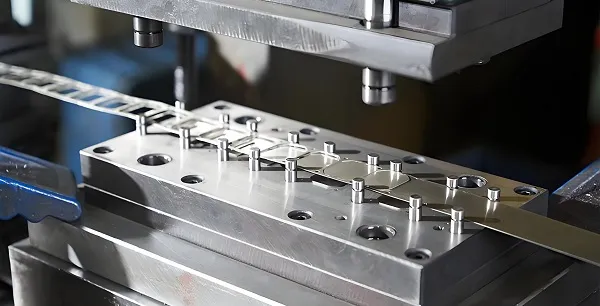

CNC Machining: Using computer-controlled tools to carve out precise ends, threads, and joints. It’s like 3D printing but for metal—ensuring every part lines up perfectly with your steering system.

Thread Rolling: Creating threads (the screw-like parts that connect to other components) by pressing metal, not cutting it. This makes threads stronger and less likely to strip.

Welding: For rods with adjustable ends or reinforced sections, welding joins parts together with high heat, creating bonds that won’t break under pressure.

Heat Treatment: Heating and cooling the metal to make it tough but flexible—so it can handle jolts without bending or snapping.

3. The Process of Making Custom Tie Rods

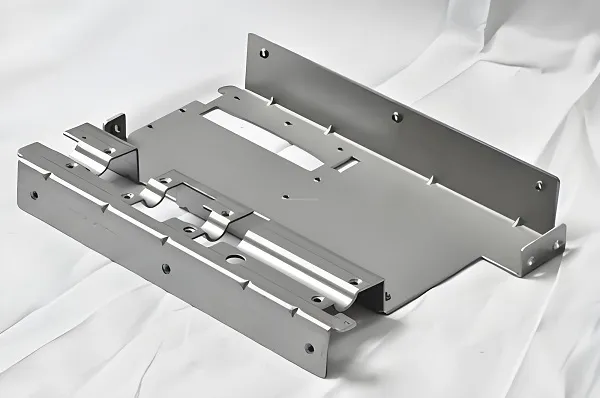

Measure & Design: We start by measuring your car’s steering setup—how long the rod needs to be, where the joints go, and how much movement it needs. CAD software helps design a rod that fits like a glove.

Pick the Metal: Choose materials based on your needs (more on that below).

Shape the Rod: Forged rods are heated and formed; others are cut from solid metal bars using precision tools.

Add Threads & Joints: CNC machines carve threads for adjustable ends, and joints are added to let the rod pivot smoothly.

Strengthen It: Heat treatment makes the metal tough enough to handle thousands of turns and bumps.

Protect It: A rust-resistant coating (like powder coating or galvanizing) is applied to keep it looking and working great for years.

Test It: We check if it fits your car, twist it to ensure flexibility, and test the threads to make sure they won’t strip.

4. Materials for Custom Tie Rods

Alloy Steel: The workhorse of tie rods. Strong, durable, and affordable—great for trucks, SUVs, and daily drivers. Handles heavy loads and rough roads like a champ.

Chromoly Steel: A step up in strength and lightness. Perfect for racing cars or modified vehicles where every ounce of weight and precision counts. It’s more expensive but worth it for performance.

Stainless Steel: Resists rust like a pro. Ideal for coastal areas or off-road vehicles that see a lot of mud, water, or salt.

Each material has its perks—we’ll help you pick based on how you drive and where you live.

5. Where Custom Tie Rods Are Used

Modified Cars: Lowered or lifted vehicles need rods that match their new suspension angles—stock ones just don’t reach or bend right.

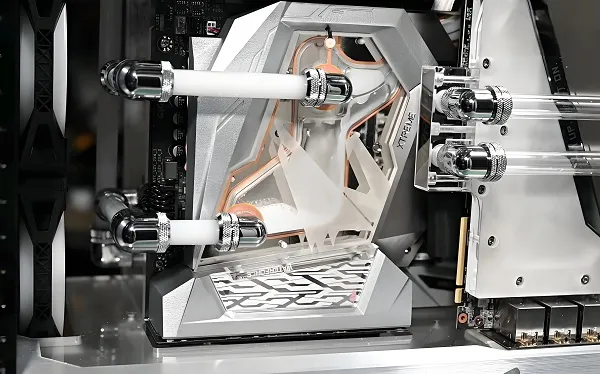

Racing Vehicles: Track cars use stiff, lightweight chromoly rods for instant steering response—no lag when you turn the wheel.

Off-Road Trucks: Heavy-duty alloy steel rods stand up to rocks, ruts, and constant jostling without bending.

Classic Cars: Older rides often need custom rods because original parts are worn out or impossible to find.

Heavy-Duty Vehicles: Trucks that tow or haul heavy loads use reinforced tie rods to handle the extra stress.

6. Extra Features for Better Performance

Adjustable Ends: Let you fine-tune your wheel alignment. No more “close enough”—get your tires pointing exactly where they should.

Grease Fittings: Small ports to add lubricant, keeping joints moving smoothly and preventing wear.

Reinforced Ends: Thicker metal at the joints (where most stress happens) to prevent bending or breaking.

Corrosion Resistance: Special coatings or stainless steel construction to fight rust—critical for drivers in wet or salty climates.

7. Common Questions About Custom Tie Rods

How long do custom tie rods last?

Depends on material and use. Alloy steel rods last 5–10 years for daily driving; off-road or racing rods might need replacement every 2–3 years from hard use.

Can I install them myself?

If you’re handy with a wrench and have alignment tools, maybe. But we recommend a pro—badly installed rods can make your steering loose or unsafe.

Will they make my steering feel different?

Yes—in a good way. Stiffer rods make steering feel tighter and more responsive. Adjustable ones let you dial in the “feel” you want.

Are they better than OEM rods?

For stock cars, OEM works. But for modified, racing, or older vehicles, custom rods are more reliable and better suited to your needs.

Do they come with a warranty?

Most do—1–5 years, depending on the material. We stand behind our rods, so if something breaks (that’s not from abuse), we’ll fix it.

Need custom tie rods that fit your ride perfectly? Whether you’re building a race car, fixing up a classic, or upgrading your truck, we’ll make rods that match your needs. Tell us your vehicle model, modifications, and how you drive in the comments. Our team will help you pick materials, features, and specs that make your steering feel sharp and reliable—let’s get started!